A method for extracting metals from soot

A technology for extracting metals and soot, applied to alkali metal compounds, alkali metal chlorides, chemical instruments and methods, etc., can solve problems such as difficult processing, large differences, complex composition, etc., achieve good technology application prospects, and reduce production costs , significant economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

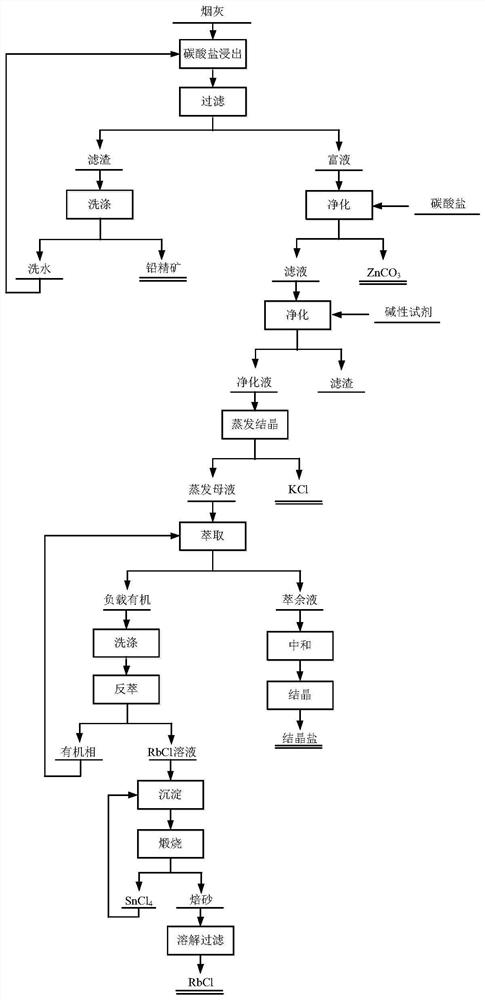

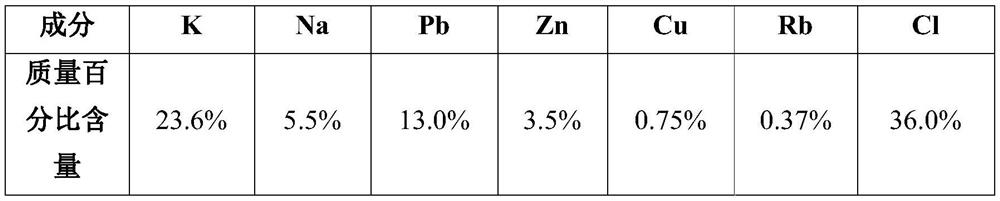

[0041] use figure 1 The process shown is for the extraction of metals from soot and the processing of smelting soot. Specifically: Take 500g of heavy metal industrial sludge smelting soot, and its component analysis is shown in Table 1.

[0042] Table 1

[0043]

[0044] Processing includes the following steps:

[0045] Add 40g K to the soot 2 CO 3 , add 1500ml of water to carry out leaching at room temperature, react for 3h and then filter to obtain 1356ml of lead-containing filter residue and metal-rich solution. Measure 500ml of water to wash the lead-containing filter residue, wash twice, and obtain 135g of lead concentrate after filtering.

[0046] Add 20g K to the metal-rich solution 2 CO 3 and 8g Na 2 CO 3 carry out the reaction, then filter to obtain the filter residue, and use 100ml water to wash the filter residue to obtain ZnCO 3 Product 26.4g. Then add 5g NaOH and 7g K to the filtrate 2 CO 3 , adjust the pH to 11, filter again to obtain 1319ml of pu...

Embodiment 2

[0057] use figure 1 The process shown is for the extraction of metals from soot and the processing of smelting soot. Specifically: Take 500g of heavy metal industrial sludge smelting soot, and its component analysis is shown in Table 1.

[0058] Processing includes the following steps:

[0059] Add 30g K to the soot 2 CO 3 and 8g KHCO 3 , add 1300ml of water for leaching at 50°C, react for 2 hours and then filter to obtain 1176ml of lead-containing filter residue and metal-rich solution. Measure 400ml of water to wash the lead-containing filter residue for 3 times, and obtain 132g of lead concentrate after filtering.

[0060] Add 25g K to the metal-rich solution 2 CO 3 , filtered to obtain the filtrate and filter residue, and the precipitated residue was washed with 100ml of water to obtain ZnCO 3 Product 21.4g. Then add 6g KOH and 6g NaOH to the filtrate, adjust the pH to 12, filter again to obtain 1143ml of purified solution, the quality of purified solution is 1321...

Embodiment 3

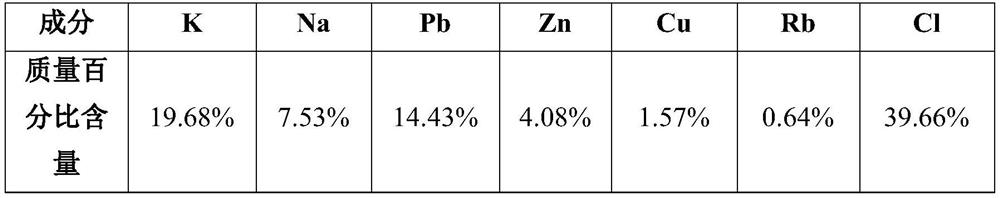

[0071] use figure 1 The process shown is for the extraction of metals from soot and the processing of smelting soot. Specifically: Take 500g of heavy metal industrial sludge smelting soot, and its component analysis is shown in Table 2.

[0072] Table 2

[0073]

[0074] Processing includes the following steps:

[0075] Add 30g K to the soot 2 CO 3 and 15g KHCO 3, add 1200ml of water for leaching at 70°C, react for 1.5h and then filter to obtain 1037ml of lead-containing filter residue and metal-rich solution. Measure 400ml of water to wash the lead-containing filter residue, wash twice, and obtain 147.3g of lead concentrate after filtering.

[0076] Add 30g K to the metal-rich solution 2 CO 3 and 10g Na 2 CO 3 , filtered to obtain the filtrate and filter residue, and the precipitated residue was washed with 100ml of water to obtain ZnCO 3 Product 35.1 g. Then add 9g of KOH to the filtrate, adjust the pH to 10, and filter again to obtain 1017ml of purified solut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com