Cement-based waterproof material and preparation technology thereof

A waterproof material and preparation technology, applied in manufacturing tools, sustainable waste treatment, solid waste management, etc., can solve the problems of difficult control of moisture in cement substrates, poor crack resistance of high molecular polymers, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0036] As an embodiment of the present invention, the inorganic filler includes talcum powder and mica powder; mica powder has good elasticity and toughness, and can improve the insulation, high temperature resistance, acid and alkali resistance, corrosion resistance, and adhesion of cement-based waterproof materials. Strong strength and other characteristics; talcum powder can improve the wear resistance and anti-skid performance of waterproof materials.

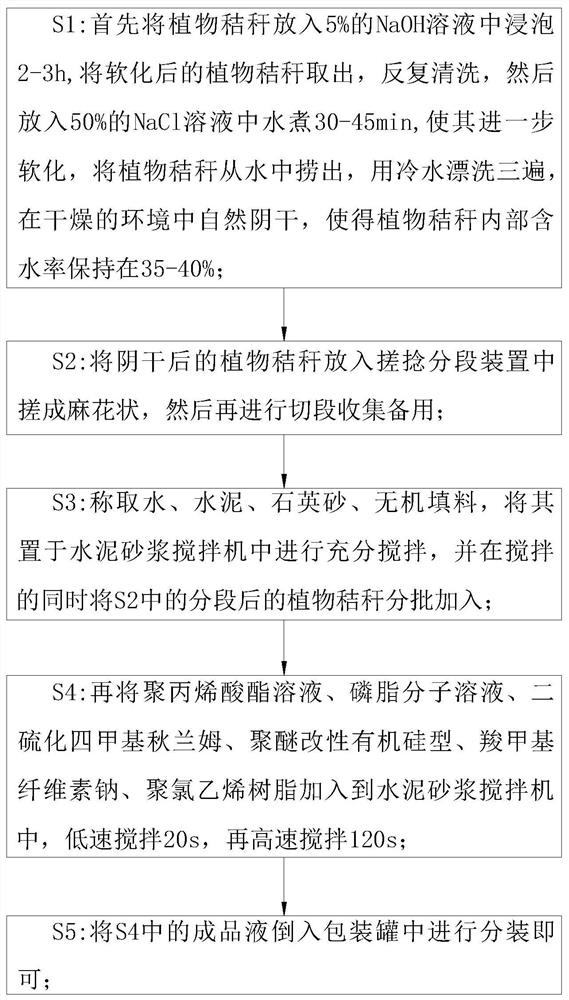

[0037] A preparation process of a cement-based waterproof material, the preparation process is applicable to any one of the above-mentioned cement-based waterproof materials, the preparation process comprises the following steps:

[0038] S1: first put the plant straw into 5% NaOH solution and soak for 2-3 hours, take out the softened plant straw, wash it repeatedly, then put it into 50% NaCl solution and boil it for 30-45min to further soften it, Take the plant straw out of the water, rinse it with cold water three times, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com