Bone filling block with tantalum metal porous structure layer, manufacturing method and application

A technology of porous metal and manufacturing method, applied in the field of medical orthopedic bionic materials, can solve the problems of high power consumption of 3D printing, harm to human body, and complicated process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

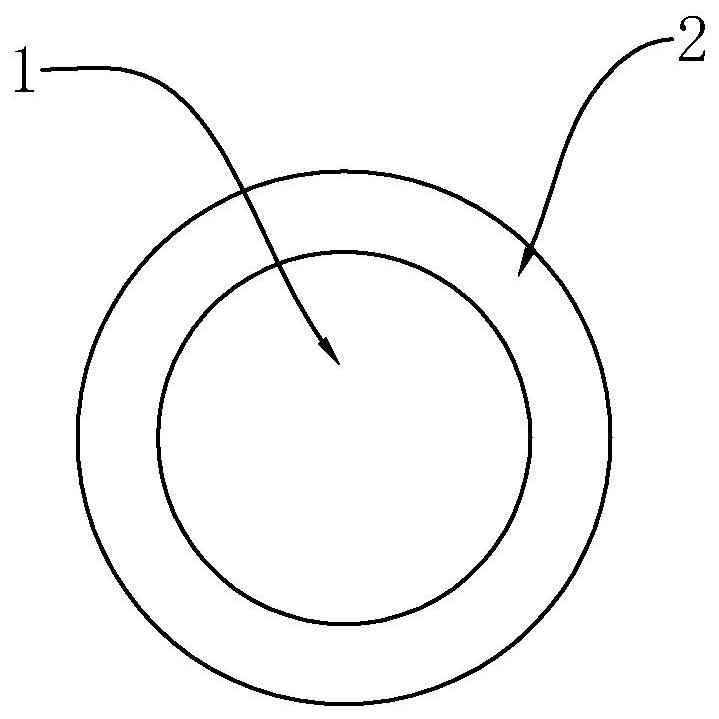

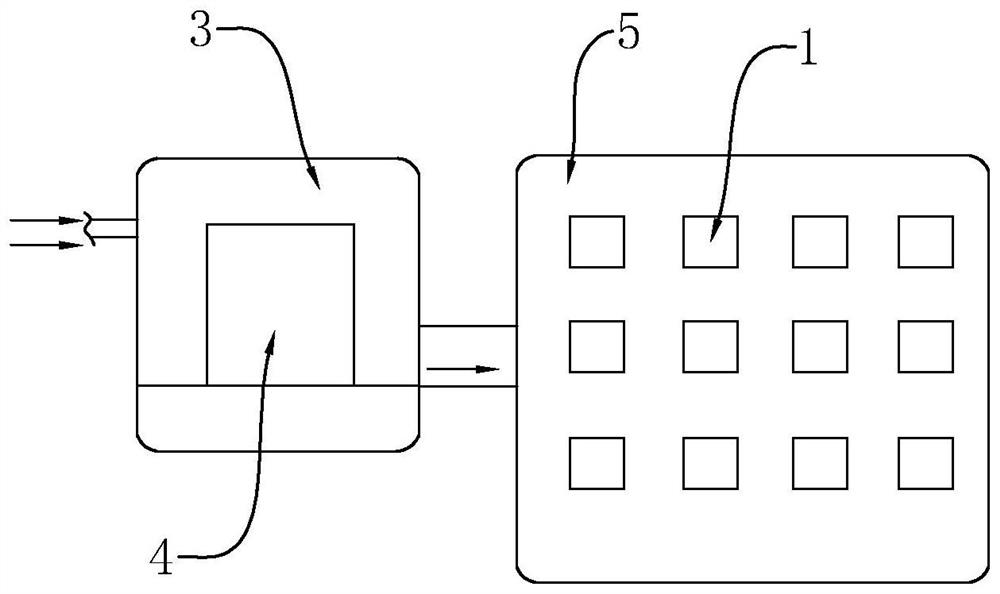

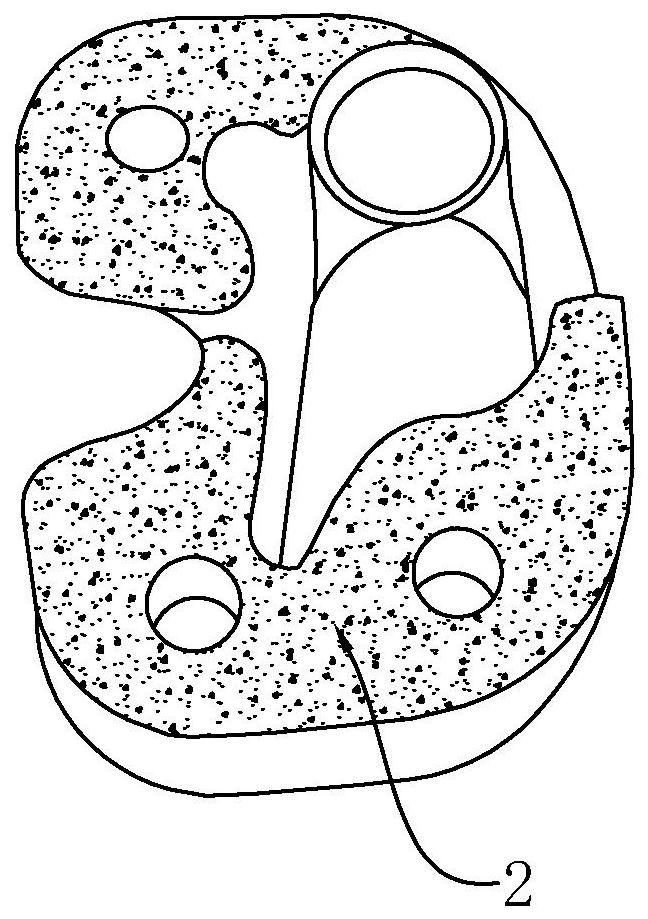

[0033] The embodiment of the present application discloses a bone filling block with a tantalum metal porous structure layer, referring to figure 1 , including a substrate 1 and a tantalum metal porous structure layer 2 on the surface of the substrate 1 . Compared with titanium alloy, tantalum metal has better biocompatibility, smaller elastic modulus, more effective reduction of stress shielding, higher porosity, and more conducive to inducing bone ingrowth, which is more conducive to bone remodeling. It is an ideal bone implant material.

[0034] Wherein, in this embodiment, the matrix 1 is a network glassy carbon body, the tantalum metal porous structure layer 2 has a pore diameter of 200-800 μm, a wire diameter of 100-700 μm, and a porosity of 50%-80%.

[0035] Reticular glassy carbon is a three-dimensional network microporous material composed of glassy foam. It has low density, high chemical stability, specific surface area, and high structural strength. The pore diamet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com