Preparation method and application of attapulgite clay adsorption particles

A technology of attapulgite clay and adsorption particles, which is applied in chemical instruments and methods, adsorption water/sewage treatment, and other chemical processes, and can solve problems such as easy agglomeration and limited adsorption performance, and increase pore volume and specific surface area , increase the pore volume and specific surface area, and the effect of strong adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

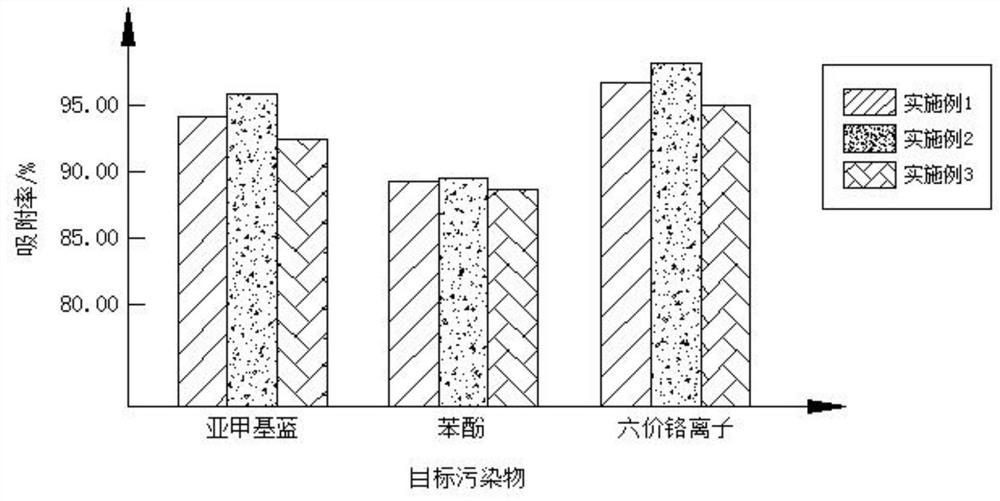

Embodiment 1

[0039] Step 1: Reclaiming pretreatment

[0040] Take attapulgite clay from Guanshan, Jianxi Town, Mingguang City (hereinafter referred to as attapulgite), spread it flat on the site and dry it for at least 3 days (excluding rainy and snowy days), and then roll, crush, and Magnetic separation, sieving (vibration sieving), and powder grinding (ball milling) to a particle size below 1 mm for later use.

[0041] Step 2: First-level high-temperature roasting activation treatment

[0042] Put the attapulgite obtained in step 1 in a muffle furnace, and perform gradient roasting treatment at 120±5°C, 150±5°C, 180±5°C, 210±5°C, and 240±5°C for 25 minutes and 30 minutes respectively , 40min, 50min, 60min, air-cooled with the furnace after roasting;

[0043] Step 3: Pulp milling + primary acid treatment

[0044] Add water to the attapulgite obtained in step 2 to prepare a slurry with a concentration of 32.5wt%, and add a nitric acid solution with a concentration of 2.5mol / L to mix, wher...

Embodiment 2

[0059] Step 1: Reclaiming pretreatment

[0060] Take attapulgite clay from Guanshan, Jianxi Town, Mingguang City (hereinafter referred to as attapulgite), spread it flat on the site and dry it for at least 3 days (excluding rainy and snowy days), and then roll, crush, and Magnetic separation, sieving (vibration sieving), and powder grinding (ball milling) to a particle size below 1 mm for later use.

[0061] Step 2: First-level high-temperature roasting activation treatment

[0062] Put the attapulgite obtained in step 1 in a muffle furnace, and perform gradient roasting treatment at 120±5°C, 150±5°C, 180±5°C, 210±5°C, and 240±5°C for 25 minutes and 30 minutes respectively , 40min, 50min, 60min, air-cooled with the furnace after roasting;

[0063] Step 3: Pulp milling + primary acid treatment

[0064] Add water to the attapulgite obtained in step 2 to prepare a slurry with a concentration of 34.5wt%, and add a nitric acid solution with a concentration of 3.0mol / L to mix, wh...

Embodiment 3

[0079] Step 1: Reclaiming pretreatment

[0080] Take attapulgite clay from Guanshan, Jianxi Town, Mingguang City (hereinafter referred to as attapulgite), spread it flat on the site and dry it for at least 3 days (excluding rainy and snowy days), and then roll, crush, and Magnetic separation, sieving (vibration sieving), and powder grinding (ball milling) to a particle size below 1 mm for later use.

[0081] Step 2: First-level high-temperature roasting activation treatment

[0082] Put the attapulgite obtained in step 1 in a muffle furnace, and perform gradient roasting treatment at 120±5°C, 150±5°C, 180±5°C, 210±5°C, and 240±5°C for 25 minutes and 30 minutes respectively , 40min, 50min, 60min, air-cooled with the furnace after roasting;

[0083] Step 3: Pulp milling + primary acid treatment

[0084] Add water to the attapulgite obtained in step 2 to prepare a slurry with a concentration of 36.5wt%, and add a nitric acid solution with a concentration of 3.5mol / L to mix, wh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com