BiOI/MoS2 heterojunction composite photocatalyst as well as preparation method and application thereof

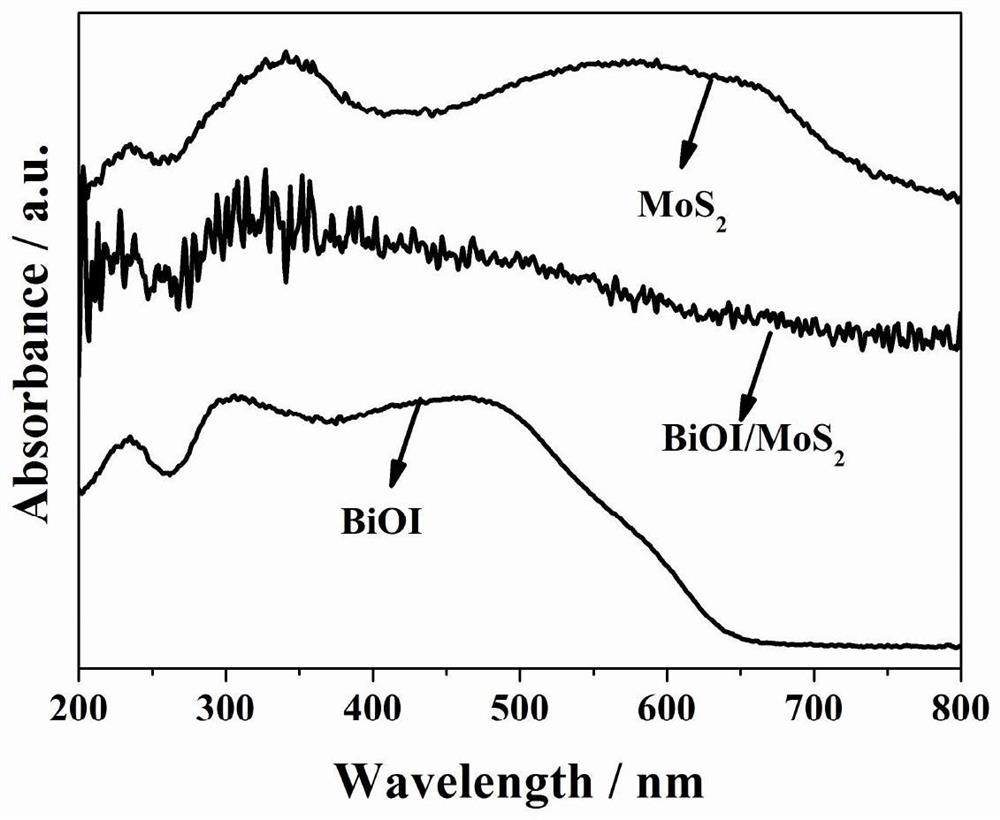

A technology of composite light and catalyst, applied in the field of photocatalysis, can solve the problems that hinder the development of BiOI materials, achieve good visible light absorption performance and photocatalytic performance, improve visible light catalytic activity, and have good practical value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

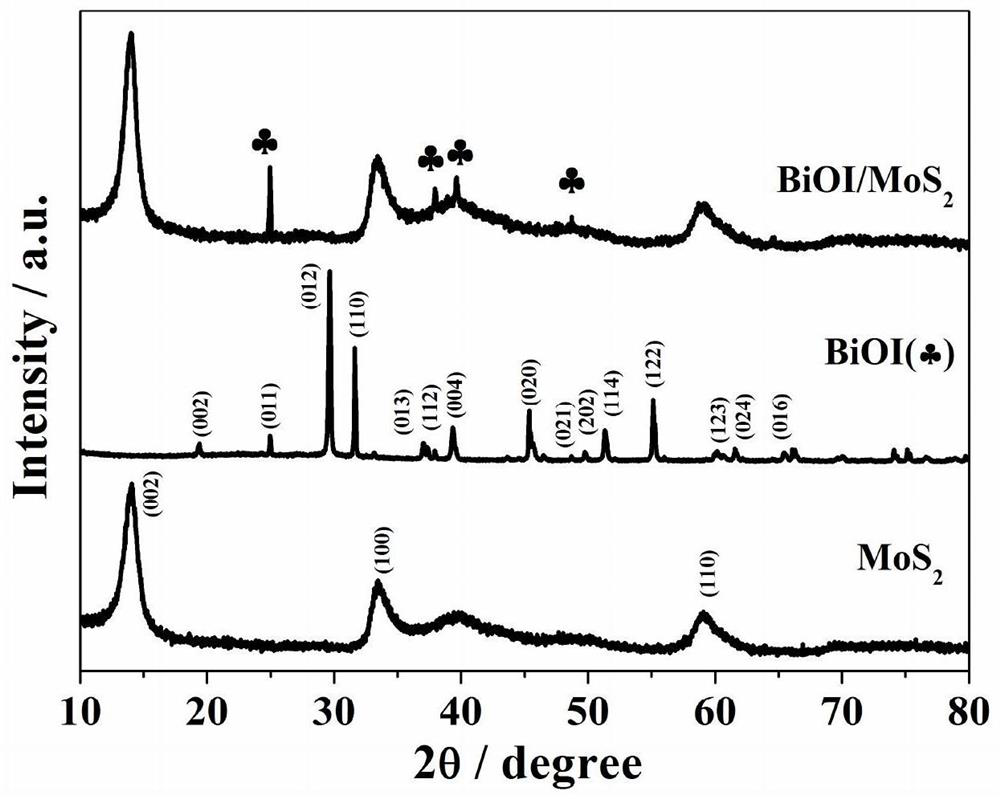

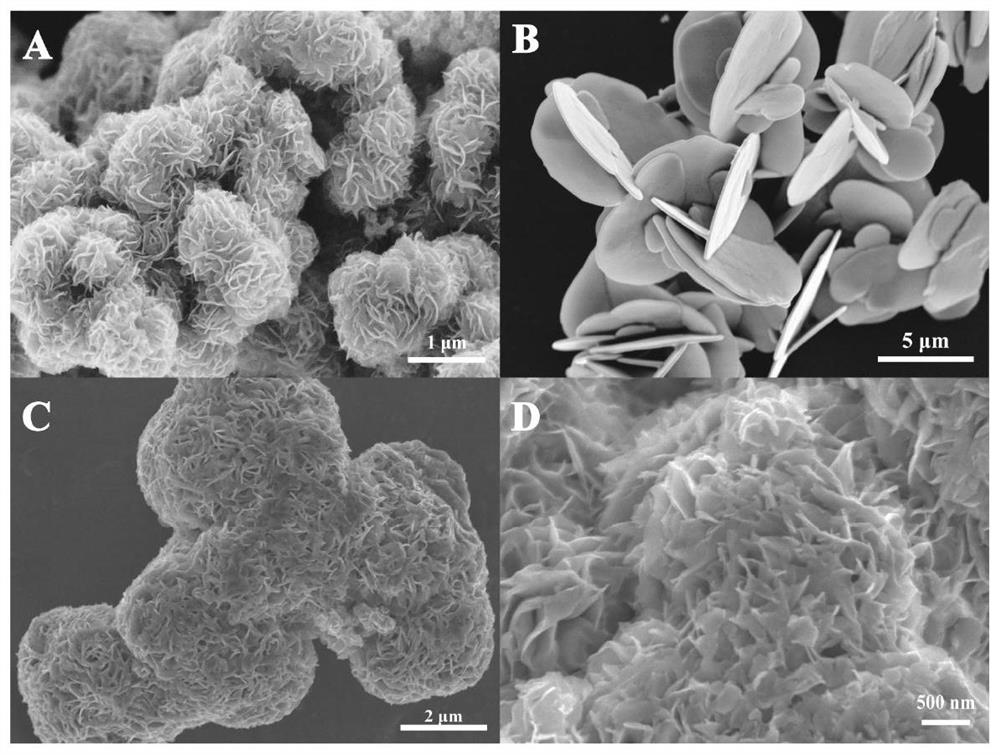

[0032] Example 1 BiOI / MoS 2 Preparation of Heterojunction Composite Photocatalyst

[0033] (1)MoS 2 Preparation: add 1mmol (NH 4 ) 6 Mo 7 o 24 ·5H 2 O and 20 mmol CH 4 N 2 S, stirred and dissolved, transferred to a 100mL polytetrafluoroethylene reactor, reacted at 200°C for 20h, cooled to room temperature, filtered to collect the precipitate, washed several times with deionized water and ethanol, and then heated at 60°C Dry under normal pressure to obtain MoS 2 sample.

[0034] (2)BiOI / MoS 2 Preparation of heterojunction composite photocatalyst: 0.16g MoS 2 , 0.1mmol Bi(NO 3 ) 3 ·5H 2 O and 1g of PVP were dissolved in 30mL of ethylene glycol and ultrasonicated for 6h to form solution A; 0.3mmol KI was dissolved in 10mL of ultrapure water to form solution B. Add solution B dropwise to solution A under stirring, continue to stir for 30min after the dropwise addition is completed, transfer to a 50mL polytetrafluoroethylene reactor, react at 180°C for 48h, cool to roo...

Embodiment 2

[0040] Example 2 BiOI / MoS 2 Preparation of Heterojunction Composite Photocatalyst

[0041] 1) The difference from Example 1 is that the control (NH 4 ) 6 Mo 7 o 24 ·5H 2 O and CH 4 N 2 The molar ratio of S is 1:30. Add 1 mmol (NH 4 ) 6 Mo 7 o 24 ·5H 2 O and 30 mmol CH 4 N 2 S, stirred and dissolved, transferred to a 100mL polytetrafluoroethylene reactor, reacted at 200°C for 20h, cooled to room temperature, filtered to collect the precipitate, washed several times with deionized water and ethanol, and kept at 60°C after washing Dry under high pressure to obtain MoS 2 sample.

[0042] 2) Then 0.16g MoS 2 , 0.1mmol Bi(NO 3 ) 3 ·5H 2 O and 1g of PVP were dissolved in 30mL of ethylene glycol, sonicated for 6h to form solution A; 0.3mmol KI was dissolved in 10mL of ultrapure water, ultrasonically dispersed for 6h to form solution B. Add solution B dropwise to solution A under stirring, then continue to stir for 30 minutes, transfer to a 50mL polytetrafluoroethy...

Embodiment 3

[0043] Example 3 BiOI / MoS 2 Preparation of Heterojunction Composite Photocatalyst

[0044] The difference from Example 1 is that the control of MoS 2 Ultrasonic time is 4h. Add 1 mmol (NH 4 ) 6 Mo 7 o 24 ·5H 2 O and 20 mmol CH 4 N 2 S, stirred and dissolved, transferred to a 100mL polytetrafluoroethylene reactor, reacted at 200°C for 20h, cooled to room temperature, filtered to collect the precipitate, washed with deionized water and ethanol, and then heated at 60°C under normal pressure Drying under , to get MoS 2 sample. Then 0.16g MoS 2 , 0.1mmol Bi(NO 3 ) 3 ·5H 2 O and 1g of PVP were dissolved in 30mL of ethylene glycol and ultrasonicated for 4h to form solution A; 0.3mmol was dissolved in 10mL of ethanol to form solution B. Add solution B dropwise to solution A under stirring, then stir for 30min, transfer to a 50mL polytetrafluoroethylene reactor, react at 180°C for 48h, cool to room temperature, collect the precipitate by filtration, and use Washed with ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com