Preparation method of sturgeon caviar extract

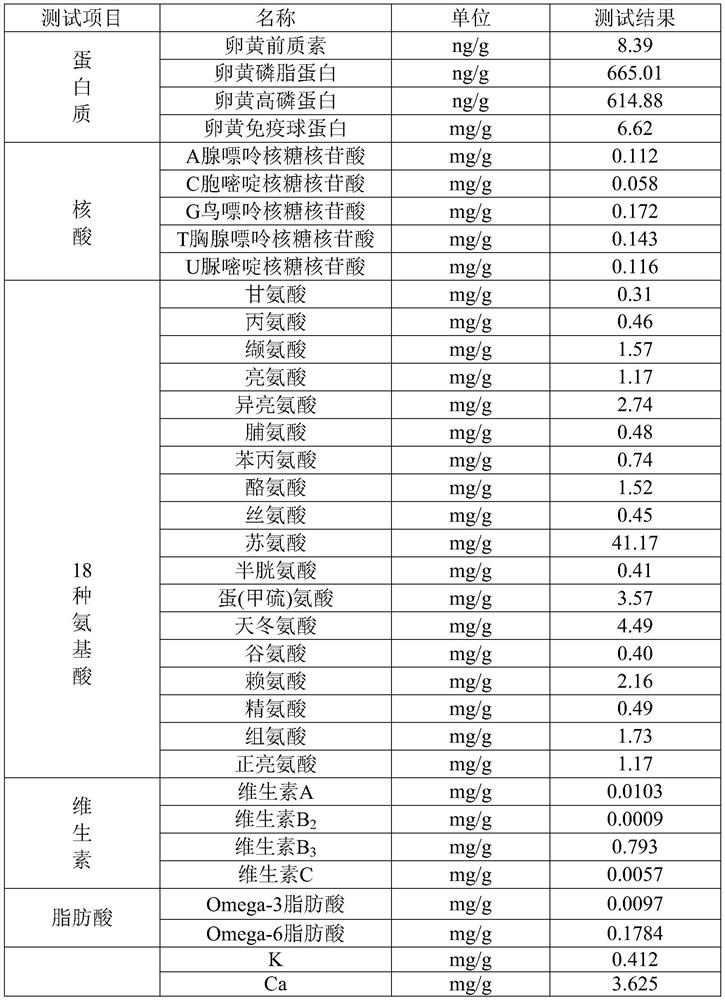

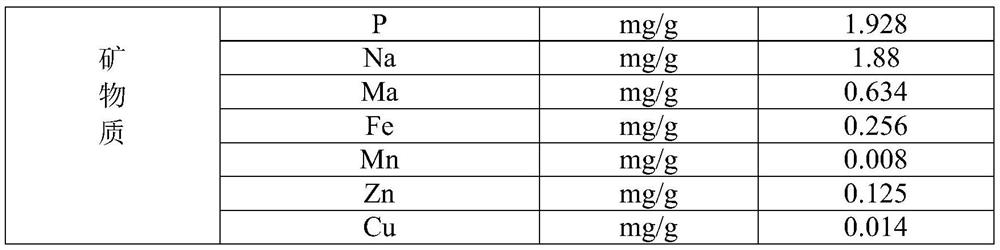

A technology of sturgeon caviar and extracts, which can be used in skin care preparations, medical preparations containing active ingredients, pharmaceutical formulas, etc. It can solve the problems of wasting other nutrients and not really retaining the nutritional elements of sturgeon caviar

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] A preparation method of sturgeon caviar extract, comprising the following steps:

[0024] 1. Carry out decolorization, deodorization and desodium treatment on sturgeon caviar to obtain three de-treated sturgeon caviar;

[0025] The three removal treatment solution is a mixed extract of 2%-3% sodium chloride, 0.24%-0.3% hydrogen peroxide, 0.1%-0.15% calcium chloride and 0.1%-0.15% glacial acetic acid, and the quality of the three removal treatment solution is The mass of the treated sturgeon caviar is 6-8 times; the triple removal treatment is a constant temperature treatment, the temperature of the constant temperature treatment is 12-20°C, and the time of the constant temperature treatment is 60-100min.

[0026] 2. Cleaning treatment: clean with aseptic clean water to remove impurities and control the water to obtain clean sturgeon caviar.

[0027] 3. Enzymatic hydrolysis: Grind the three-de-cleaned sturgeon caviar into a slurry, add 1.5-2.5 times the amount (relative...

Embodiment 1

[0032] 1. Carry out decolorization, deodorization and desodium treatment to sturgeon caviar: put sturgeon caviar (50g) into the preparation treatment solution (2.5% sodium chloride, 0.24% hydrogen peroxide, 0.1% calcium chloride and 0.1% Glacial acetic acid mixed extract), the quality of the treatment solution is 6-8 times that of sturgeon caviar, the temperature of the treatment solution is adjusted at 12°C-14°C, and the treatment time is 60-70min.

[0033] 2. Cleaning treatment: add 6-8 times the amount (relative to the quality of the treated sturgeon caviar) of sterile clean water to the caviar after three removals, rinse at a constant temperature of 12-14°C for 15-20min, and use Repeatedly wash with sterile clean water until there are no impurities, remove the water and set aside to obtain clean sturgeon caviar.

[0034] 3. Enzymatic hydrolysis: Grind the cleaned sturgeon caviar into a slurry, add 1.5 times the amount (relative to the quality of clean sturgeon caviar) of d...

Embodiment 2

[0038] 1. Carry out decolorization, deodorization and desodium treatment to sturgeon caviar: put sturgeon caviar (50g) into the preparation treatment solution (2.8% sodium chloride, 0.26% hydrogen peroxide, 0.12% calcium chloride and 0.12% Glacial acetic acid mixed extract), the quality of the treatment solution is 6-8 times that of sturgeon caviar, the temperature of the treatment solution is adjusted at 14°C-16°C, and the treatment time is 70-80min.

[0039] 2. Cleaning treatment: Add 6-8 times the amount (relative to the quality of the treated sturgeon caviar) of sterile clean water to the caviar after three removals, rinse at a constant temperature of 14-16°C for 15-20min, and use Repeatedly wash with sterile clean water until there are no impurities, remove the water and set aside to obtain clean sturgeon caviar.

[0040] 3. Enzymatic hydrolysis: Grind the cleaned sturgeon caviar into a slurry, add 2.5 times the amount (relative to the quality of clean sturgeon caviar) of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com