A kind of super-concentrated liquid detergent and preparation method thereof

A liquid detergent, ultra-concentrated technology, applied in the field of daily chemistry, can solve the problems of poor fluidity, and achieve the effect of good water solubility, excellent decontamination performance, and strong electrolyte resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

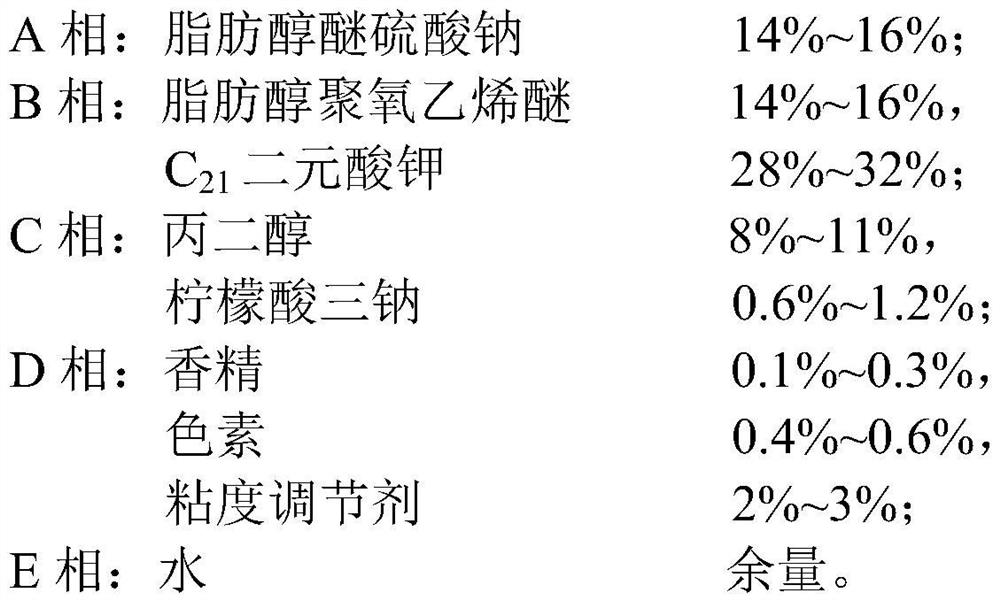

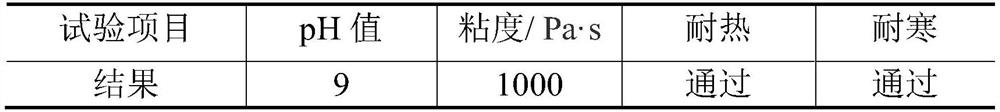

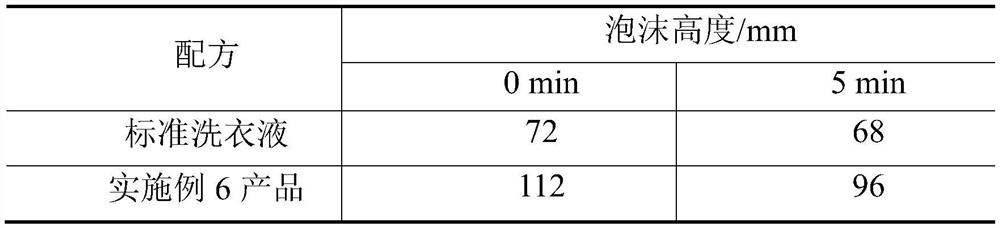

Method used

Image

Examples

Embodiment 1

[0020] An ultra-concentrated liquid detergent, comprising the following components by mass fraction: A phase: 16% fatty alcohol ether sodium sulfate; B phase: 16% fatty alcohol polyoxyethylene ether, C 21 Potassium dibasic acid 30%; phase C: propylene glycol 11%, trisodium citrate 1.2%; phase D: essence 0.3%, bright blue pigment 0.6%, viscosity modifier sodium chloride 3%; phase E: water balance.

[0021] A preparation method of super-concentrated liquid detergent, comprising the following steps:

[0022] (1) Raise the temperature to 85°C, add the material of phase A to the water of phase E at a rate of 1 drop per second, fully stir until completely dissolved, keep warm for 10 minutes, and stir to cool down;

[0023] (2) Cool down to 65°C, add phase B materials in sequence, and stir well until the solution is clear and transparent;

[0024] (3) Cool down to 40°C, add phase C in sequence, and stir evenly;

[0025] (4) After returning to room temperature, add phase D in sequen...

Embodiment 2

[0029] An ultra-concentrated liquid detergent, comprising the following components by mass fraction: A phase: 15% fatty alcohol ether sodium sulfate; B phase: 15% fatty alcohol polyoxyethylene ether, C 21 Dibasic acid potassium 29%; C phase: propylene glycol 10%, trisodium citrate 1.1%; D phase: essence 0.25%, lemon pigment 0.45%, viscosity regulator sodium chloride 2.5%; E phase: water balance.

[0030] A preparation method of super-concentrated liquid detergent, comprising the following steps:

[0031] (1) Raise the temperature to 90°C, add the material of phase A to the water of phase E at a rate of 1 drop per second, stir well until it is completely dissolved, keep it warm for 15 minutes, and stir to cool down;

[0032] (2) Cool down to 63°C, add phase B materials in sequence, and stir well until the solution is clear and transparent;

[0033] (3) Cool down to about 45°C, add phase C in sequence, and stir evenly;

[0034] (4) After returning to room temperature, add phas...

Embodiment 3

[0038] An ultra-concentrated liquid detergent, comprising the following components in terms of mass fraction: Phase A: fatty alcohol ether sodium sulfate 16%; Phase B: fatty alcohol polyoxyethylene ether 15%, C 21 Potassium dibasic acid 30%; phase C: propylene glycol 11%, trisodium citrate 1%; phase D: essence 0.2%, bright blue pigment 0.5%, viscosity regulator sodium chloride 2%; phase E: water balance.

[0039] A preparation method of super-concentrated liquid detergent, comprising the following steps:

[0040] (1) Raise the temperature to 87°C, add the material of phase A to the water of phase E at a rate of 1 drop per second, fully stir until completely dissolved, keep warm for 13 minutes, and stir to cool down;

[0041] (2) Cool down to 62°C, add phase B materials in sequence, and stir well until the solution is clear and transparent;

[0042] (3) Cool down to 42°C, add phase C in sequence, and stir evenly;

[0043] (4) After returning to room temperature, add phase D i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com