Electrified railway traction emergency guarantee power supply system and control method

A technology for traction power supply systems and electrified railways. It is applied in power lines, photovoltaic power generation, transportation and packaging, etc. It can solve the problems of short power supply time of on-board emergency power supplies, failure to take power normally, and high requirements for forward transmission capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] In order to make the purpose, technical solution and advantages of the present invention clearer, the present invention will be further elaborated below in conjunction with the accompanying drawings.

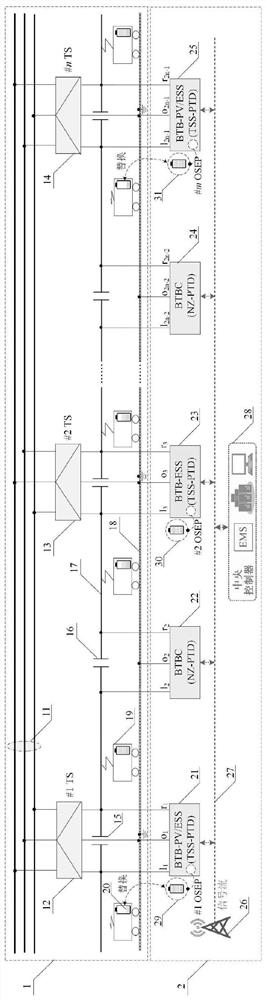

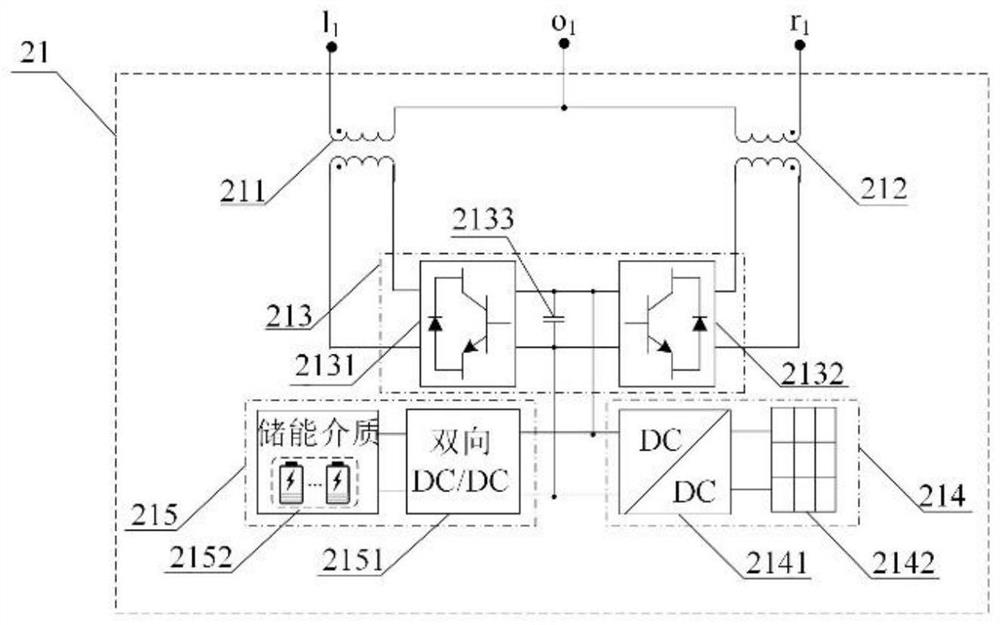

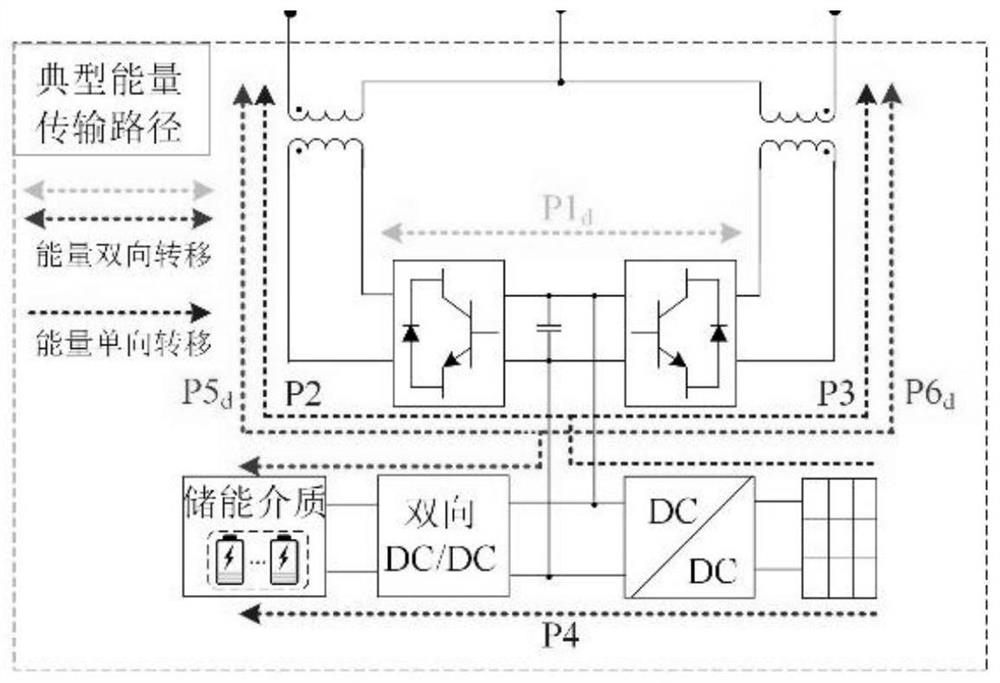

[0052] In this example, see figure 1 As shown, the present invention proposes an electrified railway traction emergency guarantee power supply system, including a phase-splitting traction power supply system 1 and an energy routing conversion system 2;

[0053] The phase-splitting traction power supply system 1 includes multi-stage traction transformer substations TS12.13.14; each traction transformer substation TS adopts a phase-sequence rotation method. The independent power supply arm 17 divided by 15 sub-phases of the transformer substation is connected to supply energy for the traction load; the traction load is a train 19 with a vehicle-mounted emergency power supply 20; a partitioned sub-phase substation is set between adjacent traction transformer substations TS ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com