Preparation method of silver doped carbon dot based NO release-type wound dressing, and product and applications of product

A technology of wound dressing and silver doping, which is applied in the fields of medical formula, medical science, bandages, etc., and can solve problems such as high doses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

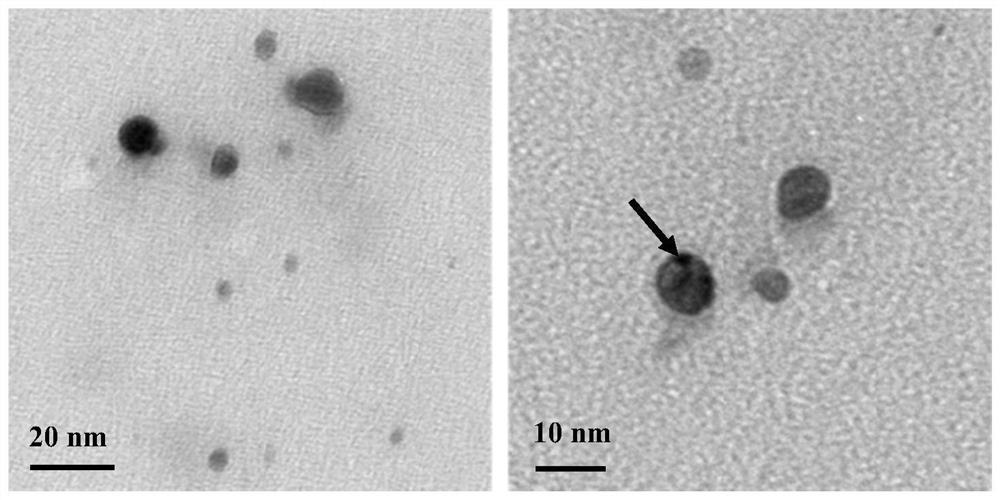

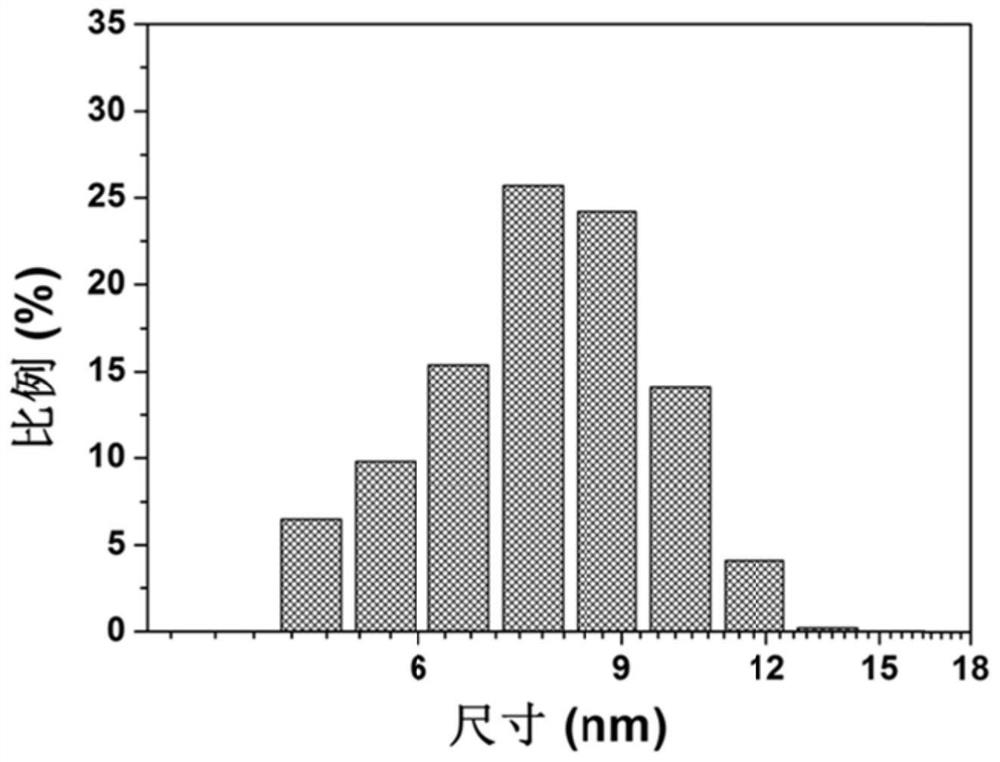

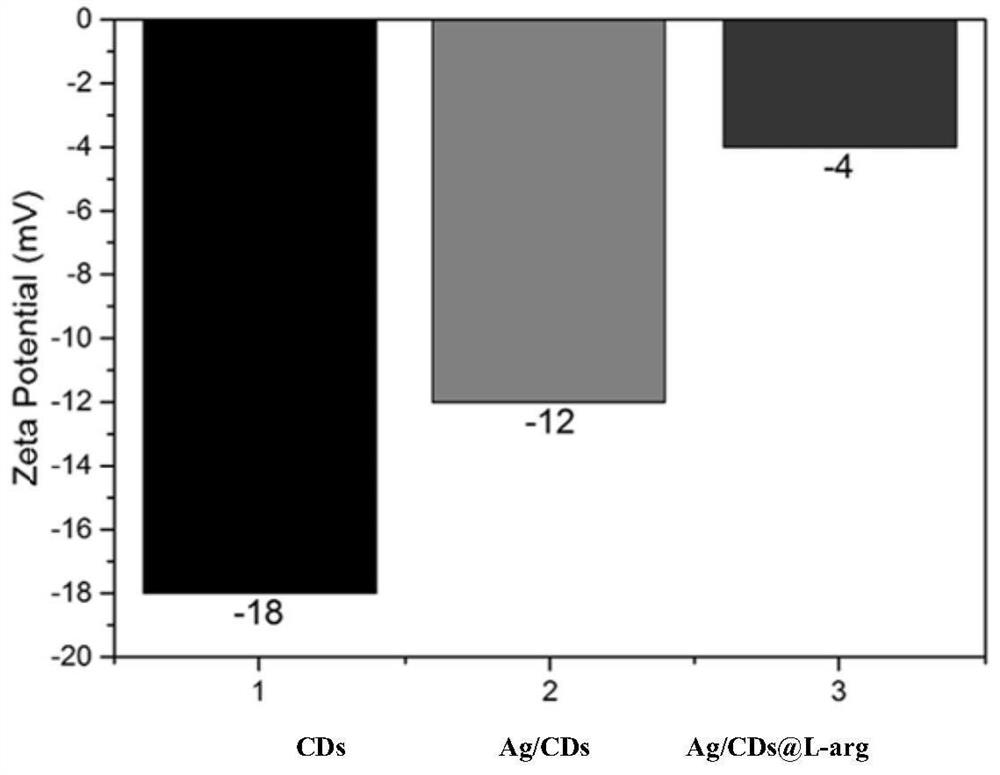

[0038] Preparation of NO-releasing wound dressing based on silver-doped carbon dots

[0039] Step 1: Weigh 1mg of CA, add deionized water, stir at 500rpm for 15min at 25°C, and set the volume to 100mL for mixing.

[0040] Step 2. Transfer 30 mL of the stirred solution into a polytetrafluoroethylene (Teflon)-lined autoclave and heat at 170° C. for 5 hours.

[0041] In step 3, after the reactor is naturally cooled to room temperature, a carbon dot solution is obtained.

[0042] Step 4, 100 μL of carbon dot solution was added dropwise to 800 μL of 10 mM AgNO with stirring at 500 rpm 3 The solution was reacted for two minutes, and then the mixture solution was reacted at 90° C. for 60 minutes to obtain a purple-red Ag / CDs composite solution.

[0043] Step 5, dialyze the above solution for 6 hours with a dialysis bag with a molecular weight cut-off of 8KD-14KD, and then add 200 μL of L-arginine solution (manufacturer: McLean, model: L800637) to the solution obtained after the dia...

Embodiment 2

[0046] Preparation of NO-releasing wound dressing based on silver-doped carbon dots

[0047] Step 1: Weigh 1mg of CA, add deionized water, stir at 500rpm for 15min at 25°C, and set the volume to 100mL for mixing.

[0048] Step 2. Transfer 30 mL of the stirred solution into a polytetrafluoroethylene (Teflon)-lined autoclave and heat at 170° C. for 5 hours.

[0049] In step 3, after the reactor is naturally cooled to room temperature, a carbon dot solution is obtained.

[0050] Step 4, 100 μL of carbon dot solution was added dropwise to 800 μL of 10 mM AgNO with stirring at 500 rpm 3 The solution was reacted for two minutes, and then the mixture solution was reacted at 90° C. for 30 minutes to obtain a purple-red Ag / CDs composite solution.

[0051] Step 5, dialyze the above solution for 6 hours with a dialysis bag with a molecular weight cut-off of 8KD-14KD, and then add 200 μL of L-arginine solution (manufacturer: McLean, model: L800637) to the solution obtained after the dia...

Embodiment 3

[0053] Preparation of NO-releasing wound dressing based on silver-doped carbon dots

[0054] Step 1: Weigh 1mg of CA, add deionized water, stir at 500rpm for 15min at 25°C, and set the volume to 100mL for mixing.

[0055] Step 2. Transfer 30 mL of the stirred solution into a polytetrafluoroethylene (Teflon)-lined autoclave and heat at 170° C. for 5 hours.

[0056] In step 3, after the reactor is naturally cooled to room temperature, a carbon dot solution is obtained.

[0057] Step 4, under stirring at 500rpm, 100 μL of carbon dot solution was added dropwise to 800 μL concentration of (10 mM AgNO 3 The solution was reacted for two minutes, and then the mixture solution was reacted at 90° C. for 90 minutes to obtain a purple-red Ag / CDs composite solution.

[0058] Step 5, dialyze the above solution for 6 hours with a dialysis bag with a molecular weight cut-off of 8KD-14KD, and then add 200 μL of L-arginine solution (manufacturer: McLean, model: L800637) to the solution obtain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com