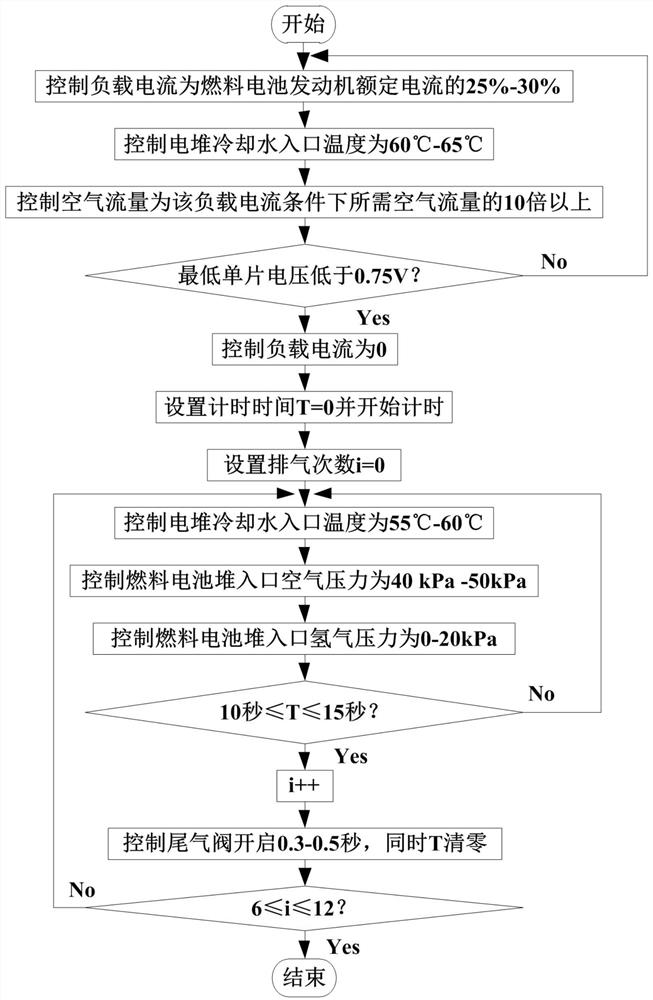

Low-temperature storage control method for purging and dewatering of fuel cell engine

A fuel cell and low-temperature storage technology, applied in fuel cells, electrochemical generators, circuits, etc., can solve problems such as inaccurate measurement, cold start failure, and deterioration of start-up performance, and achieve the goal of improving low-temperature storage and rapid cold start performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

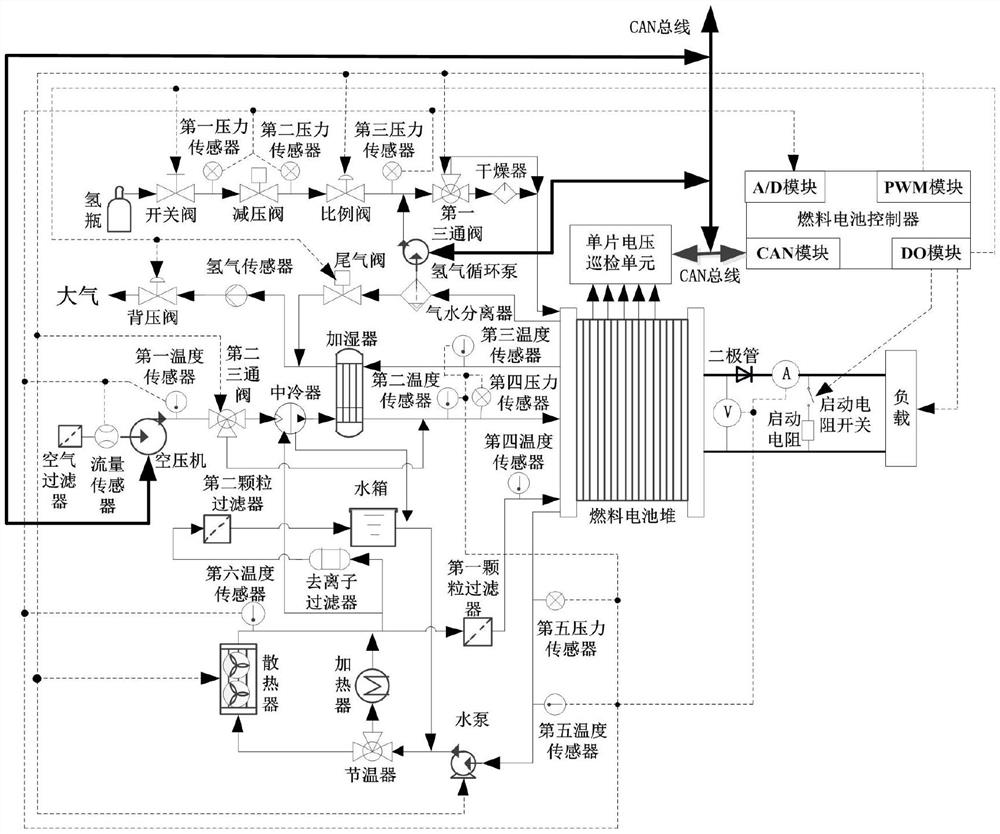

[0022] Such as figure 1 The connection structure of the fuel cell engine control system shown:

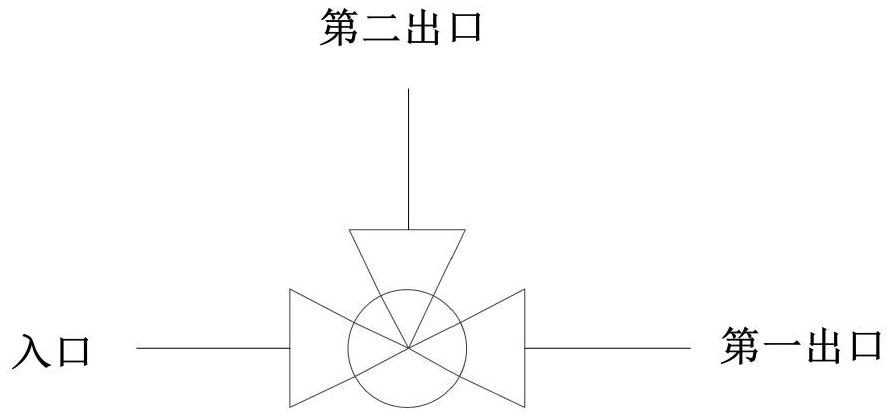

[0023] The outlet of the hydrogen bottle in the hydrogen supply system (in this case, the first three-way valve, the second three-way valve and the branch circuit are added to the existing hydrogen supply system) is sequentially connected with the on-off valve, the first pressure sensor, the pressure reducing valve, The second pressure sensor, the proportional valve, and the third pressure sensor are connected to the inlet of the first three-way solenoid valve. The first outlet of the first three-way solenoid valve is connected to the hydrogen inlet of the fuel cell stack after passing through the dryer. The first three-way The second outlet of the solenoid valve is directly connected to the hydrogen inlet of the fuel cell stack, the hydr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com