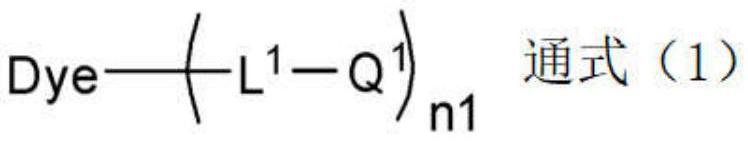

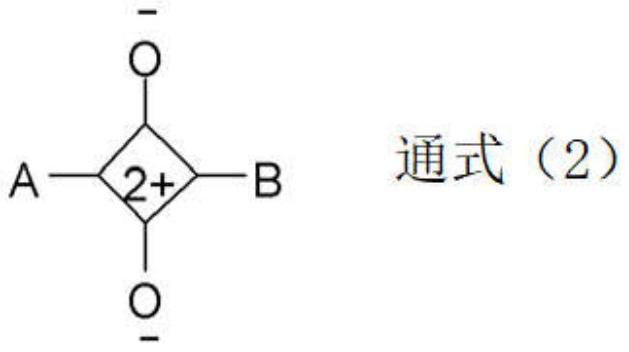

Resin composition, film, optical filter, image display device, solid-state imaging device, and compound

A technology of resin composition and compound, applied in optical components, electrical solid devices, electrical components, etc., can solve the problem of narrow color reproduction area, and achieve the effects of excellent contrast, suppression of fluorescent emission, and excellent light resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0357] The following examples are given to further specifically illustrate the present invention. Materials, reagents, amounts of substances, ratios thereof, operations, and the like shown in the following examples can be appropriately changed within the scope not departing from the gist of the present invention. Therefore, the scope of the present invention is not limited to the following specific examples.

Synthetic example 1

[0358] [Synthesis Example 1] Synthesis of Compound A-1

[0359] [chemical formula 28]

[0360]

[0361] 28.8 parts by mass of thionyl chloride were added to a solution obtained by dissolving 20 parts by mass of N-ethyl-N-2-ethanolaniline in 300 parts by mass of chloroform, followed by heating to reflux for 2 hours. Then, the reaction liquid was added to 300 ml of a saturated potassium carbonate aqueous solution, and the chloroform layer was extracted and then concentrated. Then, it purified by silica gel column chromatography to obtain 14.5 parts by mass of Intermediate 1a.

[0362] Then, weigh 1 mass part of the obtained intermediate 1a, 0.83 mass parts of potassium carbonate, 0.09 mass parts of potassium iodide and 0.7 mass parts of 4-methoxyphenol, and in 20 mass parts of dimethylformamide, It was heated and stirred at a temperature of 85° C. for 24 hours, and then heated and stirred at a temperature of 105° C. for 6 hours. After completion of the reaction, water and ...

Synthetic example 2

[0366] [Synthesis Example 2] Synthesis of Compound B-3

[0367] Compound B-3 was synthesized according to the following scheme.

[0368] [chemical formula 29]

[0369]

[0370]76.5 parts by mass of isopropanol and 132.5 parts by mass of 35% HCl were added to 25 parts by mass of 3'-[bis(2-hydroxyethyl)amino]acetanilide, and heated to reflux for 12 hours. Then, after concentrating the reaction solution, 97.5 parts by mass of N,N-dimethylacetamide, 9.0 parts by mass of triethylamine, 2,2-dimethylbutyryl chloride were added to the obtained liquid at a temperature of 0°C. 12.0 mass, returned to room temperature and stirred for 1 hour. The obtained reaction solution was concentrated, followed by purification by silica gel column chromatography to obtain 25 parts by mass of Intermediate 2. Next, 12.8 parts by mass of tetrahydrofuran, 8.7 parts by mass of trolox, 6.6 parts by mass of 1-(3-dimethylaminopropyl)-3-ethylcarbodiimide hydrochloride were added to 3.4 parts by mass of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com