Coal mining machine accurate positioning system and method based on acoustic array

A technology for precise positioning and shearer, applied in positioning, radio wave measurement system, measurement device and other directions, can solve problems such as failure to achieve shearer measurement and discontinuous monitor deployment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

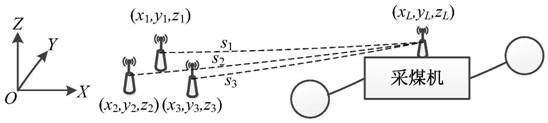

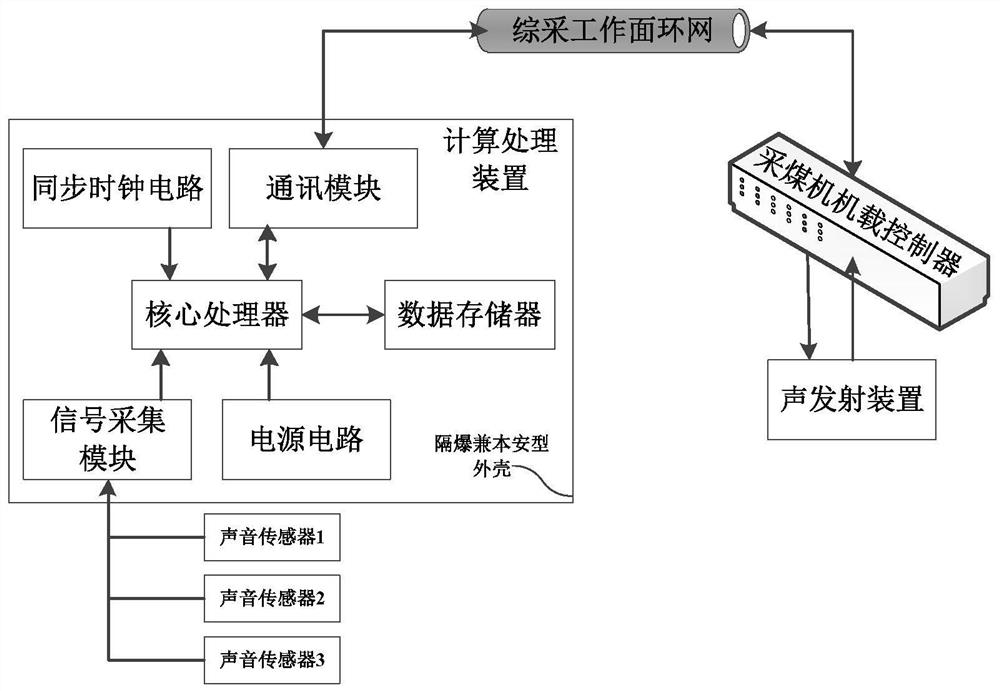

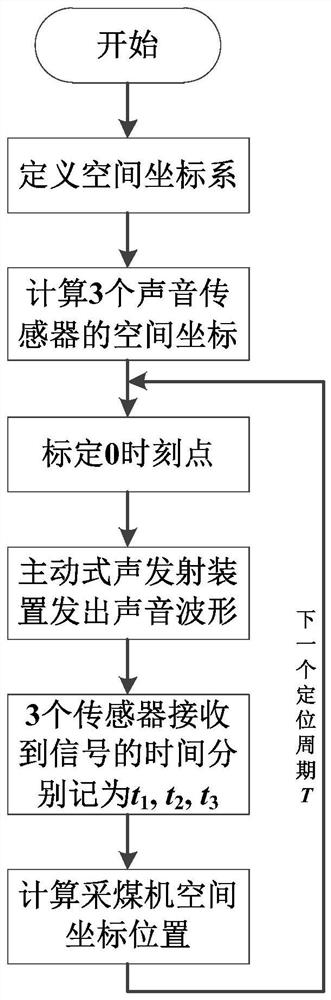

[0035] An accurate positioning system for a shearer based on an acoustic array of the present invention includes a fully-mechanized mining face shearer connected to the ring network of a fully-mechanized mining face through a communication module for mutual communication, a shearer airborne controller, and an on-board controller installed in the The active acoustic emission device on the shearer, the sound sensor array installed at the end of the air inlet side of the fully mechanized mining face, and the computing processing device used in conjunction with the sound sensor array.

[0036] The active acoustic emission device is connected to the onboard controller of the coal mining machine and connected to the ring network of the fully mechanized mining face; the onboard controller of the coal mining machine is used to give the active acoustic emission device a command to control it to emit a sound signal of a specified waveform. Further, the active acoustic emission device is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com