Automatic boxing machine for articles on production line

A technology for packing machines and production lines, which is applied to packaging, conveyors, single objects, etc., and can solve problems such as complex control, limited scope of application, and low work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

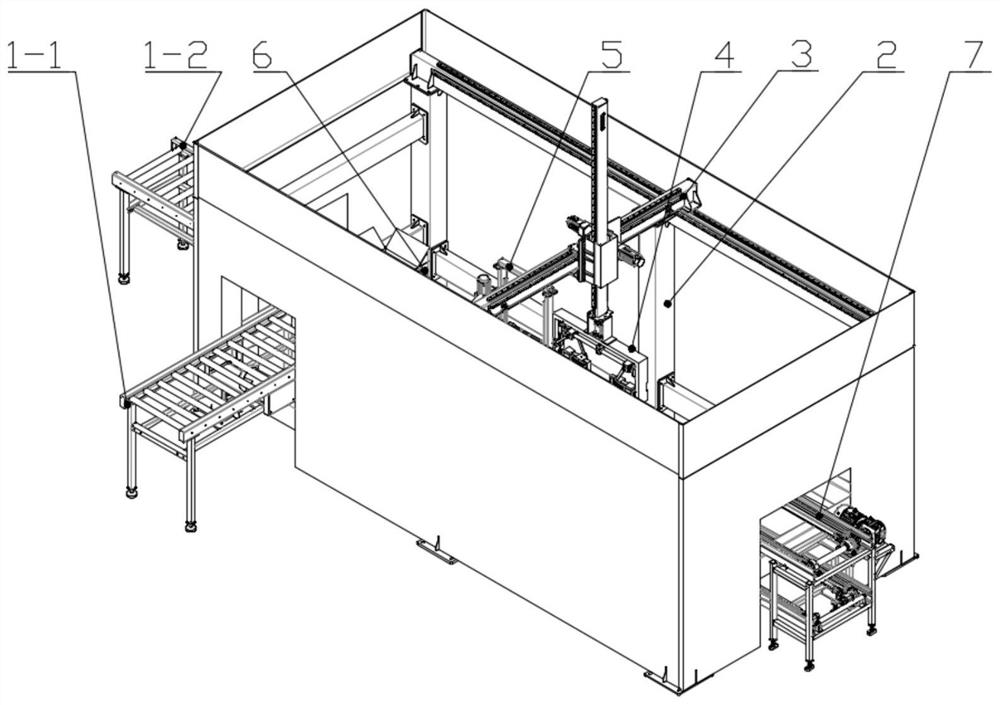

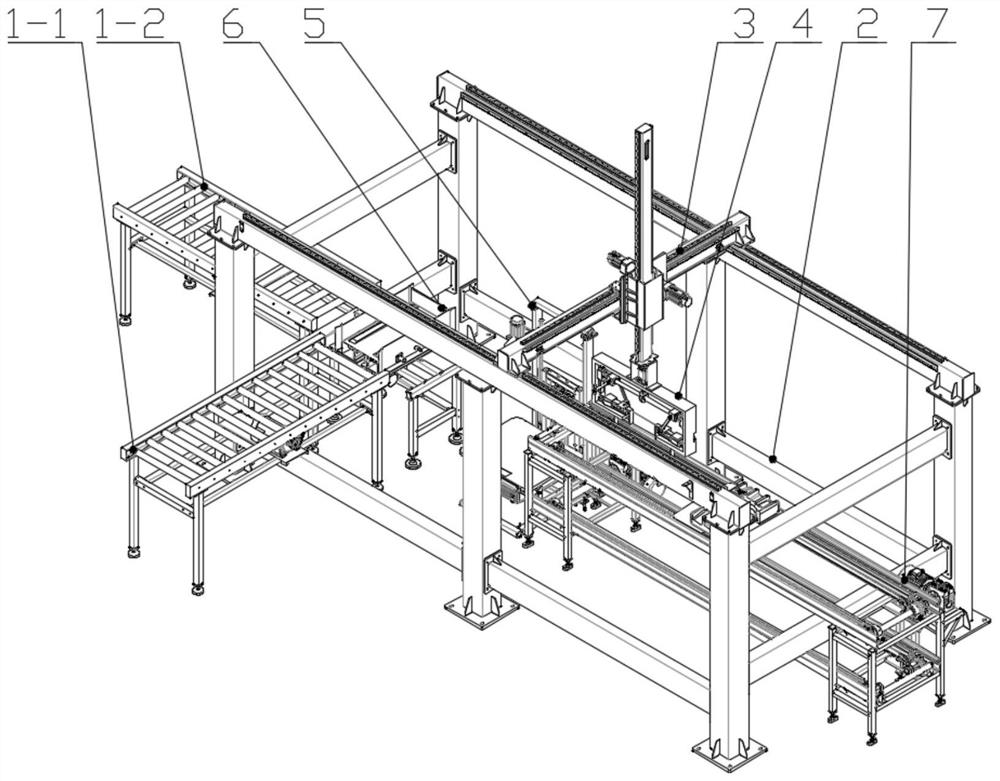

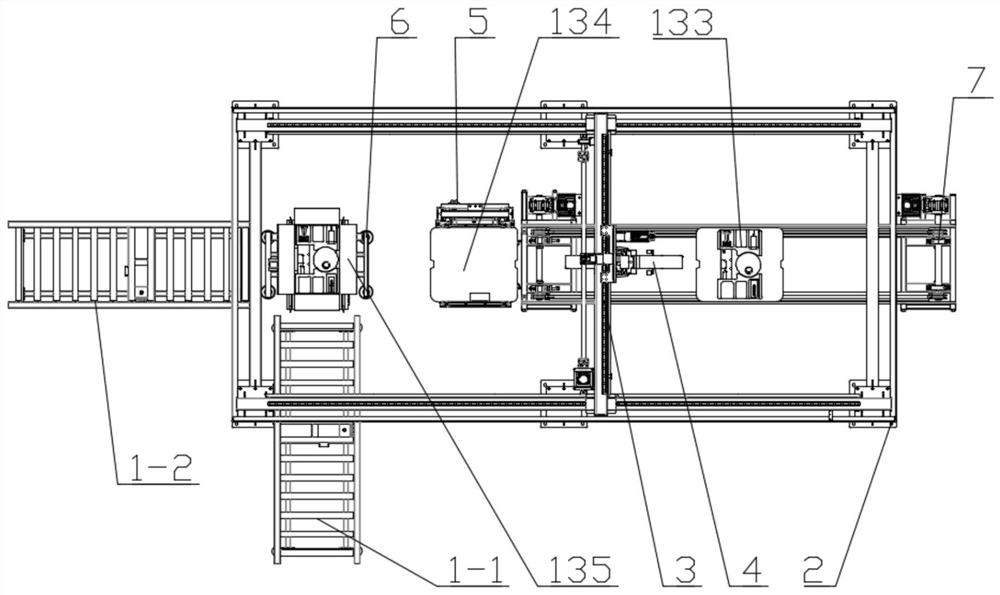

[0050] Embodiment 1: as Figure 1-27 As shown, an automatic packing machine for items in a production line, including packing case input roller line I1-1, product output roller line II1-2, equipment frame 2, three-degree-of-freedom mounting frame 3, packing manipulator 4, pallet changer Orientation device 5, packing case positioning and steering device 6, circular double speed chain 7; packing case input roller line Ⅰ1-1 is used to input packing case 135 to packing case positioning and steering device 6; product output roller line Ⅱ1-2 is used for The packaged items are output after the box is positioned and turned into the steering device 6; the equipment frame 2 is used to fix the three-degree-of-freedom mounting frame 3; the three-degree-of-freedom mounting frame 3 is used to drive the packing manipulator 4 installed on it to carry out six directions linear motion; the packing manipulator 4 is used to grab the item 133 to be packed on the circular double-speed chain 7, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com