Water-cooling textile air conditioning system

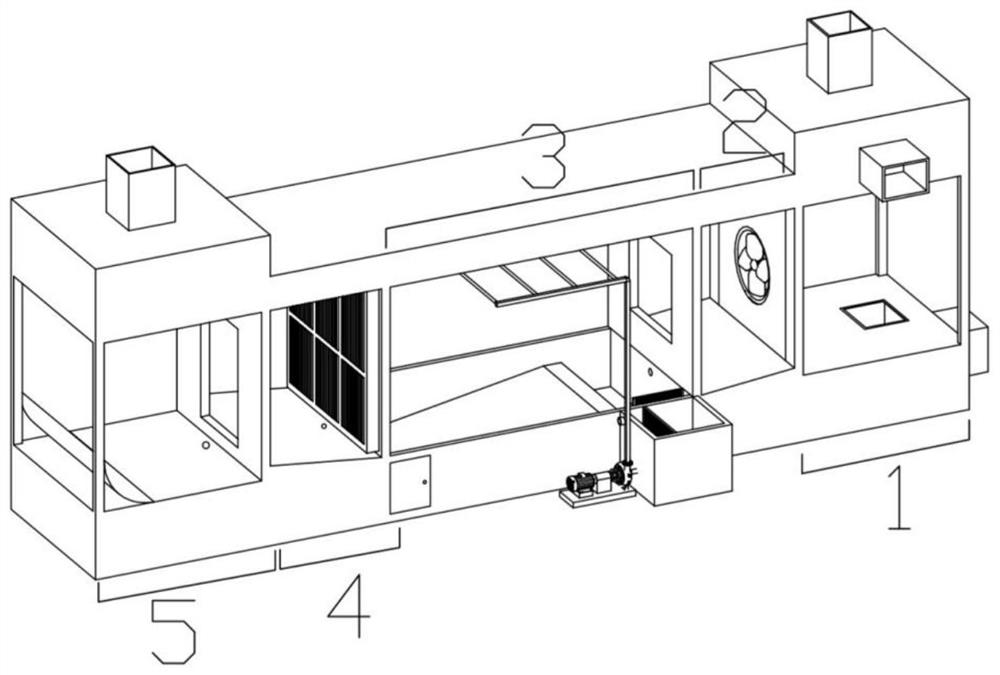

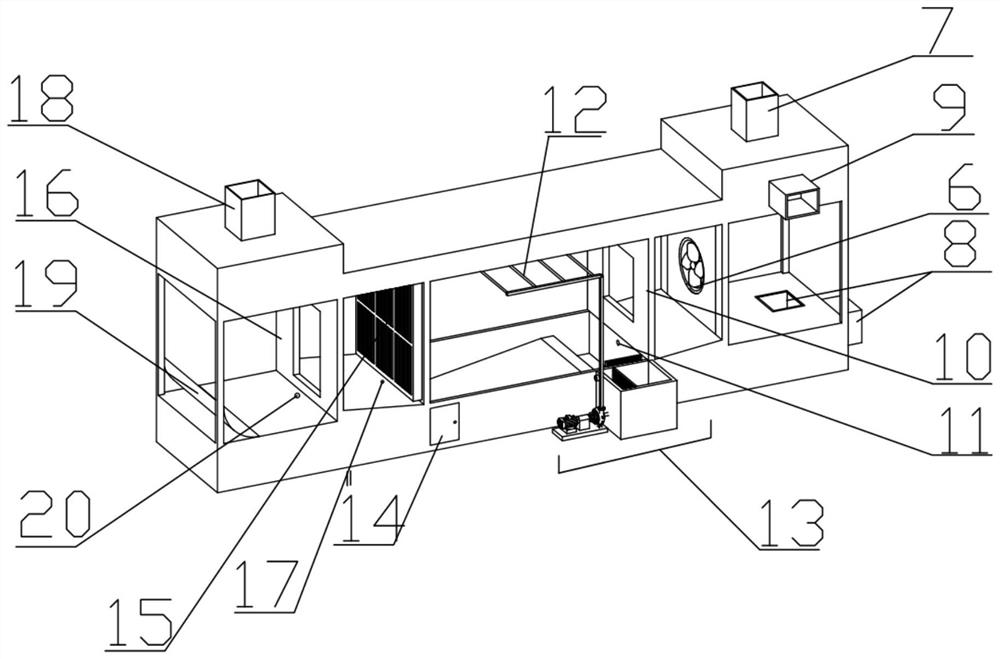

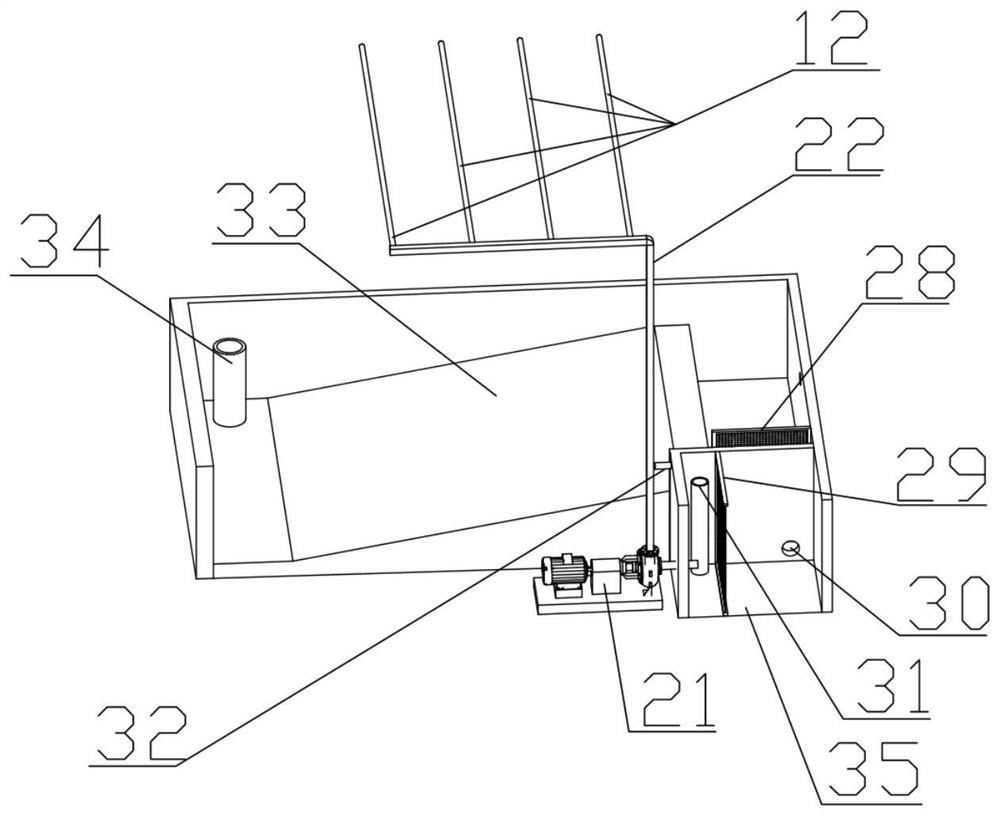

An air-conditioning system and water-cooling technology, which is applied in the air-conditioning system of textile mills and the field of water-cooled textile air-conditioning systems, can solve the problems that the temperature and humidity cannot meet the requirements of fiber work, moisture regain cannot meet the requirements, and the transmission system is complicated Simple, reduce the number of exchanges, reduce the effect of porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] A cashmere carding factory has a workshop area of 2,200 square meters and a workshop motor power of 860KW. The outdoor temperature measured at noon in summer is 40.5°C and the air humidity is 5.5%. The indoor temperature measured before starting up is 42.8°C and the humidity is 38.6%. %, 7.8% after getting off the machine; after 30 minutes of operation of the system, the indoor temperature is 28.7°C, the humidity is 65.6%, the moisture regain of the product is 17.6% before being on the machine, and 17.8% after being off the machine, which can fully meet the needs of production and human comfort degree requirements.

Embodiment 2

[0055] A special animal fiber sliver factory with a workshop area of 1870 square meters and a workshop motor power of 570KW. The outdoor temperature measured at noon in summer is 38.5°C and the air humidity is 428.%; the indoor temperature measured before starting up is 41.2°C and the humidity is 58.9%. 16.4% before the machine, 8.7% after off the machine; after 30 minutes of operation of the system, the indoor temperature is 29.2 ℃, the humidity is 70.5%, the moisture regain of the product is 16.9% before the machine, and 18.3% after the machine, which can fully meet the production requirements. and human comfort requirements.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com