Preparation method of polysilicate metal salt-hollow porous silicon dioxide composite flocculant used for water treatment

A technology of porous silica and polysilicate metal salt, applied in water/sewage treatment, chemical instruments and methods, water/sludge/sewage treatment, etc. Good, limited adsorption, etc., to achieve the effect of enhancing the adsorption bridging effect, facilitating the precipitation of flocs, and improving the quality of effluent water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

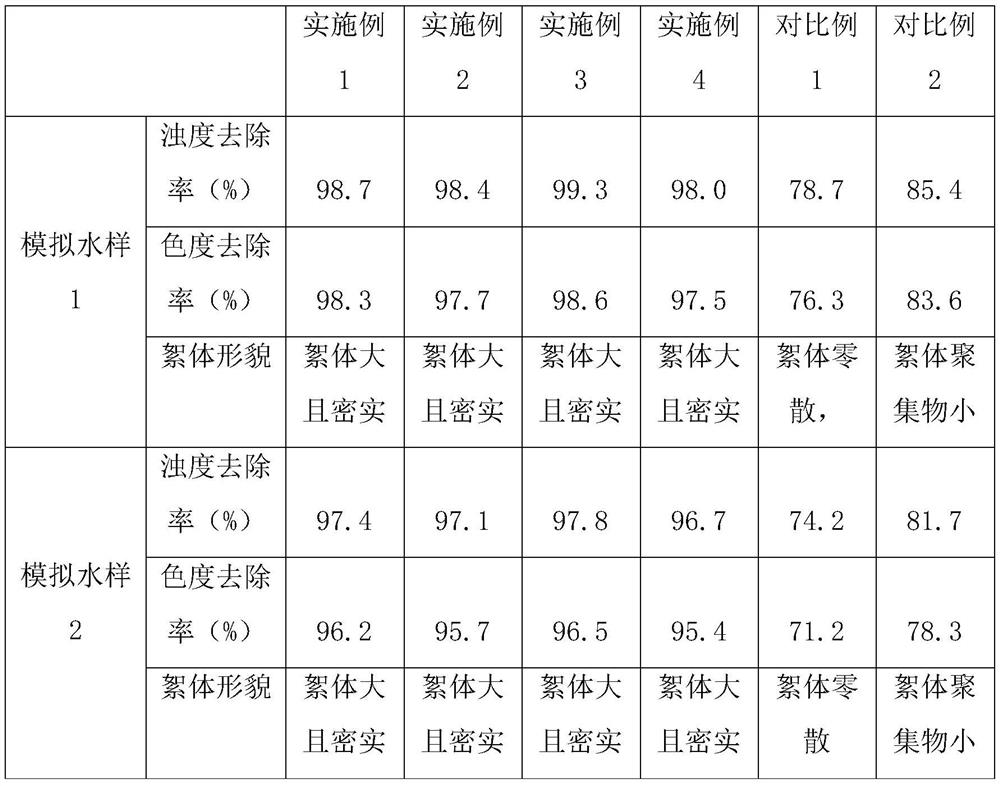

Examples

Embodiment 1

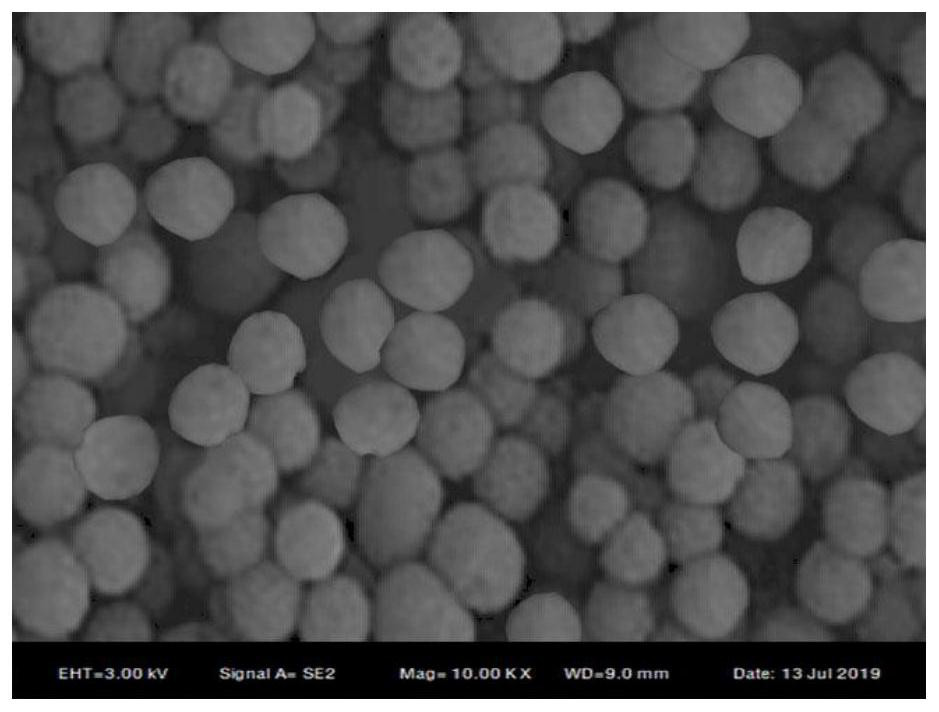

[0028] The preparation method of hollow porous silica composite microsphere comprises the following steps:

[0029] a) Mix ethylene glycol and distilled water in a ratio of 1:1 to obtain a mixed solution, add sodium hydroxide and cetyltrimethylammonium bromide to the mixed solution, sodium hydroxide, cetyltrimethylammonium The mass ratio of ammonium bromide and the mixed solution is 0.2:1:20, heat in a water bath to 75°C, then add tetraethyl orthosilicate, tetraethyl orthosilicate and hexadecyltrimethylammonium bromide The mass ratio is 1:0.2, stirred and reacted for 7 hours, centrifuged, washed, and dried to obtain a hollow porous silica matrix, and the hollow porous silica matrix was calcined at 650°C for 3 hours in a muffle furnace to obtain a hollow porous silica;

[0030] b) Add salicylic acid and epichlorohydrin to 1,2-dichloroethane solvent, the mass ratio of salicylic acid to epichlorohydrin is 1:1.5, salicylic acid and 1,2-dichloroethane The mass ratio is 1:30, the ...

Embodiment 2

[0037] The preparation method of hollow porous silica composite microsphere comprises the following steps:

[0038] a) Mix ethylene glycol and distilled water in a ratio of 1:1 to obtain a mixed solution, add sodium hydroxide and cetyltrimethylammonium bromide to the mixed solution, sodium hydroxide, cetyltrimethylammonium The mass ratio of ammonium bromide and the mixed solution is 0.2:1:20, heat it in a water bath to 65°C, then add tetraethyl orthosilicate, tetraethyl orthosilicate and hexadecyltrimethylammonium bromide The mass ratio is 1:0.5, stirred and reacted for 5 hours, centrifuged, washed, and dried to obtain a hollow porous silica matrix, and the hollow porous silica matrix was placed in a muffle furnace and calcined at 600°C for 6 hours to obtain a hollow porous silica matrix. silica;

[0039] b) Add salicylic acid and epichlorohydrin to 1,2-dichloroethane solvent, the mass ratio of salicylic acid to epichlorohydrin is 1:1.5, salicylic acid and 1,2-dichloroethane ...

Embodiment 3

[0046] The preparation method of hollow porous silica composite microsphere comprises the following steps:

[0047] a) Mix ethylene glycol and distilled water in a ratio of 1:1 to obtain a mixed solution, add sodium hydroxide and cetyltrimethylammonium bromide to the mixed solution, sodium hydroxide, cetyltrimethylammonium The mass ratio of ammonium bromide and the mixed solution is 0.2:1:20, heat it in a water bath to 70°C, then add tetraethyl orthosilicate, tetraethyl orthosilicate and hexadecyltrimethylammonium bromide The mass ratio is 1:0.3, stirred and reacted for 8 hours, centrifuged, washed, and dried to obtain a hollow porous silica matrix. The hollow porous silica matrix was placed in a muffle furnace and calcined at 630°C for 5 hours to obtain a hollow porous silica matrix. silica;

[0048] b) Add salicylic acid and epichlorohydrin to 1,2-dichloroethane solvent, the mass ratio of salicylic acid to epichlorohydrin is 1:2, salicylic acid and 1,2-dichloroethane The m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com