Stacking dyeing method and equipment

A dyeing method and dyeing equipment technology, applied in the field of textile dyeing, can solve the problems of low dye utilization rate, easy hydrolysis of dye, low dye utilization rate and waste water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

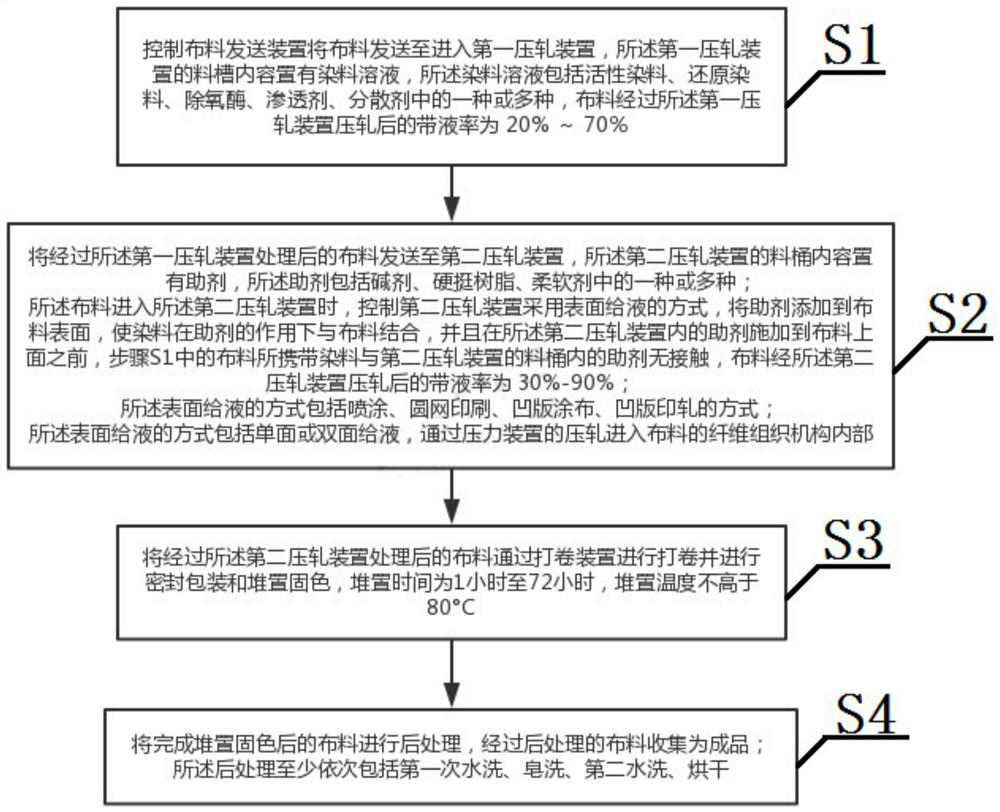

[0053] see figure 1 , a stacking dyeing method provided in the present embodiment comprises:

[0054] S1. Control the cloth sending device to send the cloth to the first calendering device, the trough of the first calendering device contains a dye solution, and the dye solution includes reactive dyes, vat dyes, oxygen-scavenging enzymes, and penetrants 1. One or more of the dispersants, the liquid-carrying rate of the cloth after being rolled by the first rolling device is 20% to 70%;

[0055] S2. Sending the cloth processed by the first rolling device to the second rolling device, the bucket of the second rolling device contains auxiliary agents, and the auxiliary agents include alkali agent, stiffening resin, One or more of softeners;

[0056] When the cloth enters the second calendering device, the second calendering device is controlled to use the method of surface liquid supply, and the auxiliary agent is added to the cloth surface, so that the dye is combined with the ...

Embodiment 2

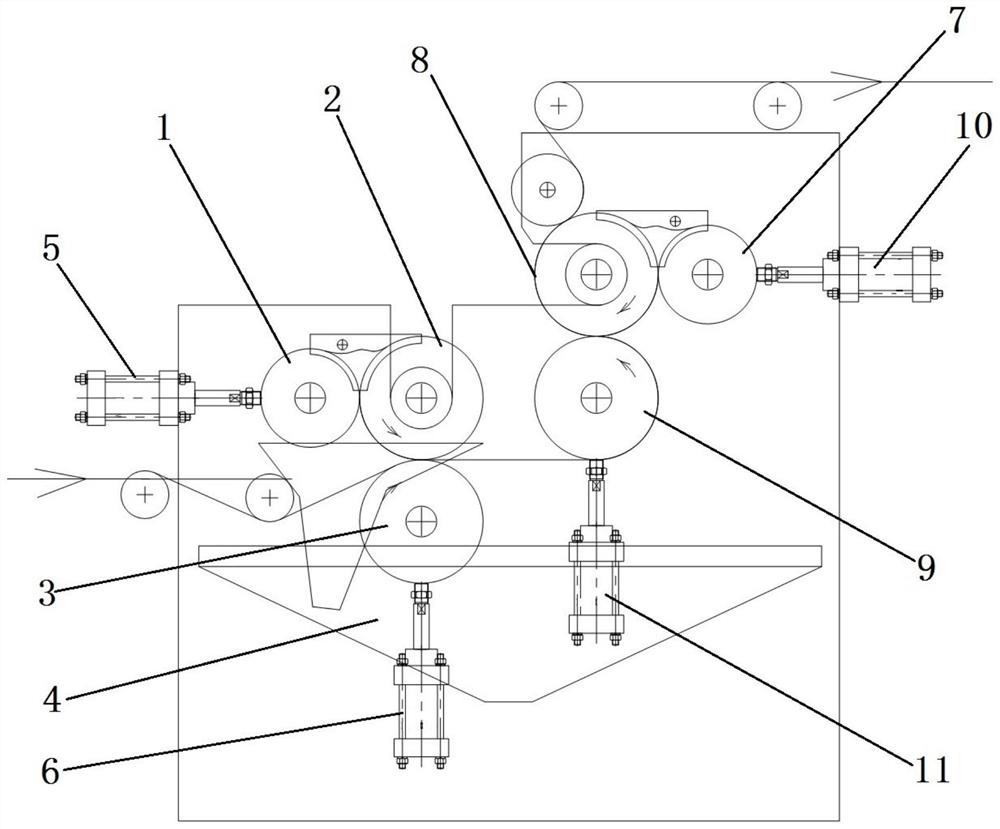

[0131] see Figure 2 to Figure 4 , Figure 11 to Figure 13 , the second implementation provides a stacking dyeing equipment applied to the stacking dyeing method, which specifically includes:

[0132] Cloth sending device 12, first rolling device 13, second rolling device 14, coiling device 15, post-processing device, finished product collecting device;

[0133] The cloth sending device 12, the first rolling device 13, the second rolling device 14, the coiling device 15, the post-processing device, and the finished product collecting device are arranged in sequence.

[0134] Further, the first rolling device 13 is a uniform rolling car, the second rolling device 14 is a quantitative coating rolling device, and the quantitative coating rolling device is single-sided, double-sided rotary screen printing and Rolling device or single-sided, double-sided coating and rolling device transferred by anilox roller or inner injection coating roller single-sided, double-sided coating an...

Embodiment 3

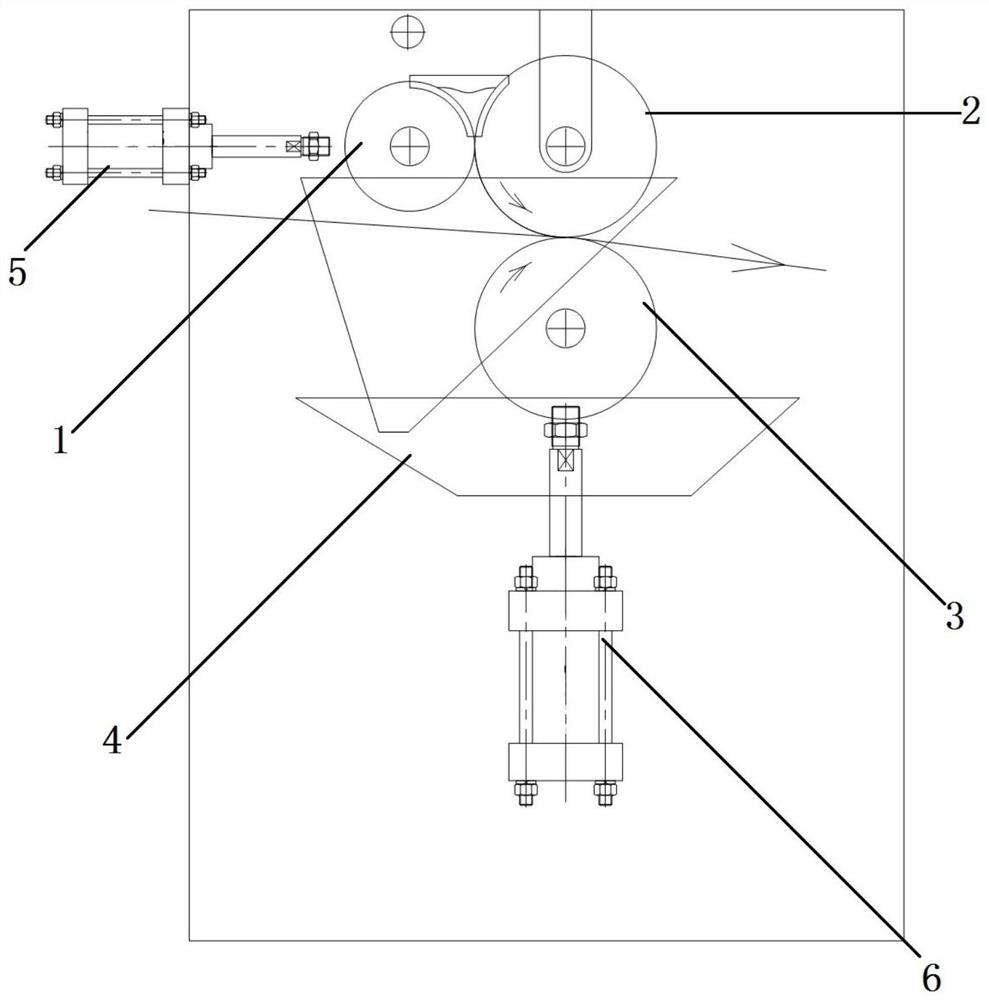

[0170] see Figure 5 to Figure 7 In the present embodiment, the quantitative coating rolling device (the second rolling device 14) is improved on the basis of the second embodiment, and the quantitative coating rolling device is a single-side and double-side coating And rolling device, it specifically includes:

[0171] Pipeline and inner injection type coating roller 31, the surface of said inner injection type coating roller 31 is provided with a plurality of water-permeable micropores;

[0172] The pipeline is connected with a pump 32, and the pump 32 pumps the auxiliary agent solution from the bucket of the second rolling device 14 into the inner chamber of the inner injection type coating roller 31, and the pump The pump 32 is a chemical pump or a diaphragm pump or a pneumatic pressure tank. Preferably, the pump 32 is a pump with an adjustable flow rate. By adjusting the flow rate of the pump, the output of the inner injection coating roller 31 to the cloth can be adjust...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com