Preparation method of pure high-protein corn stirring type yoghourt

A stirring, high-protein technology, applied to milk preparations, bacteria used in food preparation, dairy products, etc., can solve the problems of rough taste, powdery feeling, rancid smell and other problems of yogurt, and achieve strong corn flavor and sour taste Soften and overcome the effect of harsh stimulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

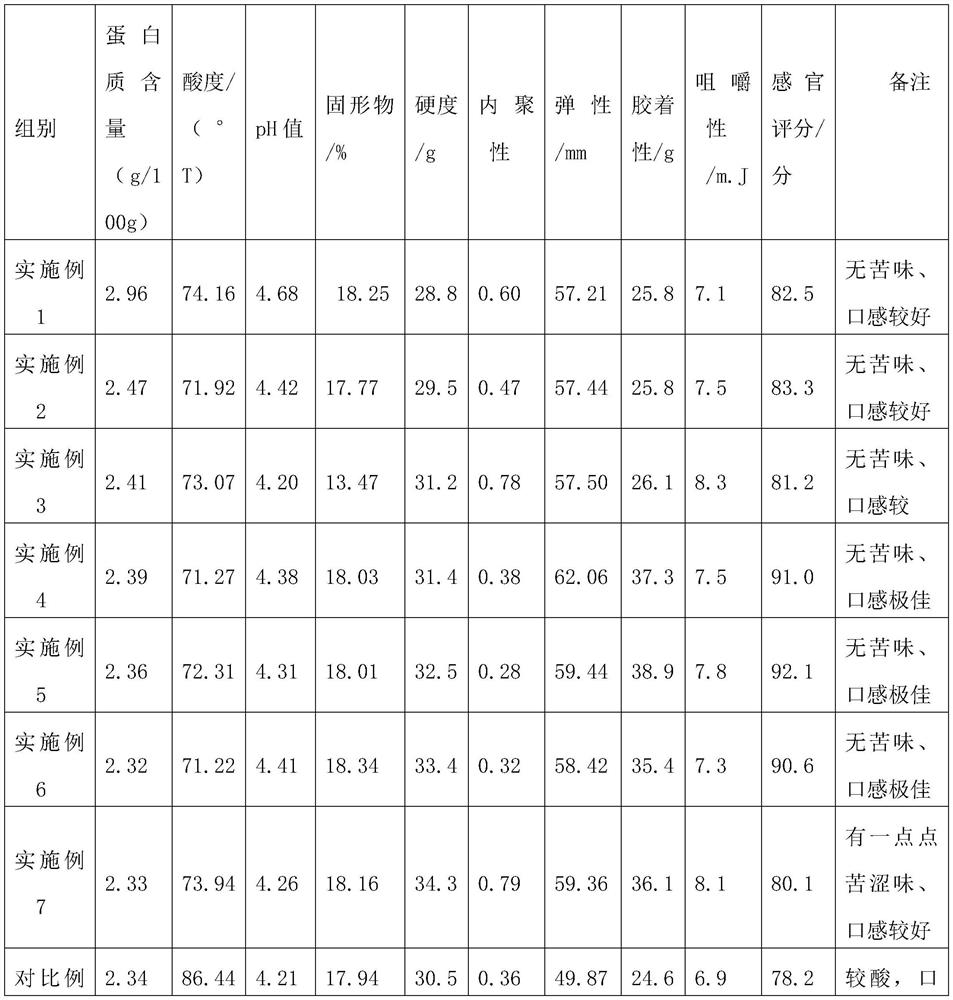

Embodiment 1

[0036] 1) select 2 kg of non-mildew dry corn with an average crude protein content of 20%;

[0037] 2) Mix baking soda, corn and water evenly in a weight ratio of 1:20:200, boil in water for 23 minutes to debitterize, then add citric acid with 40% of the weight of baking soda to neutralize for 2 minutes, and wash the neutralized corn with water 2 times, drain the water, and dry the surface moisture of the corn;

[0038] 3) Add water 5 times the weight of corn, pass through a 40-mesh sieve after beating, and obtain the filtrate;

[0039] 4) Add 7% lactose by weight of the filtrate, and perform homogenization treatment at 15Mpa pressure and 60°C;

[0040] 5) Sterilize in boiling water for 3 minutes, at a temperature of 100°C, and cool to 45°C to obtain a mixture;

[0041] 6) adding a starter to the mixture at a ratio of 2U / ton, and fermenting at 41°C for 5h, the starter being a mixture of Streptococcus thermophilus and Lactobacillus bulgaricus with a weight ratio of 8:1;

[0...

Embodiment 2

[0046] 1) select 2kg of mildew-free fresh corn with an average crude protein content of 24%;

[0047] 2) Mix baking soda, corn and water evenly in a weight ratio of 1:21:210, boil in water for 18 minutes to remove bitterness, then add citric acid with 50% of the weight of baking soda to neutralize for 3 minutes, and wash the neutralized corn with water 3 times, drain the water and dry the surface moisture of the corn;

[0048] 3) adding water 8 times the weight of corn, and passing through a 100-mesh sieve after beating to obtain a filtrate;

[0049] 4) adding 9% glucose by weight to the filtrate, and performing homogenization treatment at 18Mpa pressure and 50°C;

[0050] 5) Sterilize in boiling water for 4 minutes, sterilize at 95°C, cool to 45°C to obtain a mixture;

[0051] 6) adding a starter to the mixture at a ratio of 4U / ton, and fermenting at 45°C for 7h, the starter being a mixture of Streptococcus thermophilus and Lactobacillus bulgaricus with a weight ratio of 11...

Embodiment 3

[0056] 1) Select 2kg of mildew-free frozen corn with an average crude protein content of 36%;

[0057] 2) Mix baking soda, corn and water evenly in a weight ratio of 1:21:210, boil in water for 20 minutes to debitterize, then add citric acid with 60% of the weight of baking soda to neutralize for 2 minutes, and wash the neutralized corn with water 2 times, drain the water, and dry the surface moisture of the corn;

[0058] 3) add water 12 times the weight of corn, pass through a 200-mesh sieve after beating, and obtain the filtrate;

[0059] 4) Add 9% sucrose by weight of the filtrate, and perform homogenization treatment at 20Mpa pressure and 45°C;

[0060] 5) Sterilize in boiling water for 5 minutes, at a temperature of 90°C, and cool to 43°C to obtain a mixture;

[0061] 6) adding a starter to the mixture at a ratio of 6U / ton, and fermenting at 41°C for 8h, the starter being a mixture of Streptococcus thermophilus and Lactobacillus bulgaricus with a weight ratio of 15:1; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com