Functional coating with mosquito repelling and heat dissipation effects and preparation method thereof

A heat dissipation effect and functional technology, applied in coatings, anti-corrosion coatings, epoxy resin coatings, etc., can solve hidden dangers, cause fires, skin allergies and other problems, achieve excellent insulation performance and heat dissipation effect, prolong service life, and stability excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

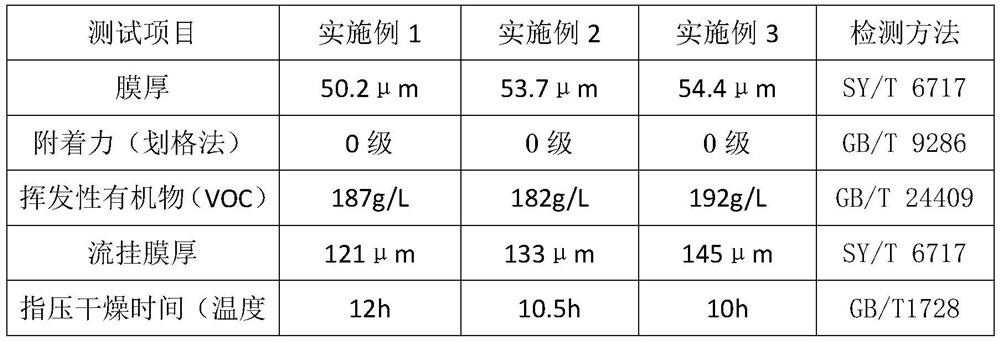

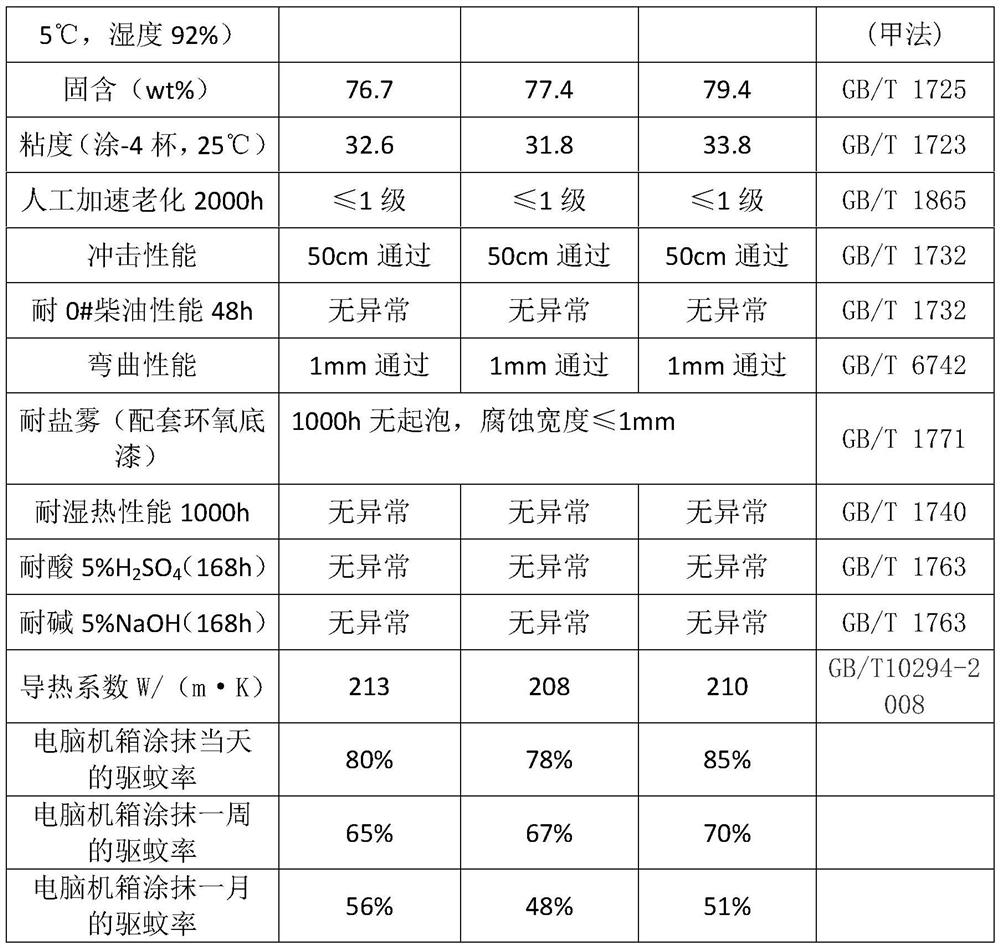

Examples

Embodiment 1

[0024] The functional coating of this embodiment with both mosquito repellent and heat dissipation effects is mixed with the following components: 20 parts by weight of epoxy resin; 3 parts by weight of mosquito repellent essential oil; 3 parts by weight of hydroxylated diatomaceous earth and 0.1 weight of carbon fiber Parts, 1.5 parts by weight of alumina, 0.5 parts by weight of iron oxide, 2 parts by weight of modified aromatic amine curing agent, 0.1 parts by weight of dispersant, 0.75 parts by weight of leveling agent, 1 part by weight of defoaming agent, 0.6 parts by weight of anti-settling agent And 2 parts by weight of organic solvent.

[0025] The preparation method of the functional coating with both repellent and heat dissipation effects in this embodiment includes the following steps:

[0026] (1) Preparation of traditional Chinese medicine extract: place the powder obtained by pulverizing the raw materials of traditional Chinese medicine in the extraction kettle, and th...

Embodiment 2

[0030] The functional coating of this embodiment with both repellent and heat dissipation effects is mixed with the following components: 25 parts by weight of epoxy resin; 6 parts by weight of mosquito repellent essential oil; 3.5 parts by weight of hydroxylated diatomaceous earth and 0.2 parts by weight of carbon fiber Parts, 2 parts by weight of alumina, 0.7 parts by weight of iron oxide, 3 parts by weight of modified aromatic amine curing agent, 0.15 parts by weight of dispersant, 1.3 parts by weight of leveling agent, 1.5 parts by weight of defoamer, 1.1 parts by weight of anti-settling agent And 10 parts by weight of organic solvent.

[0031] The method for preparing the functional coating with both repellent and heat dissipation effects in this embodiment includes the following steps:

[0032] (1) Preparation of traditional Chinese medicine extract: place the powder obtained by pulverizing the raw materials of traditional Chinese medicine in the extraction kettle, and then p...

Embodiment 3

[0036] The functional coating of this embodiment with both mosquito repellent and heat dissipation effects is mixed with the following components: 23 parts by weight of epoxy resin; 3 parts by weight of mosquito repellent essential oil; 3 parts by weight of hydroxylated diatomaceous earth and 0.1 weight of carbon fiber Parts, 1.5 parts by weight of alumina, 0.5 parts by weight of iron oxide, 2.5 parts by weight of modified aromatic amine curing agent, 0.15 parts by weight of dispersant, 1.1 parts by weight of leveling agent, 1 part by weight of defoaming agent, and 0.6 part by weight of anti-settling agent And 8 parts by weight of organic solvent.

[0037] The method for preparing the functional coating with both repellent and heat dissipation effects in this embodiment includes the following steps:

[0038] (1) Preparation of traditional Chinese medicine extract: place the powder obtained by pulverizing the raw materials of traditional Chinese medicine in the extraction kettle, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com