R-shaped open iron core and application thereof in Hall current sensor

An open iron core, Hall current technology, applied in the direction of transformer/inductor core, transformer/inductor parts, transformer/inductor coil/winding/connection, etc., can solve the reduction of magnetic flux density and sensor temperature drift , sensor output power consumption and other problems, to achieve the effect of reducing flux leakage and magnetic circuit loss, reducing built-in impedance and power consumption, and improving output drive capability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

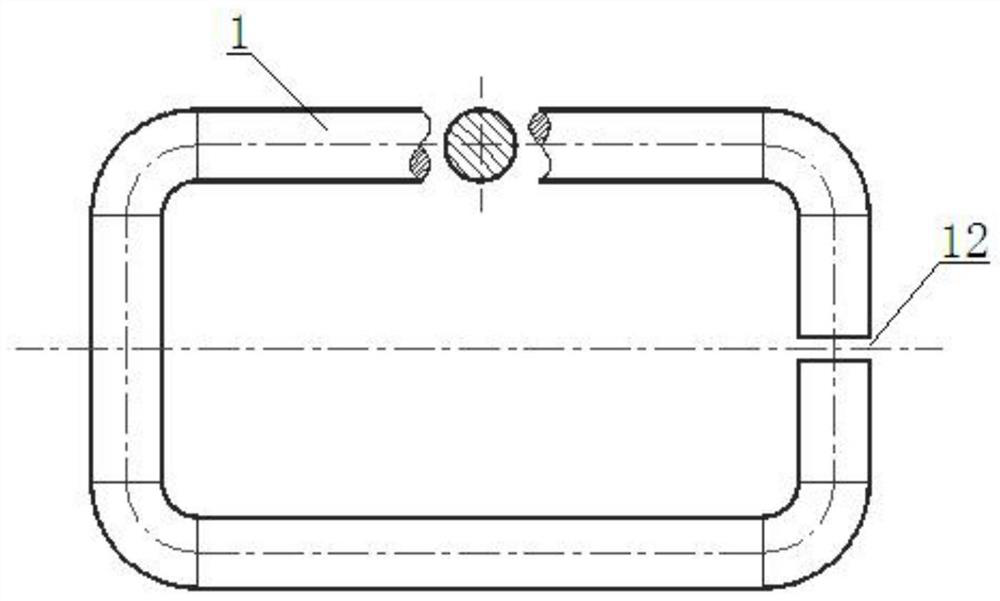

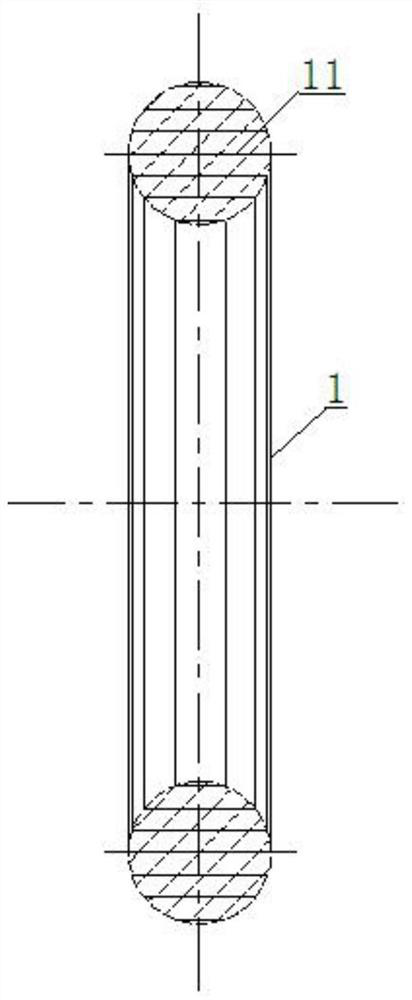

[0043] see Figure 1~4 , an R-shaped split iron core 1, specifically a square frame structure with four arc-shaped chamfered arc edges. The R-shaped open iron core 1 is formed by winding a strip-shaped metal sheet 11 from the inside to the outside, and an open air gap 12 is cut out at the side of the non-wound coil. The magnetic permeability of the iron core The cross section is circular.

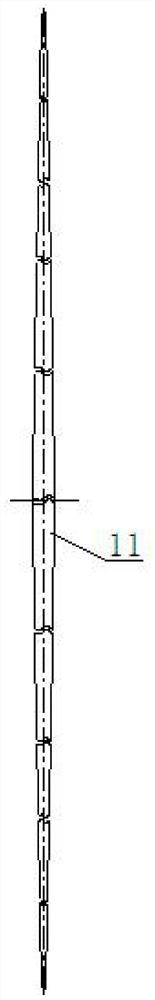

[0044] The metal sheet 11 includes a plurality of end-to-end segments, the thickness of the metal sheet 11 is equal everywhere and the width decreases from the middle to both ends step by step, the width of each part in the same segment is equal, and between adjacent segments There is a transition connection section with gradually changing width, wherein the width of the middle section is equal to the diameter of the magnetic section of the iron core, and the widths of the two sections that are symmetrical about the position of the middle section are equal, and the length of each section i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com