Ramie bone nanocrystalline cellulose aerogel and preparation method thereof

A technology of nanocrystalline cellulose and ramie bone, applied in the field of thermal insulation materials, can solve the problems of large pore structure, poor thermal insulation effect, high thermal conductivity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] The invention provides a preparation method of ramie bone nanocrystalline cellulose airgel, comprising the following steps:

[0024] 1) osmotically concentrating the ramie bone nanocrystalline cellulose suspension to obtain ramie bone nanocrystalline cellulose hydrogel;

[0025] 2) The ramie bone nanocrystalline cellulose hydrogel obtained in the step 1) is sequentially subjected to spray freezing and vacuum freeze drying to obtain the ramie bone nanocrystalline cellulose aerogel.

[0026] The invention osmotically concentrates the ramie bone nanocrystalline cellulose suspension to obtain the ramie bone nanocrystalline cellulose hydrogel. The present invention uses ramie bone nanocrystalline cellulose suspension to prepare airgel, ramie bone resources are abundant, raw material resources are abundant, and the cost is cheap, which not only solves the problem of environmental pollution caused by ramie bone incineration, but also improves the comprehensive utilization valu...

Embodiment 1

[0046] Take 100g of ramie bone powder, add 500mL of distilled water, and steam-explode at 121°C for 20min; take 50g of pretreated ramie bone powder, add 1500mL of 10% NaOH solution, cook at 75°C for 6h, let it stand for 12h, and then filter it with suction. Soak the filter residue in 200mL distilled water for 2h, filter, repeat the operation 3 times, dry the filter residue to obtain ramie bone crude cellulose; take 30g ramie bone crude cellulose, add 750mL 5% H 2 o 2 React for 8 hours, then filter, rinse the filter residue with distilled water for 3 times, and dry the obtained ramie bone cellulose; take 2.0 g of ramie bone cellulose, add 20 mL of 68% sulfuric acid, and react with magnetic stirring at 55 ° C for 35 minutes, and control the stirring speed to 700 rpm. After cooling and standing for 5 hours, centrifuge at a speed of 5000 rpm for 10 minutes, remove the supernatant, wash the precipitate with an equal amount of distilled water, repeat the above centrifugation and was...

Embodiment 2

[0053] Get 20mL of the ramie bone nanocrystalline cellulose suspension prepared in Example 1 and place it in a 12kDa dialysis bag, immerse the dialysis bag in 15wt% dextran aqueous solution, replace the dextran aqueous solution once every 25h, until the ramie bone When the nanocrystalline cellulose concentration in the nanocrystalline cellulose suspension is 2.0 wt%, the osmotic concentration is completed, and the ramie bone nanocrystalline cellulose hydrogel is obtained;

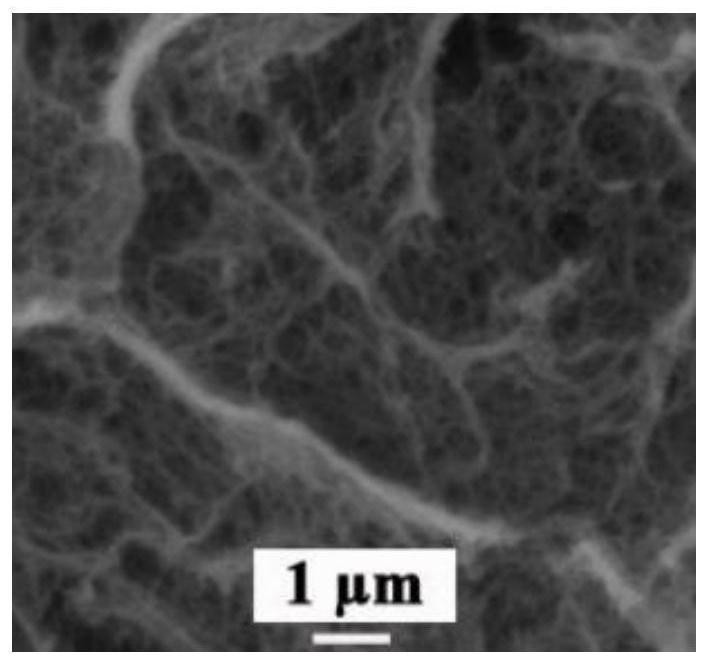

[0054] The ramie bone nanocrystalline cellulose hydrogel was sprayed with a stainless steel nozzle with an inner diameter of 0.2 mm under a constant pressure of 1.3 bar and frozen in a liquid nitrogen freezing container at -80 ° C to obtain a frozen sample with a thickness of 1.2 cm. The sample was placed in a vacuum freeze dryer and dried for 24 hours at -55°C and a vacuum of less than 0.1 mbar to obtain ramie bone nanocrystalline cellulose airgel.

[0055] The measured density of ramie bone nanocrystallin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com