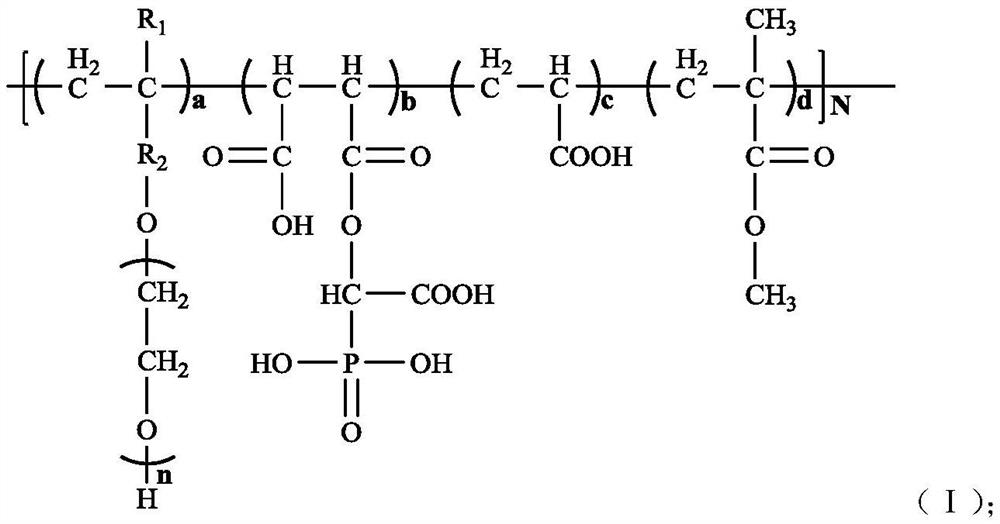

Mud-resistant and slump-retaining polycarboxylate superplasticizer and preparation method thereof

A technology of slump-preserving polycarboxylate, which is applied in the field of slump-preserving polycarboxylate water reducer and its preparation, and anti-mud, which can solve the problem of increasing loss of slump and expansion over time, increasing production and operation costs, Abnormal coagulation time and other problems can be achieved to improve the workability and mechanical properties, enhance the competitive adsorption capacity, and improve the complexation ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

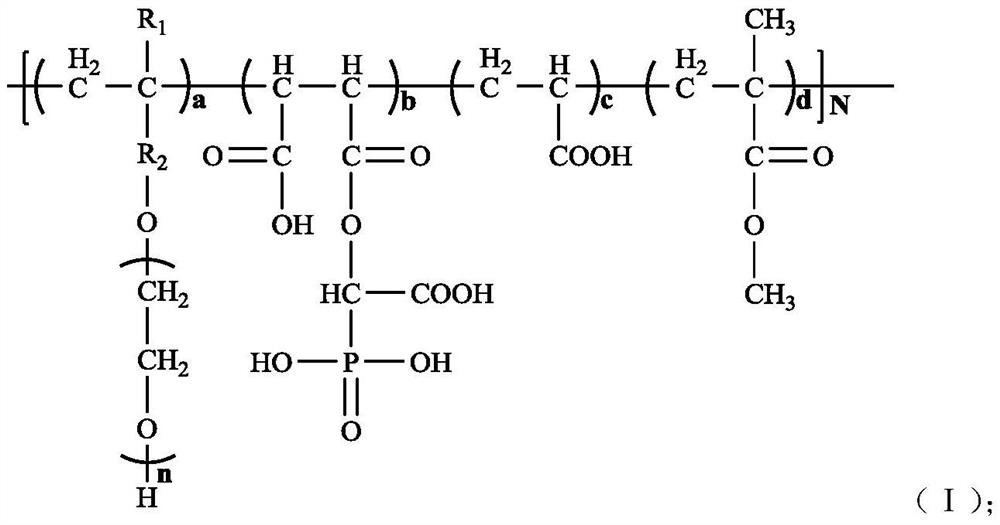

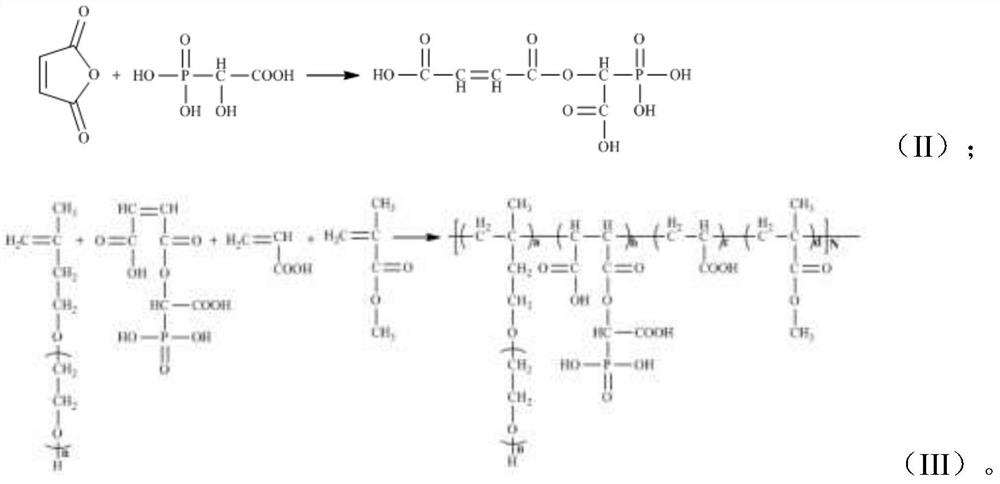

[0033] A mud-resistant, slump-preserving polycarboxylate superplasticizer, its synthesis route is shown in formula II and formula III, and its preparation method includes the following steps:

[0034] Add 2.6 parts of MA and 4.1 parts of HPAA into a three-necked flask equipped with a thermometer, a stirrer and a reflux condenser, stir and react at 60°C for 2 hours (500r / min), after cooling to room temperature, add 27.4 parts of TPEG, 28.8 3 parts of water and 0.5 parts of APS, and react at 60°C until the TPEG macromonomer is completely dissolved, then start to add solution A (0.3 parts of TGA, 14.4 parts of water) and solution B (4.5 parts of AA, 2.8 parts of MMA, 12.3 parts of deionized water), control the dropping time for 3 hours, after the dropping, keep the temperature at 60°C for 1 hour, adjust the pH value of the reaction solution to 6-7 with 30wt% NaOH solution, and obtain the mud-resistant and slump-preserving polycarboxylate superplasticizer PCE-1 (relative molecular...

Embodiment 2

[0037] A mud-resistant, slump-preserving polycarboxylate water reducer, the preparation method of which comprises the following steps:

[0038] Add 2.6 parts of MA and 4.1 parts of HPAA into a three-necked flask equipped with a thermometer, a stirrer and a reflux condenser, stir and react at 60°C for 2 hours (500r / min), after cooling to room temperature, add 27.4 parts of HPEG, 28.8 parts into the three-necked flask part of water and 0.5 part of APS, and react at 60°C until the HPEG macromonomer is completely dissolved, start to add solution A (0.3 parts of TGA, 14.4 parts of water) and solution B (4.5 parts of AA, 2.8 parts of MMA, 12.3 parts of water) dropwise, and control Adding time is 3 hours. After the dropping, keep warm for 1 hour. Use 30% NaOH solution to adjust the pH value of the reaction solution to 6-7 to obtain mud-resistant and slump-preserving polycarboxylate superplasticizer PCE-2 (relative molecular weight 52648; 36.4% solids).

Embodiment 3

[0040] A mud-resistant, slump-preserving polycarboxylate water reducer, the preparation method of which comprises the following steps:

[0041]Add 3.0 parts of MA and 5.8 parts of HPAA into a three-necked flask equipped with a thermometer, a stirrer, and a reflux condenser, stir and react at 60°C for 2 hours (500r / min), and after cooling to room temperature, add 25.9 parts of TPEG, 27.1 part of water and 0.5 part of APS, reacted at 60°C until the TPEG macromonomer was completely dissolved, began to dropwise add solution A (0.4 parts of TGA, 13.6 parts of water) and solution B (3.1 parts of AA, 3.6 parts of MMA, 11.6 parts of water), and control Adding time is 3 hours. After the dropping, keep warm for 1 hour. Use 30% NaOH solution to adjust the pH value of the reaction solution to 6-7 to obtain mud-resistant and slump-preserving polycarboxylate superplasticizer PCE-3 (relative molecular weight 65711; 37.1% solids).

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com