Chitosan and graphene oxide nano-hydrogel plugging agent and water-based drilling fluid

A nano-hydrogel, water-based drilling fluid technology, applied in the field of water-based drilling fluid, to achieve the effect of good performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

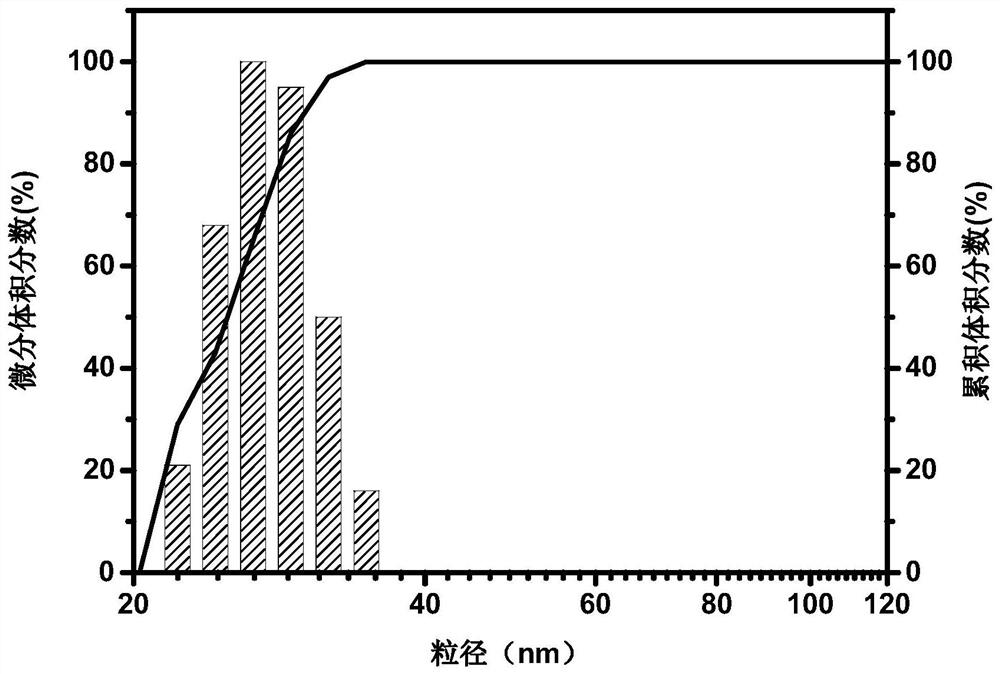

Embodiment 1

[0025] 1. Synthesis of chitosan graphene oxide nano hydrogel plugging agent:

[0026] (1) Preparation of oxidized konjac: Dissolve 8g of konjac in 450mL of distilled water, add 8.5g of sodium periodate, stir evenly at a temperature of 25°C and react in the dark for 12h, add 50mL of ethylene glycol and stir for 4h to terminate the reaction. Dialyze in a dialysis bag with a molecular weight of 3500 for 72 hours, centrifuge, and dry the supernatant at a temperature of 40-50° C. to obtain oxidized konjac.

[0027] (2) Preparation of graphene oxide aqueous solution: add 2g of graphite powder, 2g of potassium persulfate and 2g of phosphorus pentoxide into the reactor, then add 25mL of concentrated sulfuric acid, react at a temperature of 80°C for 8h, and wait for the temperature to drop slowly to After 25°C, the product was filtered, washed, and dried to obtain pre-oxidized graphite powder. Take 1.5g of pre-oxidized graphite powder into the reactor, add 100mL of concentrated sulfur...

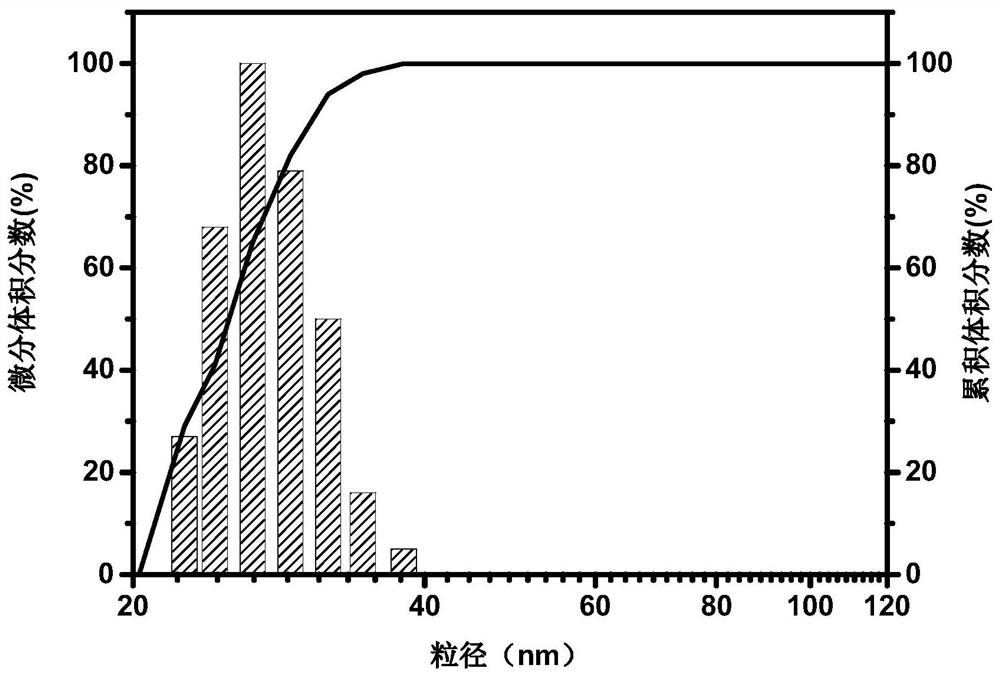

Embodiment 2

[0032] 1. Synthesis of chitosan graphene oxide nano hydrogel plugging agent:

[0033] (1) Preparation of oxidized konjac: 6g of konjac was dissolved in 400-500mL distilled water, 6g of sodium periodate was added, stirred evenly at a temperature of 20°C, and then reacted in the dark for 12h, and 60mL of ethylene glycol was added and stirred for 4h to terminate the reaction. Dialyze in a dialysis bag with a molecular weight cut-off of 3500 for 72 hours, centrifuge, and dry the supernatant at a temperature of 40-50° C. to obtain oxidized konjac.

[0034] (2) Preparation of graphene oxide aqueous solution: add 2.4g of graphite powder, 1.6g of potassium persulfate and 1.6g of phosphorus pentoxide into the reactor, then add 30mL of concentrated sulfuric acid, and react at a temperature of 85°C for 8h. After slowly lowering to 20°C, the product was filtered, washed, and dried to obtain pre-oxidized graphite powder. Take 2g of pre-oxidized graphite powder into the reactor, add 100mL ...

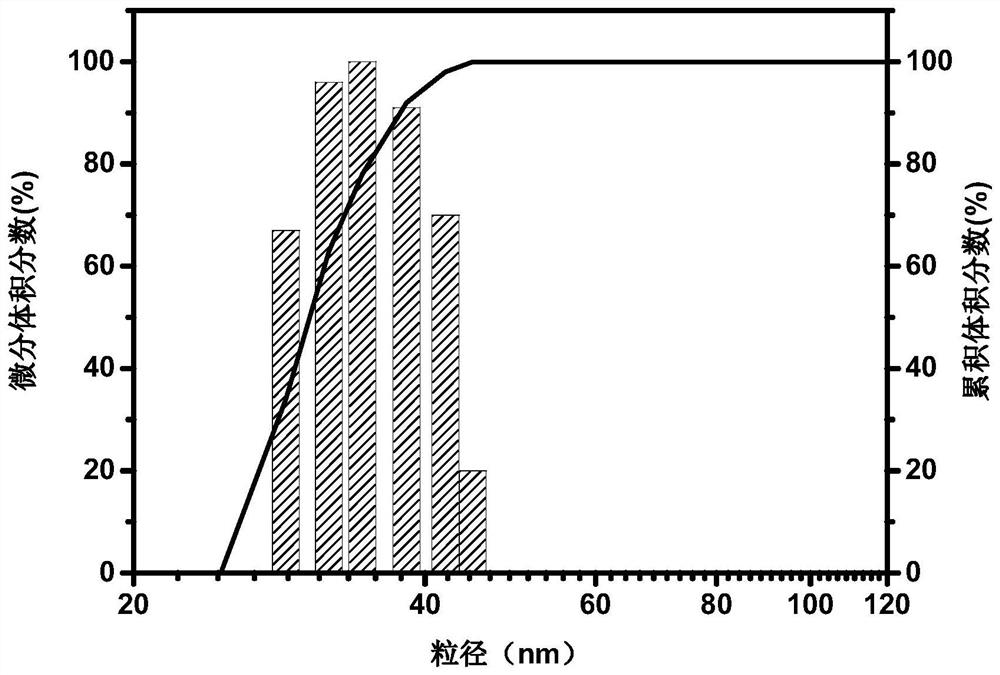

Embodiment 3

[0038] 1. Synthesis of chitosan graphene oxide nano hydrogel plugging agent:

[0039] (1) Preparation of oxidized konjac: 7g konjac was dissolved in 440mL distilled water, 8g sodium periodate was added, stirred evenly at a temperature of 24°C and reacted in the dark for 12h, and 80mL ethylene glycol was added to stir for 3h to terminate the reaction. Dialyze in a 3500 dialysis bag for 72 hours, centrifuge, and dry the supernatant at a temperature of 40-50° C. to obtain oxidized konjac.

[0040] (2) Preparation of graphene oxide aqueous solution: 2.6g of graphite powder, 1.8g of potassium persulfate and 1.8g of phosphorus pentoxide were added to the reactor, then 24mL of concentrated sulfuric acid was added, and reacted for 6h at a temperature of 78°C. After the temperature was slowly lowered to 26°C, the product was filtered, washed, and dried to obtain pre-oxidized graphite powder. Take 1.6g of pre-oxidized graphite powder into the reactor, add 100mL of concentrated sulfuric...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com