Continuous hydrogenation production device and method for carbon-carbon double bonds in conjugated diene polymer

A conjugated diene, polymer technology, applied in chemical instruments and methods, organic compound/hydride/coordination complex catalysts, ruthenium organic compounds, etc., can solve the problem of high warehouse costs, building and operation management costs, large Working capital, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

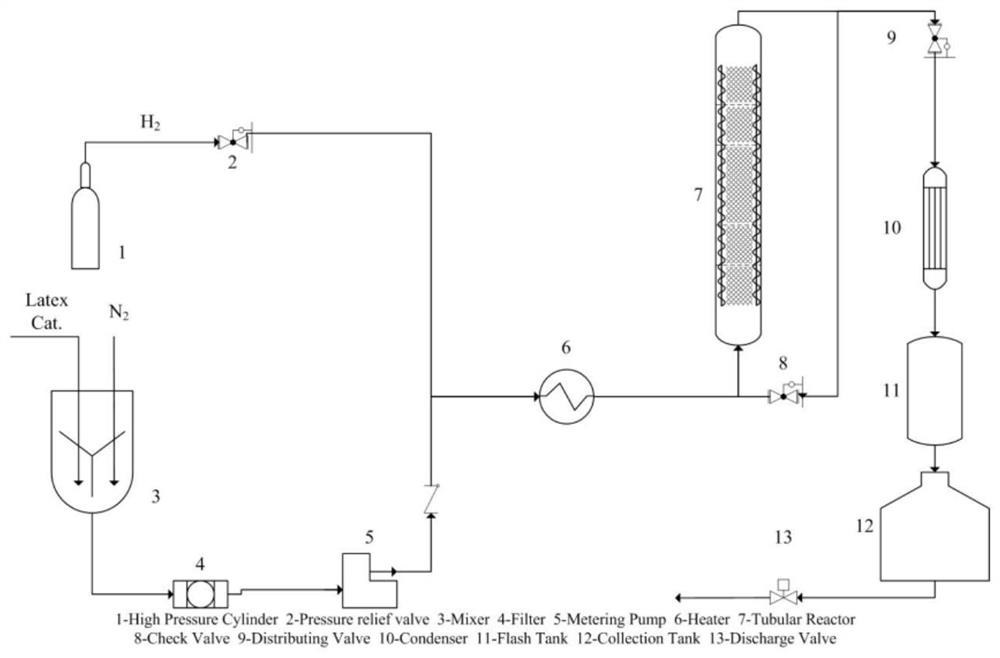

Method used

Image

Examples

preparation example Construction

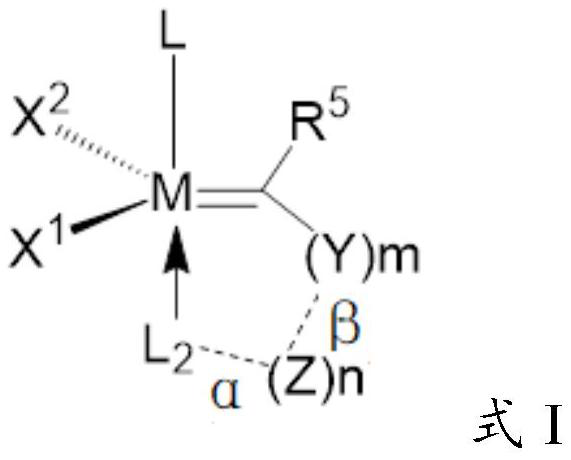

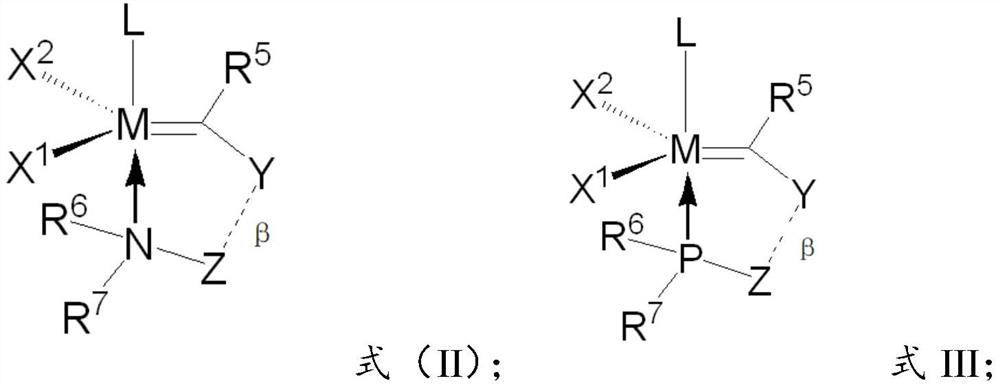

[0151] The preparation method of the catalyst for catalytic hydrogenation of conjugated diene latex is characterized in that it comprises the following steps:

[0152] In the Shrek system, an inert gas atmosphere is used to mix the Grubbs catalyst and the ligand. The molar mass ratio of the Grubbs catalyst to the ligand is 1:1-1:20, and the Grubbs catalyst is Grubbs Ⅱ catalyst or Grubbs Ⅲ catalyst, add organic solvent, react at 20-80°C for 0.1-24h or 4-10d, the reaction condition is reflux reaction or stirring reaction, under vacuum condition, remove the organic solvent , collected the solid, washed, and dried in vacuo to obtain the catalyst.

[0153] The mass percentage of the catalyst in the present invention in the polymer in the conjugated diene latex is 0.0001% to 5wt%; preferably 0.001wt% to 4wt%; more preferably 0.01wt% to 3wt%; most preferably 0.01wt% %~0.5wt%.

[0154] The auxiliary agent is selected from one or more of linear (alkene) acid salts, linear alkyl sulfa...

Embodiment 1-1

[0166] A preparation method of a catalyst for catalytic hydrogenation of conjugated diene latex of the present invention comprises the following steps: in the Shrek system, using a nitrogen gas atmosphere, 0.1 mmol of the Grubbs II catalyst and a ligand 2-(3 -Butene)pyridine 0.2mmol mixed, add organic solvent dichloromethane 15mL, at 20 ℃, heat reflux 4h, under vacuum condition, remove organic solvent dichloromethane, collect solid, adopt hexane to wash, wash three times, each time The amount of hexane was 5 mL, and it was dried under vacuum to obtain a light green solid, which was designated as catalyst IVa.

[0167] After measuring, this catalyst IVa is 0.063mmol, and yield is 63%, and its structural formula is as follows:

[0168]

Embodiment 1-2

[0170] A preparation method of a catalyst for catalytic hydrogenation of conjugated diene latex of the present invention comprises the following steps: in the Shrek system, using an argon gas atmosphere, 0.1 mmol of the Grubbs II catalyst and a ligand 2-( 3-butene) pyridine 1.4mmol mixed, add organic solvent dichloromethane 15mL, at 80 ℃, heat reflux 24h, under vacuum condition, remove organic solvent dichloromethane, collect solid, adopt hexane to wash, wash three times, every The amount of hexane was 5 mL, and it was vacuum-dried to obtain a light green solid, which was designated as catalyst IVa.

[0171] After measuring, this catalyst IVa is 0.080mmol, and yield is 80%, and its structural formula is as follows:

[0172]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com