Method for producing masonry material by utilizing foamed ceramic waste

A technology of foamed ceramics and foamed ceramic plates, which is applied in the field of solid waste recycling, can solve problems such as secondary pollution, insufficient combination of foamed ceramic production processes, and general sound insulation performance, and achieve the effect of improving sound insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The foamed ceramic waste used in all the embodiments of the present invention is the waste produced by the applicant (Jinyi Lvneng New Materials) foamed ceramic plate production line, including unqualified waste and cutting and polishing in the production process of foamed ceramics crumbs.

[0035] The foamed ceramic waste is crushed with a crusher, and then the crushed material is screened to obtain granular waste and powdery waste, wherein the particle size of the granular waste is 1mm-30mm, and the particle size of the powdery powder is <1mm .

[0036] Weigh 325 cement, granular waste and powdery waste according to the following mass percentages: 50% of 325 cement, 20% of granular waste, and 30% of powdery waste, add water and mix uniformly to make a slurry.

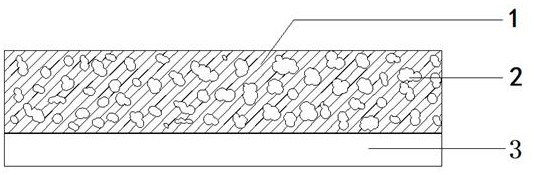

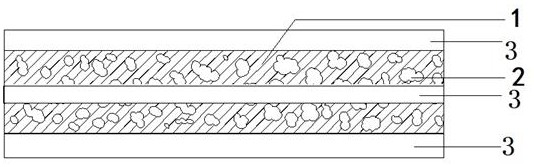

[0037] Select a foamed ceramic plate with a specification of 2000mm*1000mm*20mm, set a surrounding edge with a height of 60mm around it, then pour the slurry, shake and smooth it, and maintain it in a humid en...

comparative example 1-1

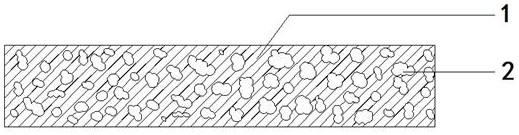

[0039] The slurry is prepared according to the proportioning process in Example 1, and the above slurry is poured into a conventional mold for vibration and compaction to obtain a masonry material product of the desired shape. In this example, we made a plate with a specification of 2000mm*1000mm*80mm, and maintained the plate in a humid environment for at least 15 days to obtain a plate-shaped material that can be used for wall masonry. Its cross-sectional structure is shown in the attached figure 2 As shown, granular foamed ceramic waste 2 is wrapped in concrete 1 . We tested the board, and the air sound insulation is 38dB. In terms of this thickness, the sound insulation performance of the material is average.

Embodiment 2

[0046] Under the condition that the ratio of raw materials is determined, the particle size of granular waste is related to the compressive strength and air insulation volume of masonry materials. We test this. Select the following mass ratio: 325 cement 40%; granular waste 20%, powdery waste 40%.

[0047] 2-1. The particle size of granular waste is 5mm-10mm.

[0048] 2-2. The particle size of granular waste is 10mm-15mm.

[0049] 2-3, The particle size of granular waste is 15mm-20mm.

[0050] 2-4, the particle size of granular waste is 20mm-25mm.

[0051] 2-5, the particle size of granular waste is 25mm-30mm.

[0052] Other processes, such as embodiment 1, are prepared into a masonry material with a thickness of 80mm, and the sound insulation performance of the test is as follows:

[0053] 2-1: The air insulation volume is 47dB.

[0054] 2-2: The air insulation volume is 49dB.

[0055] 2-3: Air insulation volume 50dB.

[0056] 2-4: Air insulation volume is 45dB.

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com