Iron-carbon micro-electrolysis coupling electrochemical water treatment device and method

An iron-carbon micro-electrolysis and water treatment device technology, applied in the field of water treatment, can solve problems such as unfavorable environmental protection requirements, secondary pollution of water quality, slow degradation of organic waste water, etc., and achieves improved biodegradability, fast degradation speed, and easy replacement of fillers. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

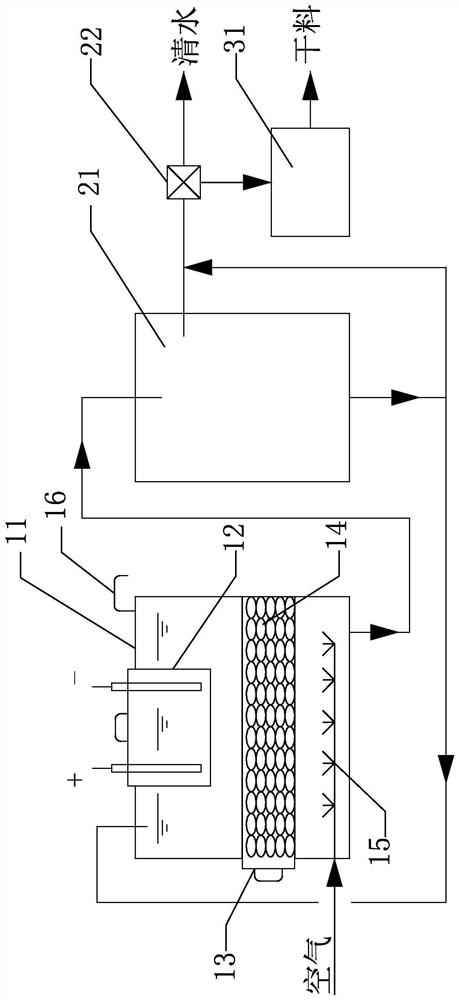

[0030] The present invention protects an iron-carbon micro-electrolysis coupled electrochemical water treatment device, which comprises an iron-carbon micro-electrolysis tank 11, a precipitation tank 21 and a drying box 31.

[0031] The upper layer of the iron-carbon micro-electrolyzer 11 is provided with an electrode box 12, the middle layer is provided with a drawer-type iron-carbon stuffing box 13, and the bottom layer is inserted with a porous aeration pipe 15.

[0032] The frame of the electrode box 12 is made of porous glass steel plate, and the anode and the cathode in the electrode box 12 are detachably fixed on the top plate of the electrode box 12 and can be drawn out for cleaning and replacement. The anode uses a titanium-based metal oxide electrode, and the cathode uses a graphite felt electrode.

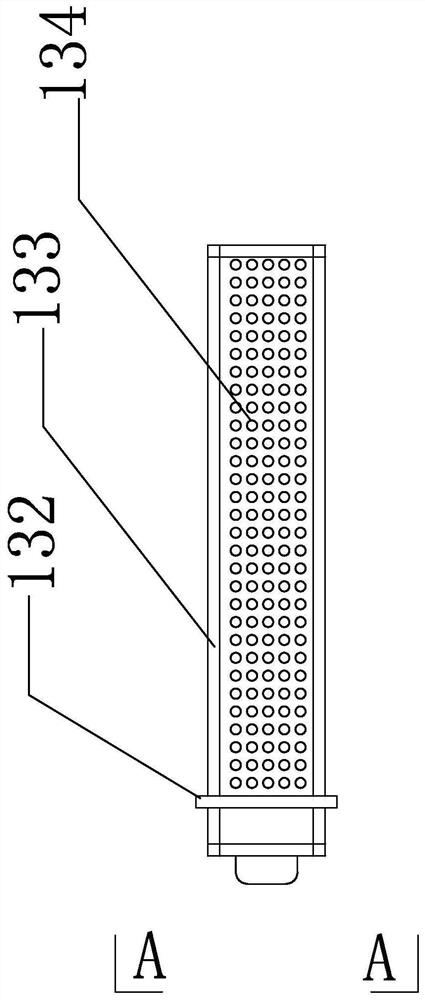

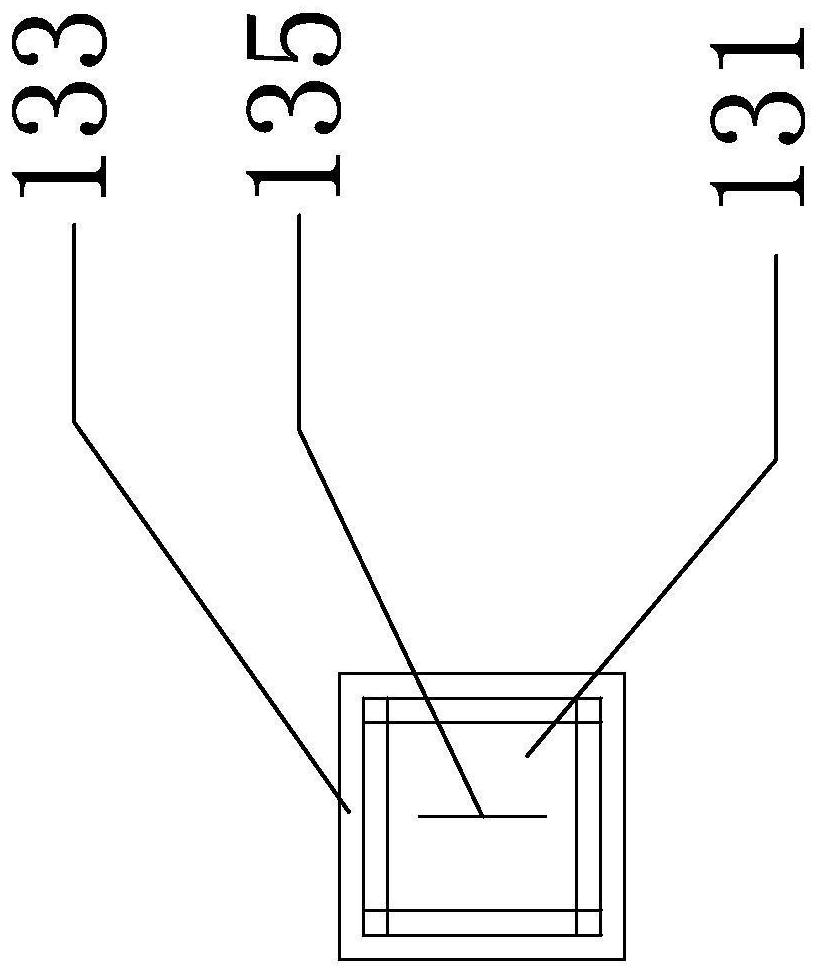

[0033] The drawer-type iron-carbon stuffing box 13 includes a connecting part and a receiving part. Combine figure 2 and image 3 As shown, the engaging portion includes an ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com