Effective and controllable preparation method of framework with multi-polar hole structure

A multi-pole hole and skeleton technology, which is applied in metal processing equipment, transportation and packaging, etc., can solve the problems of tungsten skeleton pore distribution, etc., and achieve the effects of low arc ablation rate, high withstand voltage strength and high mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] The present invention provides an effective and controllable method for preparing a skeleton with a multipolar porous structure, which is specifically implemented according to the following steps:

[0025] Step 1, first prepare spherical aggregate tungsten powder by flame spraying reduced tungsten powder, and prepare spherical tungsten powder with porous structure;

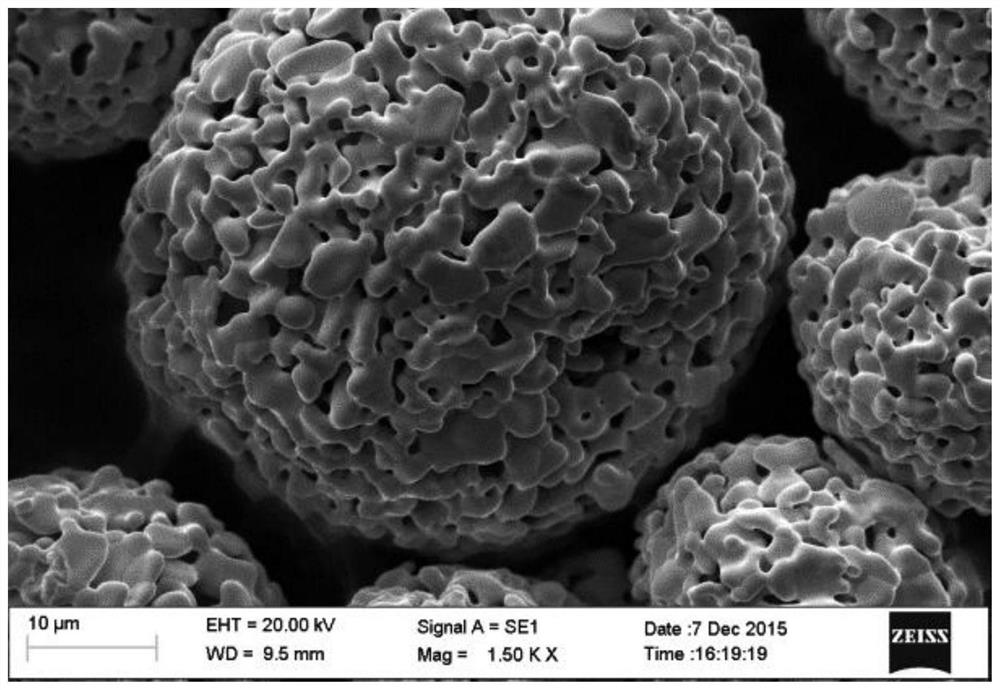

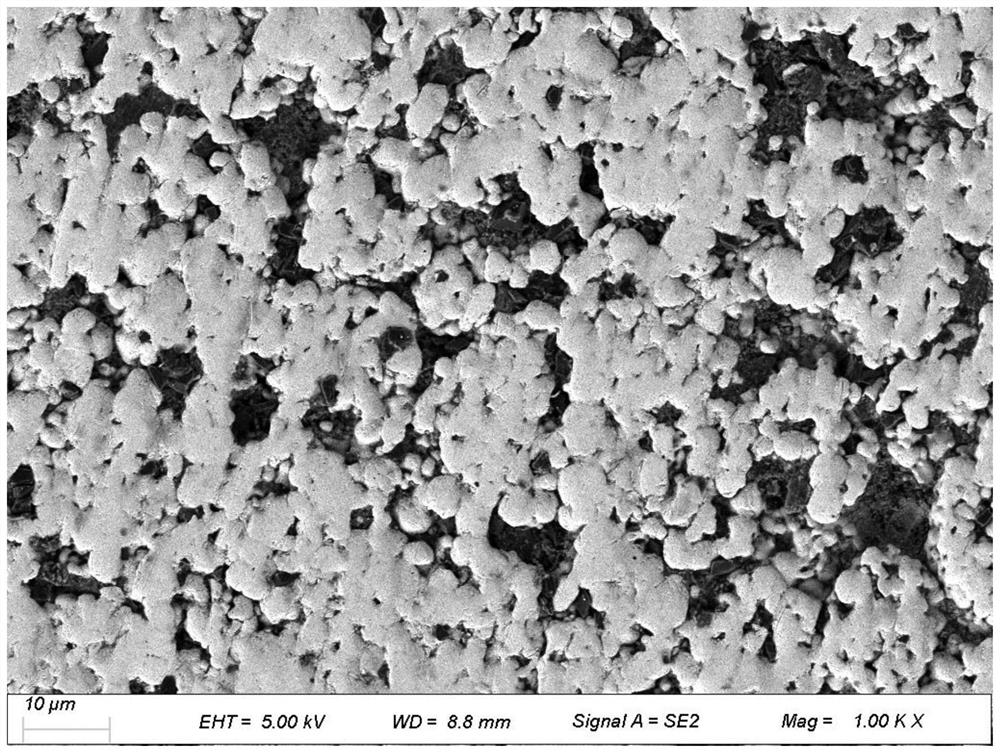

[0026] Among them, the scanning electron microscope (SEM) morphology of tungsten powder is as follows: figure 1 As shown, the initial powder presents a typical bimodal particle size distribution, that is, it is composed of two parts with a particle size of 15-40 μm and 40-63 μm; figure 1 It can be seen that spherical tungsten powder is made of a large number of unreduced tungsten powder agglomerates, and its shape is irregular, such as rods, rods, etc., and the particle size is different. Multiple particles gather together to form honeycomb through holes with developed surface area; It can be seen that the...

Embodiment 1

[0034] Step 1, firstly prepare spherical aggregate tungsten powder by flame spraying reduced tungsten powder, obtain spherical tungsten powder with a particle size of 15 μm, and the powder appearance is as follows figure 1 As shown, the content of Ct in tungsten powder is 0.16%-0.20%; the content of Ti is 0.0004%-0.0006%, the content of Al and Mn is 0.0440%-0.0460%; the content of O is 0.04%-0.06% %;

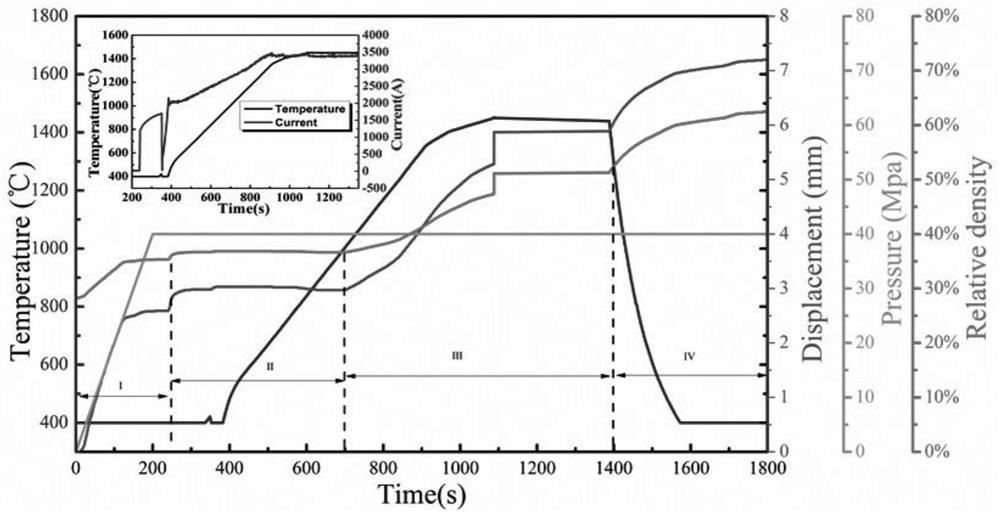

[0035] Step 2, using spark plasma sintering technology to prepare a tungsten skeleton with a multi-pole structure, and placing spherical tungsten powder with a particle size distribution of 15 μm in a graphite module with an inner diameter of 40 mm. The module is then loaded into the SPS device (Germany Raunstein FCT System Co., Ltd. HP D25); an axial pressure of 16Mpa is applied on the powder bed, and then increased to 40Mpa; after that, vacuum sintering is carried out at 1450°C with a heating rate of 100 ℃ min -1 and 50°C min -1 , the holding time is 5 minutes; in the cooli...

Embodiment 2

[0038] Step 1, firstly prepare spherical aggregate tungsten powder by flame spraying reduced tungsten powder, and obtain spherical tungsten powder with a particle size of 63 μm, the powder appearance is as follows figure 1 As shown, the content of Ct in tungsten powder is 0.16%-0.20%; the content of Ti is 0.0004%-0.0006%, the content of Al and Mn is 0.0440%-0.0460%; the content of O is 0.04%-0.06% %;

[0039]Step 2, using spark plasma sintering technology to prepare a tungsten skeleton with a multi-pole structure, and placing spherical tungsten powder with a particle size distribution of 63 μm in a graphite module with an inner diameter of 40 mm. The module was then loaded into the SPS device (HP D25, FCT Systems GmbH, Raunstein, Germany), and an axial pressure of 16Mpa was applied on the powder bed, and then increased to 40Mpa. Afterwards, vacuum sintering was carried out at 1500 °C with a heating rate of 100 °C min -1 and 50°C min -1 , the holding time is 5min; in the coo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com