Method for preparing graphene electrothermal film based on flexible porous fiber material

A porous fiber and graphene technology, which is applied in the field of graphene electric heating film preparation, can solve the problems of affecting normal use, poor experience effect, unable to meet high performance and high reliability use, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

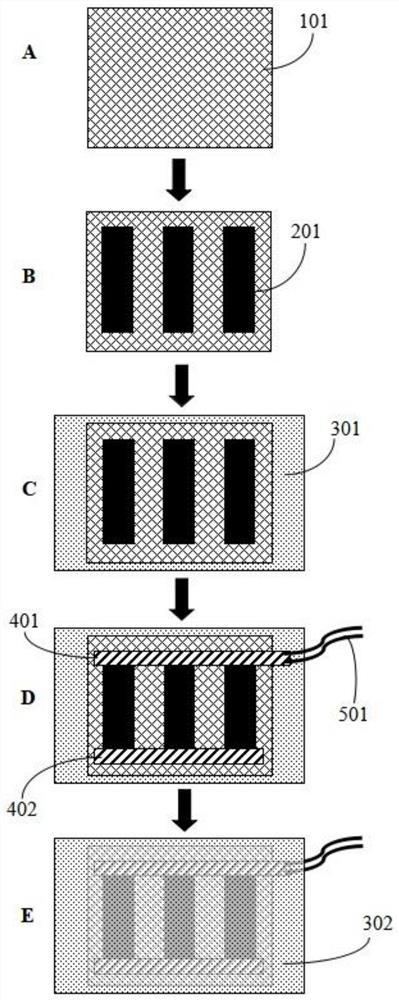

[0040] Method for preparing graphene electric heating film based on flexible porous fiber material:

[0041] 1) Using LIG technology to prepare a three-dimensional graphene conductive film pattern on the surface of 10 micron thick polyimide porous fiber paper, and ensure that the surface is covered with a polyimide porous fiber paper bottom layer (about 2 microns thick) Not graphitized. LIG uses laser scanning equipment. The laser light source is a carbon dioxide laser with a wavelength of 10.6 microns, a power of 4.8W, and a pulse time of 20 microseconds.

[0042] 2) Rolling the graphene conductive film obtained in 1) with a roller pressing machine, the processing conditions are: the pressure is 0.6 MPa, and the speed is 1.5 m / min;

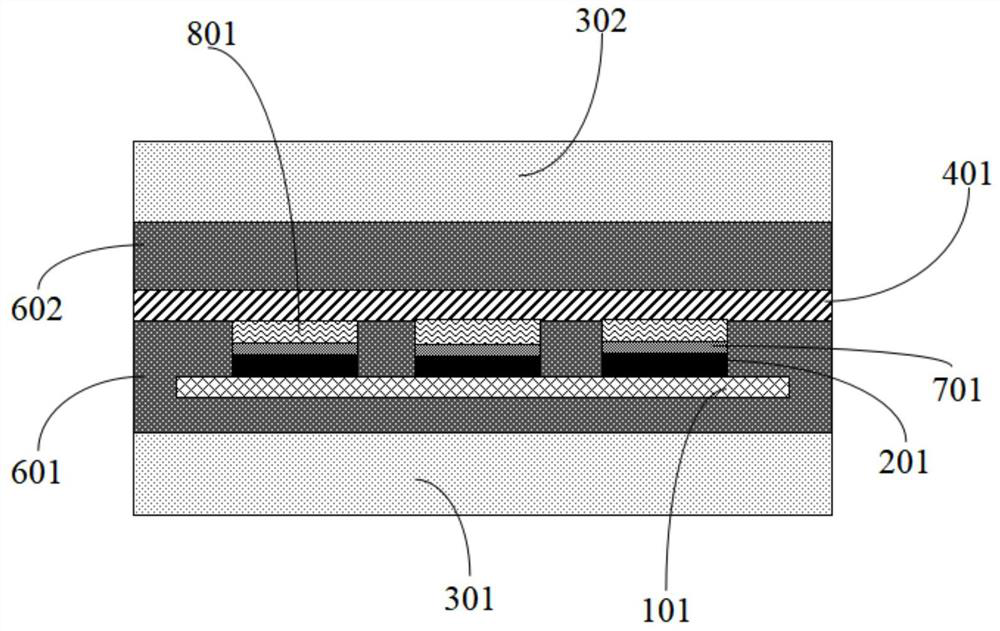

[0043] 3) The graphene conductive film obtained in 2), using 20 micron thick TPU hot melt adhesive as the adhesive layer, is hot pressed to the surface of the knitted fabric by hot pressing to form a knitted fabric / graphene composite structure. The hot...

Embodiment 2

[0047] Method for preparing graphene electric heating film based on flexible porous fiber material:

[0048] 1) Using LIG technology to prepare a three-dimensional graphene conductive film pattern on the surface of 10 micron thick polyimide porous fiber paper, and ensure that the surface is covered with a polyimide porous fiber paper bottom layer (about 2 microns thick) Not graphitized. LIG uses laser scanning equipment. The laser light source is a carbon dioxide laser with a wavelength of 10.6 microns, a power of 4.8W, and a pulse time of 20 microseconds.

[0049] 2) Rolling the graphene conductive film obtained in 1) with a roller pressing machine, the processing conditions are: the pressure is 0.6 MPa, and the speed is 1.5 m / min;

[0050] 3) In order to further improve the flexibility of the electric heating film, a laser cutting machine is used to cut the polyimide porous fiber paper whose surface is not graphitized on the graphene conductive film pattern;

[0051] 4) The graphen...

Embodiment 3

[0055] Method for preparing graphene electric heating film based on flexible porous fiber material:

[0056] 1) Using LIG technology to prepare a three-dimensional graphene conductive film pattern on the surface of 20 microns thick polyimide porous fiber paper, and ensure that the surface is covered with a polyimide porous fiber paper bottom layer (about 12 microns thick) with graphene film Not graphitized. LIG uses laser scanning equipment. The laser light source is a carbon dioxide laser with a wavelength of 10.6 microns, a power of 4.8W, and a pulse time of 20 microseconds.

[0057] 2) The graphene conductive film obtained in 1) is rolled by a roller press, and the treatment conditions are: the pressure is 0.6 MPa and the speed is 1.5 m / min;

[0058] 3) Using the graphene conductive film obtained in 2), heat-press a 20-micron thick TPU hot melt adhesive to the surface of the non-graphitized polyimide porous fiber paper by hot pressing to form TPU / polyimide porous Fiber paper / gra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com