Nano-selenium-zein composite nano-particle and preparation method thereof

A technology of zein and composite nanoparticles, which is applied in the direction of drug combination, active ingredients of sulfur/selenium/tellurium, non-active ingredients of polymer compounds, etc., can solve the problem of stable nano-selenium and achieve controllable particle size Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

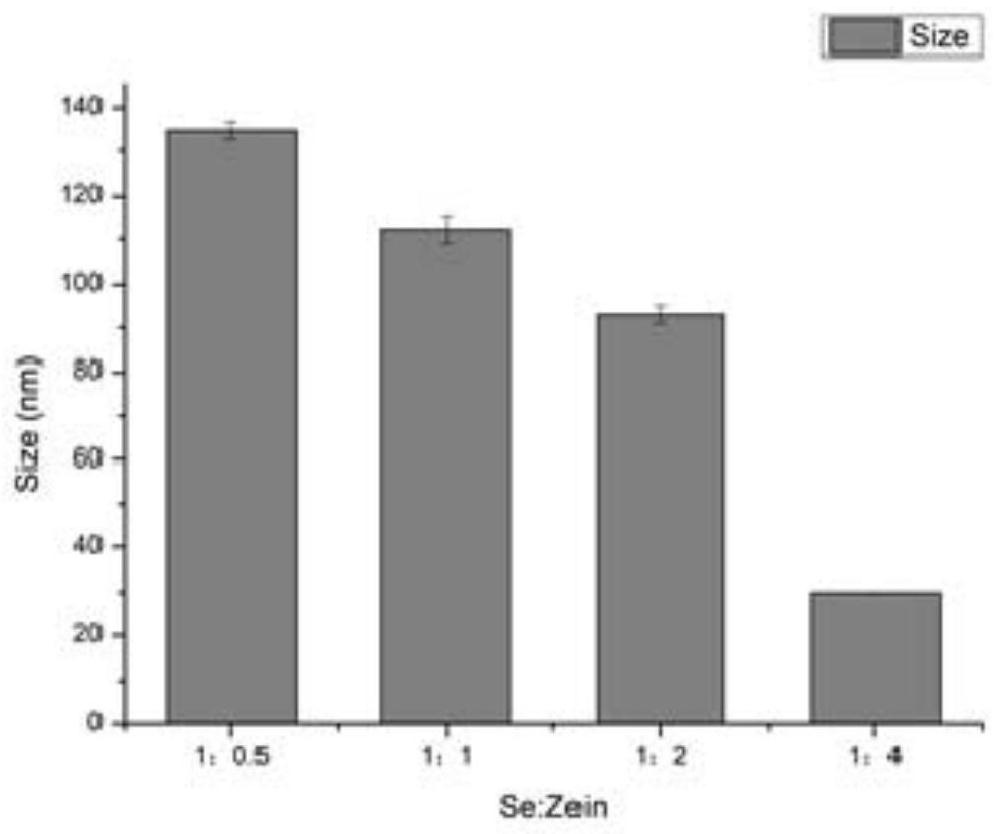

[0034] A nano-selenium-zein composite nanoparticle, the preparation method of which comprises the following steps:

[0035] (1) Weigh 0.1295g of sodium selenite and dissolve it in 250mL of 1% acetic acid to obtain a 3mmol / L sodium selenite solution.

[0036] (2) According to the weight ratio of sodium selenite to zein of 1:4, zein was weighed and dissolved in 8 mL of 85% ethanol solution to obtain a zein solution.

[0037] (3) Pour 50 mL of the sodium selenite solution in step (1) into the zein solution in step (2) under magnetic stirring at one time, stir for 1 minute to make it fully mixed, and then transfer it to the rotary evaporator bottle, 55°C rotary evaporation for 13 minutes, and dilute to 50mL.

[0038] (4) Add ascorbic acid according to the ratio of selenous acid to ascorbic acid molar ratio of 1:4. The nano-selenium-zein composite nanoparticles were prepared by magnetic stirring for 20 minutes.

Embodiment 2

[0040] A nano-selenium-zein composite nanoparticle, the preparation method of which comprises the following steps:

[0041] (1) Weigh 0.2595g of sodium selenite and dissolve it in 250mL of distilled water to obtain a 6mmol / L sodium selenite solution.

[0042] (2) According to the weight ratio of sodium selenite to zein of 1:0.5, zein was weighed and dissolved in 8 mL of 85% ethanol solution to obtain a zein solution.

[0043] (3) Pour 50 mL of the sodium selenite solution in step (1) into the zein solution in step (2) under magnetic stirring at one time, stir for 1 min to make it fully mixed, and then transfer it to a rotary steamer , 55°C rotary evaporation for 13min, and dilute to 50mL.

[0044] (4) Add ascorbic acid according to the ratio of selenous acid to ascorbic acid molar ratio of 1:4. The nano-selenium-zein composite nanoparticles were prepared by magnetic stirring for 20 minutes.

Embodiment 3

[0046] A nano-selenium-zein composite nanoparticle, the preparation method of which comprises the following steps:

[0047] (1) Weigh 0.2595g of sodium selenite and dissolve it in 250mL of distilled water to obtain a 6mmol / L sodium selenite solution.

[0048] (2) According to the weight ratio of sodium selenite to zein of 1:1, zein was weighed and dissolved in 8 mL of 85% ethanol solution to obtain a zein solution.

[0049] (3) Pour 50 mL of the sodium selenite solution in step (1) into the zein solution in step (2) under magnetic stirring at one time, stir for 1 min to make it fully mixed, and then transfer it to a rotary steamer , 55°C rotary evaporation for 13min, and dilute to 50mL.

[0050] (4) Add ascorbic acid according to the ratio of selenous acid to ascorbic acid molar ratio of 1:4. The nano-selenium-zein composite nanoparticles were prepared by magnetic stirring for 20 minutes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com