Preparation method and application of dandelion leaf water-soluble crude extract

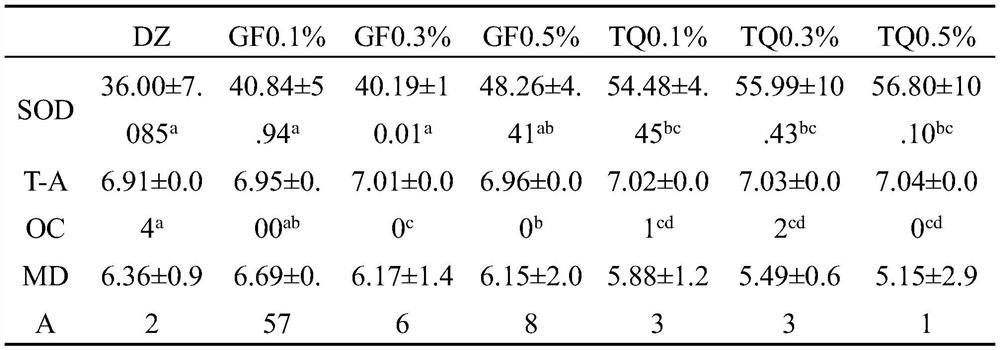

A dandelion leaf and water-soluble technology, which is applied in the fields of application, medical preparations containing active ingredients, animal feed, etc., can solve the problems of complex operation, low extraction rate of water extraction technology, and lack of application technology, and achieve high content of active ingredients , excellent anti-inflammatory activity, and simple steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] The embodiment of the present invention provides a method for preparing a water-soluble crude extract of dandelion leaves, comprising the following steps:

[0036] (1) Water extraction pretreatment: add dandelion in cellulase solution, soak, obtain the dandelion of pretreatment; Described dandelion leaf is to wash the leaves of freshly picked dandelion dandelion, cut into sections 3 ~ 5cm, first in Lose 20% to 40% of water in a cool place, then dry in the sun or bake in an oven at 60-75°C for 4-6 hours; the cellulase is 0.1% cellulase, and the enzyme activity of the cellulase is 5000 ~10000U / g; the mass volume ratio of the dandelion leaf and the cellulase solution is 1g:(5mL~10mL), the pH value is adjusted to 4, the soaking temperature is 50~80°C, and the time is 6~12h;

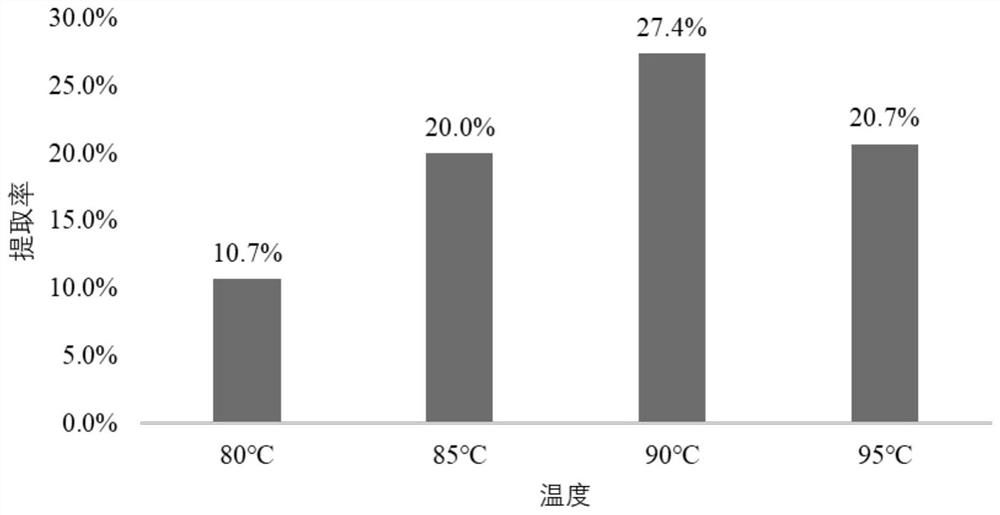

[0037] (2) Water leaching: the pretreated dandelion is subjected to multiple water leaching, the leaching solution is combined, and the extracting solution is obtained after filtering; the pressure of ...

Embodiment 1

[0043] Embodiment 1 of the present invention discloses a kind of preparation method of dandelion water extract, specifically comprises the following steps:

[0044] (1) Cut the washed leaves of "Binpu No. 1" into 4cm sections, lose 25% of the water in a cool place, and then dry them in the sun or bake them in an oven at 65°C for 6 hours to obtain dandelion leaves; then add dandelion leaves according to 1g of dandelion leaves Add 6mL of 0.1% cellulase solution to the cellulase solution for soaking at 60°C for 8 hours;

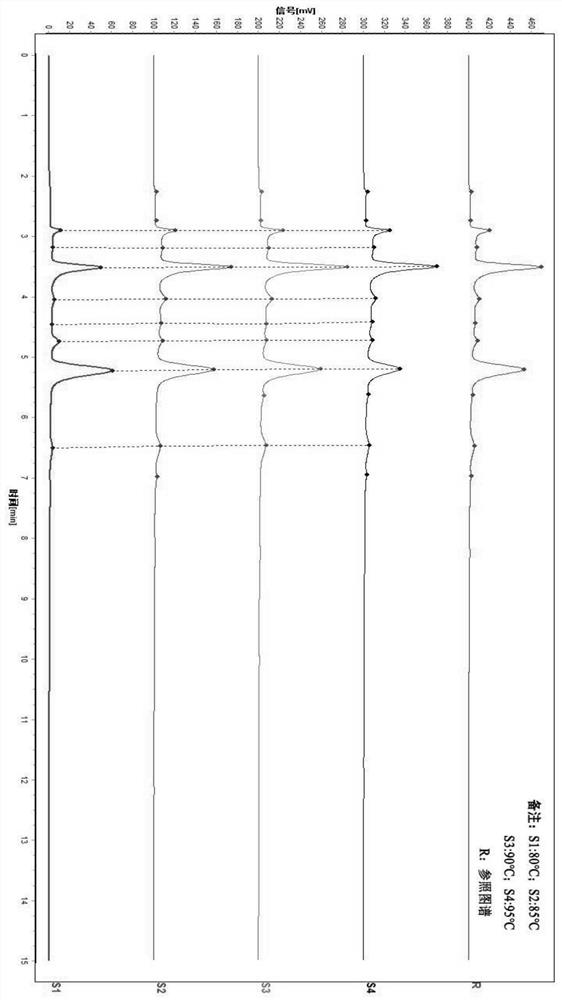

[0045] (2) The negative pressure conditions in the water extraction process are: -0.05MPa, the temperature is 80°C, add 10 times the amount of water of the pretreated dandelion for the first extraction, and the time is 4 hours, and add the first extraction for the second extraction. Add 6 times the amount of water to the extract for 3 hours, add 2 times the amount of water to the second extract for 2 hours, combine the first extract, the second extract and the t...

Embodiment 2

[0048] Embodiment 2 of the present invention discloses a kind of preparation method of dandelion water extract, specifically comprises the following steps:

[0049] (1) Cut the washed leaves of "Binpu No. 1" into 4cm sections, lose 25% of the water in a cool place, and then dry them in the sun or bake them in an oven at 65°C for 6 hours to obtain dandelion leaves; add 6mL of 0.1% fiber to 1g of dandelion leaves The proportion of the enzyme solution is added to the cellulase solution for soaking, the soaking temperature is 60°C, and the soaking time is 8h;

[0050] (2) The negative pressure conditions for extraction are: -0.05MPa, temperature is 85°C, add 10 times the amount of water of pretreated dandelion for the first extraction, and the time is 4h, and add the first extraction for the second extraction 6 times the amount of water for 3 hours, add 2 times the amount of water for the second extraction for 2 hours, and combine the first extract, the second extract and the thir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com