Low-GI non deep-fried extruded instant noodles and making method thereof

A non-fried, instant noodle technology, applied in the field of food processing, can solve the problem of no research on non-fried instant noodles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

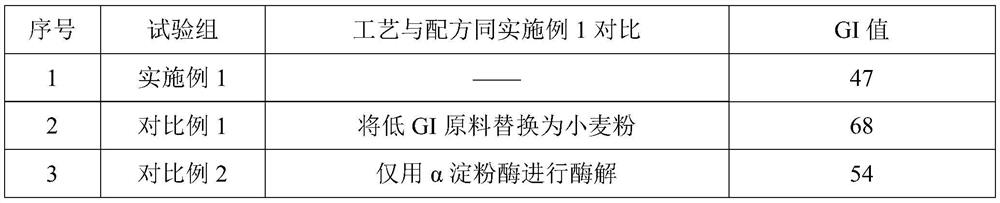

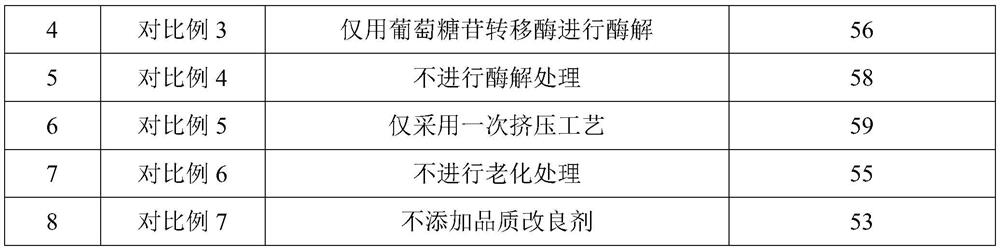

Examples

Embodiment 1

[0042] A low GI non-fried extruded instant noodle, comprising the following raw materials in parts by weight: 40 parts of wheat flour, 22 parts of whole wheat flour, 12 parts of high amylose corn starch, 3 parts of quinoa flour, 3 parts of buckwheat flour, 0.2 part of vegetable oil, fine konjac powder 0.2 parts, Artemisia gum 0.1 part, monoglyceride 0.01 part, resistant starch 2 parts, β-amylase 0.0001 (its enzyme activity is 65U / mL), glucosidase transferase 0.0001 (its enzyme activity is 3000U / mL ), 30 parts of purified water.

[0043] The preparation method of this low GI non-fried extruded instant noodles comprises the following steps:

[0044] S1. Enzymatic hydrolysis: Take 25 parts of wheat flour, pour it into an enzymatic hydrolysis tank, add pure water, stir to form a uniform paste, add β-amylase and glucosidyl transferase, heat up to 40°C, and enzymolyze for 4 hours to obtain a paste mixture raw material. The slow-digestible starch content of the pasty mixed raw mate...

Embodiment 2

[0056] A low GI non-fried extruded instant noodle, comprising the following raw materials in parts by weight: 50 parts of wheat flour, 25 parts of whole wheat flour, 15 parts of high amylose cornstarch, 5 parts of quinoa flour, 5 parts of buckwheat flour, 0.4 part of vegetable oil, fine konjac powder 0.4 parts, 0.2 parts of artemisia gum, 0.05 parts of monoglycerides, 3 parts of resistant starch, 0.00015 parts of β-amylase (the enzyme activity is 65U / mL), 0.00015 parts of glucosidase (the enzyme activity is 3000U / mL) mL), 40 parts of purified water.

[0057] The preparation method of this low GI non-fried extruded instant noodles comprises the following steps:

[0058] S1. Enzymatic hydrolysis: Take 30 parts of wheat flour, pour it into an enzymatic hydrolysis tank, add purified water, stir to form a uniform paste, add β-amylase and glucosidyl transferase, heat up to 45°C, and perform enzymatic hydrolysis for 3 hours to obtain a paste mixture raw material. The slow-digestibl...

Embodiment 3

[0070] A low GI non-fried extruded instant noodle, comprising the following raw materials in parts by weight: 60 parts of wheat flour, 30 parts of whole wheat flour, 20 parts of high amylose corn starch, 8 parts of quinoa flour, 8 parts of buckwheat flour, 0.6 part of vegetable oil, konjac powder 0.6 parts, 0.3 parts of Artemisia gum, 0.1 parts of monoglycerides, 5 parts of resistant starch, 0.0002 parts of β-amylase (its enzyme activity is 65U / mL), 0.0002 parts of glucosidase transferase (its enzyme activity is 3000U / mL) mL), 50 parts of purified water.

[0071] The preparation method of this low GI non-fried extruded instant noodles comprises the following steps:

[0072] S1. Enzymatic hydrolysis: Take 35 parts of wheat flour, pour them into an enzymatic hydrolysis tank, add purified water, stir to form a uniform paste, add β-amylase and glucosidyl transferase, heat up to 50°C, and enzymatically hydrolyze for 2 hours to obtain a paste mixture raw material. The slow-digesti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com