Metallocene linear low-density polyethylene reinforced wrapping film manufacturing process

A low-density polyethylene, metallocene linear technology, applied in the direction of flat products, applications, household appliances, etc., can solve the problem of raw materials can not play a role

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

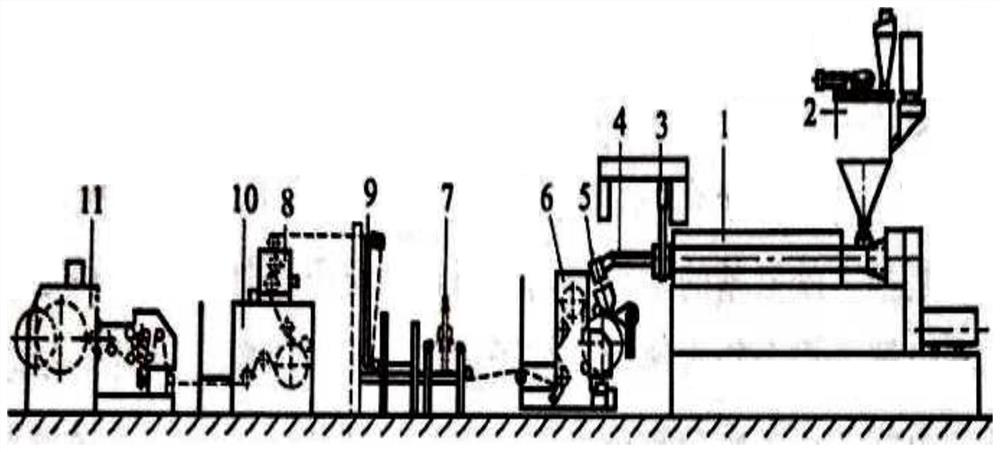

[0031] The technical solutions of the present invention will be further described in detail below through embodiments and in conjunction with the accompanying drawings.

[0032] The manufacturing process of metallocene LLDPE reinforced stretch film comprises the following steps:

[0033] 1) The raw materials are dried, batched and mixed, and fed through a vacuum hopper;

[0034] 2) Extrude the material through the equipment, and filter the semi-finished product at the extruded place through the filter;

[0035] 3) The filtered product is processed through the die head, and the semi-finished product is cast and cooled;

[0036] 4) Then, the thickness gauge-corona treatment-swing edge traction and other processes are carried out on the finished product in sequence;

[0037] 5) Flatten the finished product to remove static electricity;

[0038] 6) Finally, the finished product is wound up.

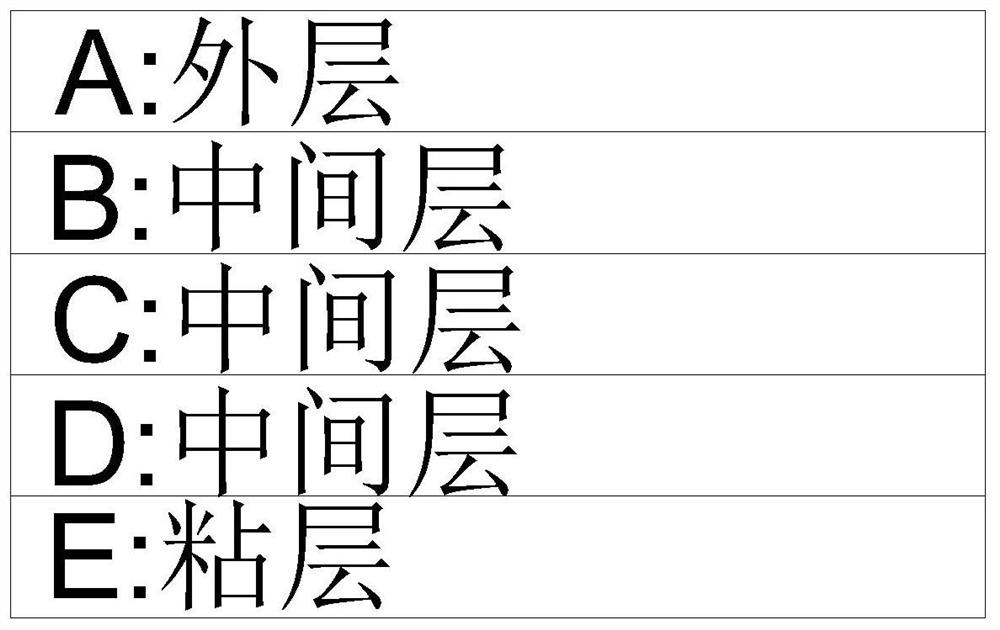

[0039] In the stretch film structure, mLLDPE-a and mLLDPE-b are metallocene linear lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com