Preparation of artificial super-wetting lotus-leaf-shaped Janus film

A lotus leaf and artificial technology, which is applied in the field of preparation of artificial super-wetting lotus leaf-shaped Janus films, can solve the problems of cumbersome steps, high cost, and complicated development process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] specific implementation plan

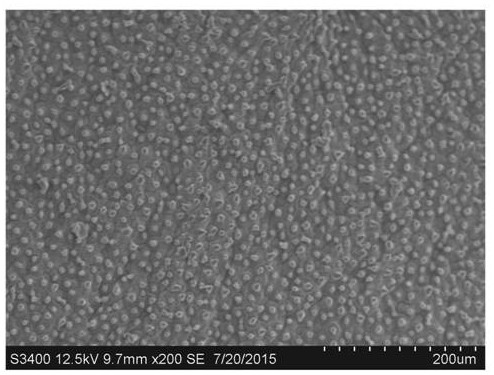

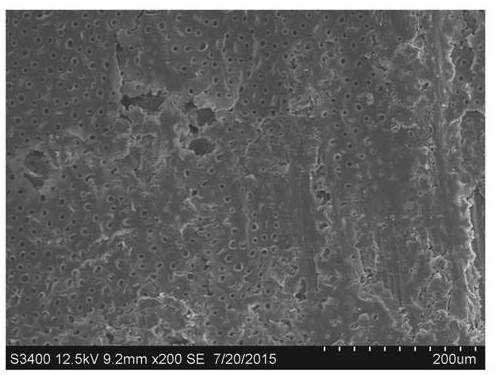

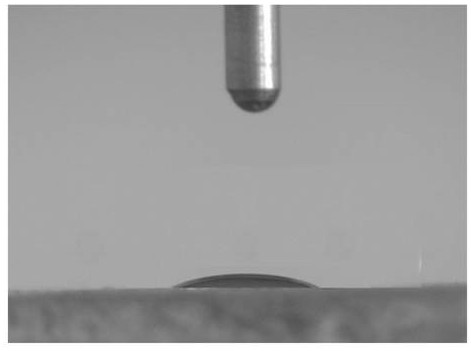

[0027] The preparation of an artificial super-wetting lotus-leaf-shaped Janus film of the present invention will be specifically described below in conjunction with the accompanying drawings and examples.

[0028] The present invention proposes the preparation of a kind of artificial superwetting lotus-leaf Janus film, specifically comprises several steps:

[0029] (1) PDMS mixed solution, the volume ratio of main agent PDMS and curing agent is 10:1;

[0030] (2) Pour the mixture of (1) into the surface of the silicon wafer, degas for a certain period of time, and cure for a certain period of time at a certain temperature, peel the PDMS elastomer from the surface of the Si wafer, and then cure for 24 hours, and cut into squares;

[0031] (3) Prepare PVB mixed solution;

[0032] (4) Put clean fresh lotus leaves flat on a petri dish, then pour the mixture in (1), dry and solidify to obtain a PDMS template;

[0033] (5) Coat the mixture in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com