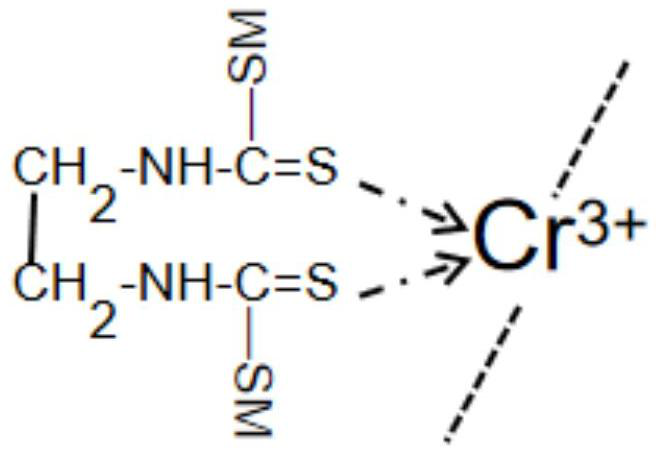

Recapture agent, preparation method and method for treating trivalent chromium in electroplating wastewater

A technology for electroplating wastewater and trivalent chromium, which is applied in the fields of metallurgical wastewater treatment, water/sewage treatment, chemical instruments and methods, etc. It can solve the problems of poor pertinence, poor electroplating wastewater treatment effect, and inability to meet standards in one-time treatment. , to achieve the effect of cost reduction, good treatment effect and strong treatment pertinence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] A 500g small airtight reactor with temperature control is used to prepare a recapture agent for trivalent chromium ions in electroplating wastewater:

[0040] 1.1 Raw materials, the amount of raw materials is shown in Table 1 below:

[0041] Table 1 Embodiment 1 raw material list:

[0042]

[0043] 1.2 Preparation method, comprising the following steps:

[0044] (1) Alcohol water is mixed with mass concentration and is the alcohol solution of 40%; Hydroxide water is configured with mass concentration and is the hydroxide solution of 25%;

[0045] (2) Add hexamethylenediamine and the alcohol solution prepared in step (1) into the reaction vessel at a room temperature of 25°C, and mix and stir for 18 minutes to obtain a mixed solution A;

[0046] (3) The temperature of the mixed solution A in the reaction vessel was lowered to 5°C, and carbon disulfide was added dropwise to the reaction vessel at a constant speed under stirring, and the dropwise addition was complete...

Embodiment 2

[0051] A 500g small airtight reactor with temperature control is used to prepare a recapture agent for trivalent chromium ions in electroplating wastewater:

[0052] 2.1 Raw materials, the amount of raw materials is shown in Table 2 below:

[0053] Table 2 Embodiment 2 raw material table:

[0054]

[0055] 2.2 Preparation method, comprising the following steps:

[0056] (1) Alcohol water is mixed with mass concentration and is the alcohol solution of 60%; Hydroxide water is configured with mass concentration and is the hydroxide solution of 15%;

[0057](2) Add hexamethylenediamine and the alcohol solution prepared in step (1) into the reaction vessel at a room temperature of 25°C, and mix and stir for 15 minutes to obtain a mixed solution A;

[0058] (3) The temperature of the mixed solution A in the reaction vessel was lowered to 10°C, and carbon disulfide was added dropwise to the reaction vessel at a constant speed under stirring, and the dropwise addition was complet...

Embodiment 3

[0063] A 500g small airtight reactor with temperature control is used to prepare a recapture agent for trivalent chromium ions in electroplating wastewater:

[0064] 3.1 Raw materials, the amount of raw materials is shown in Table 3 below:

[0065] Table 3 Embodiment 3 raw material table:

[0066]

[0067] 3.2 Preparation method, comprising the following steps:

[0068] (1) Alcohol water is mixed with mass concentration and is the alcohol solution of 20%; Hydroxide water is configured with mass concentration and is the hydroxide solution of 40%;

[0069] (2) At room temperature, add hexamethylenediamine and the alcohol solution prepared in step (1) into the reaction vessel, and mix and stir for 18 minutes to obtain mixed solution A;

[0070] (3) Lower the temperature of the mixed solution A in the reaction vessel to 7°C, and add carbon disulfide dropwise to the reaction vessel at a constant speed under stirring; after the dropwise addition, keep the temperature at 7°C and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com