Coal water slurry integrated processing system and method thereof

A treatment system and coal-water slurry technology, applied in the field of coalification gas, can solve problems such as high energy consumption, complicated process, and small increase in coal slurry concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

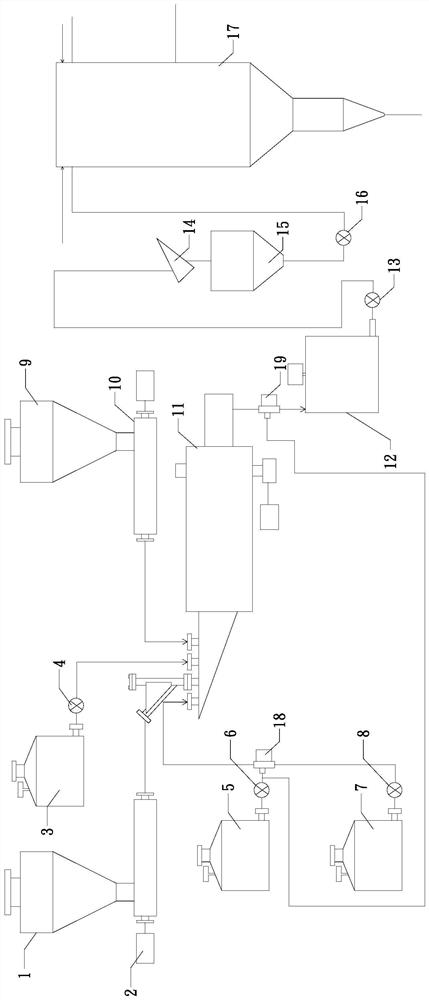

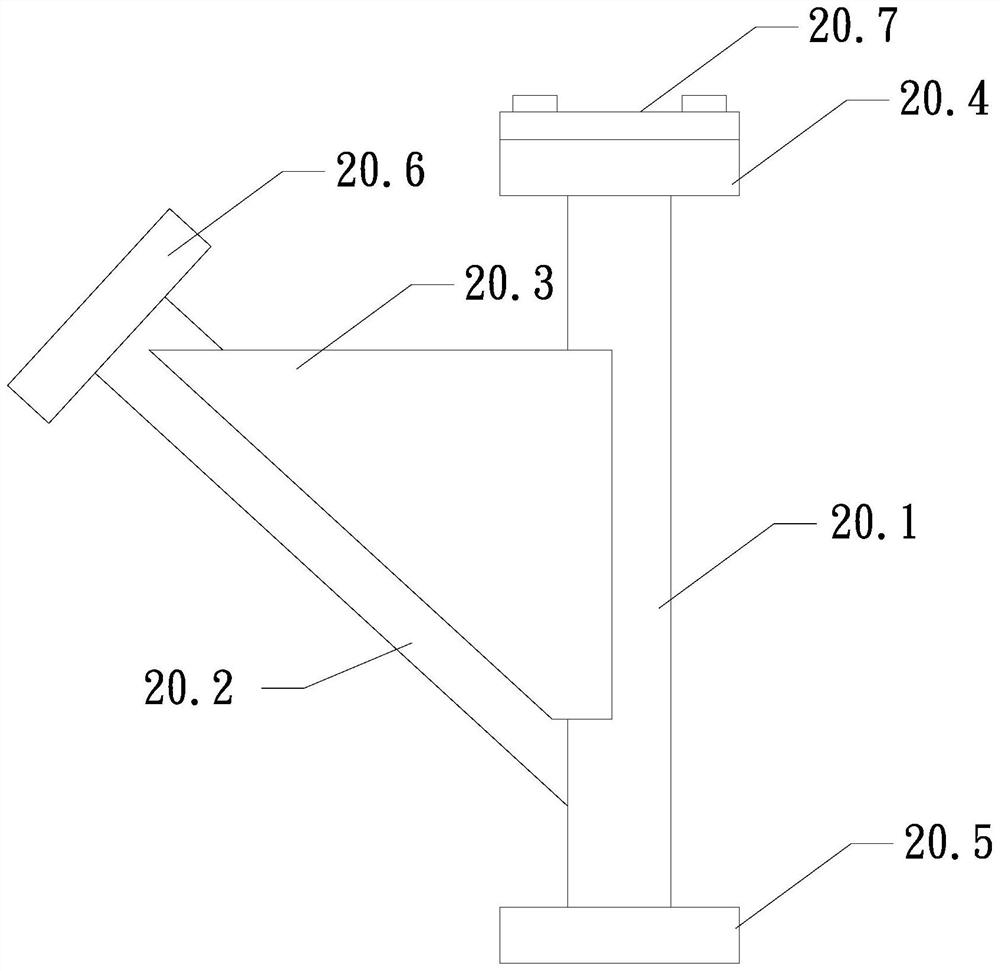

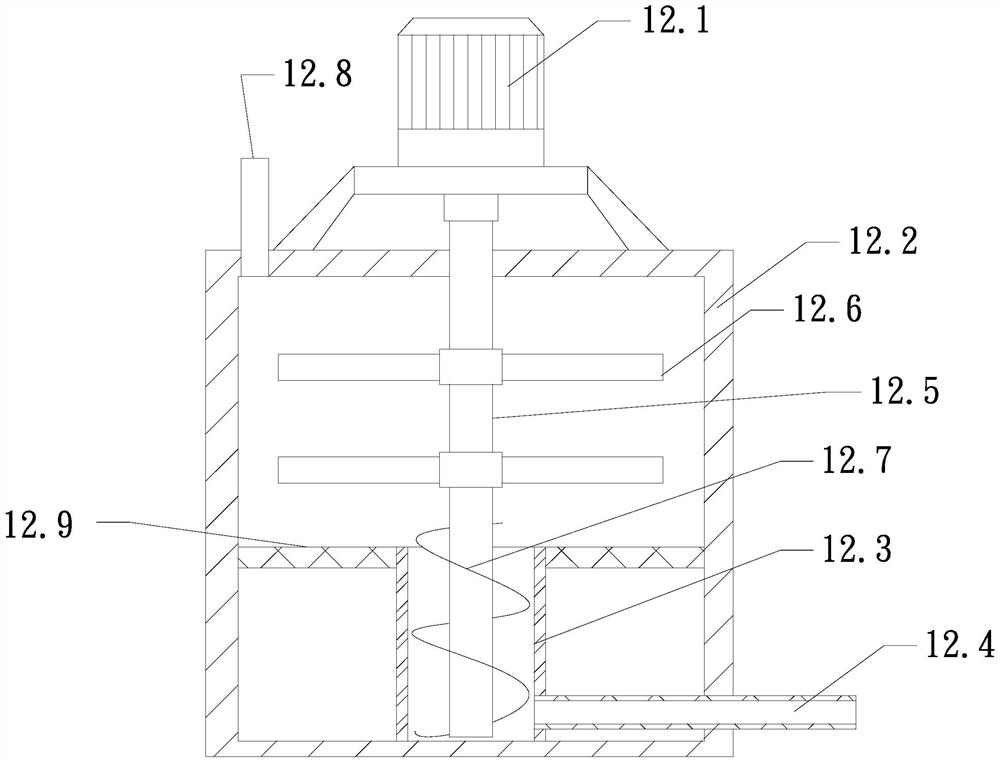

[0043] Such as Figure 1-4 As shown, the coal-water slurry integrated processing system includes the coal-water slurry preparation system used in the coal-water slurry preparation process, and the coal-water slurry preparation system includes a coal hopper 1, a weighing feeder 2, sodium hydroxide storage tank 3, lime storage hopper 9 and coal mill 11, the first feed port of the coal mill 11 is connected with a first control valve 18, the first control valve 18 has a first runner port, a second runner port and the third flow channel port, the second flow channel port and the third flow channel port of the first control valve 18 communicate with the water storage tank 5 and the additive tank 7 through pipelines respectively, and the pipeline between the water storage tank 5 and the first control valve 18 A water tank pump 6 is installed on the top, an additive pump 8 is installed on the pipeline between the additive tank 7 and the control valve, a weighing feeder 2 is connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com