Polycrystalline silicon wafer surface texturing device based on ferromagnetic abrasion technology

A polysilicon wafer and abrasion technology, which is applied in crystal growth, semiconductor/solid-state device manufacturing, electrical components, etc., can solve the problems of reducing the utilization rate of silicon and not being easy to reuse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

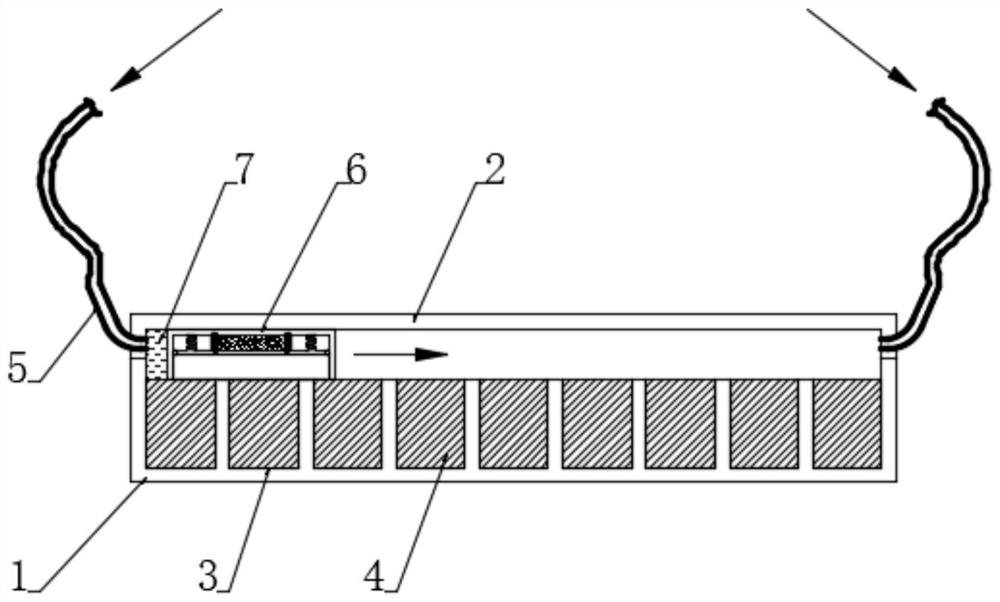

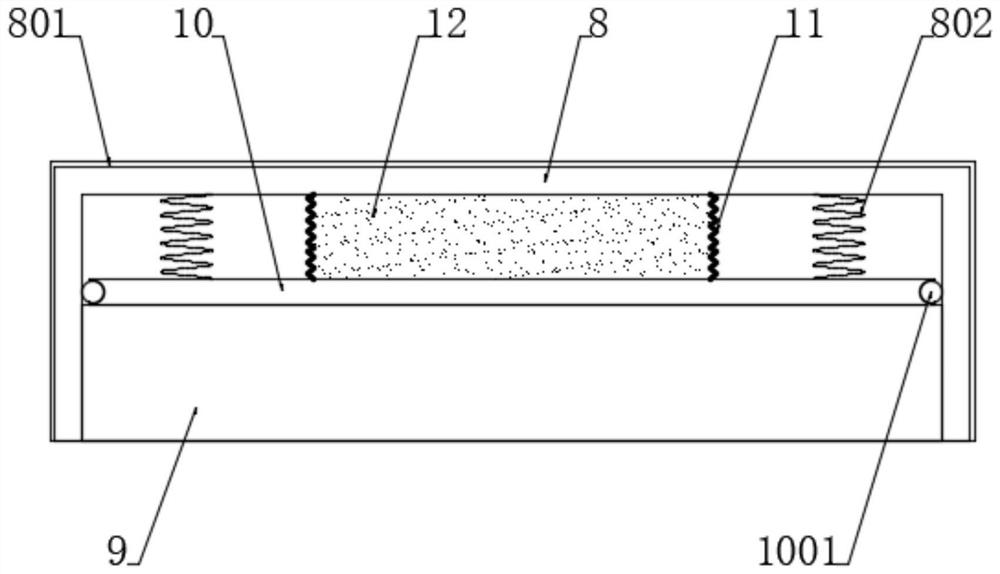

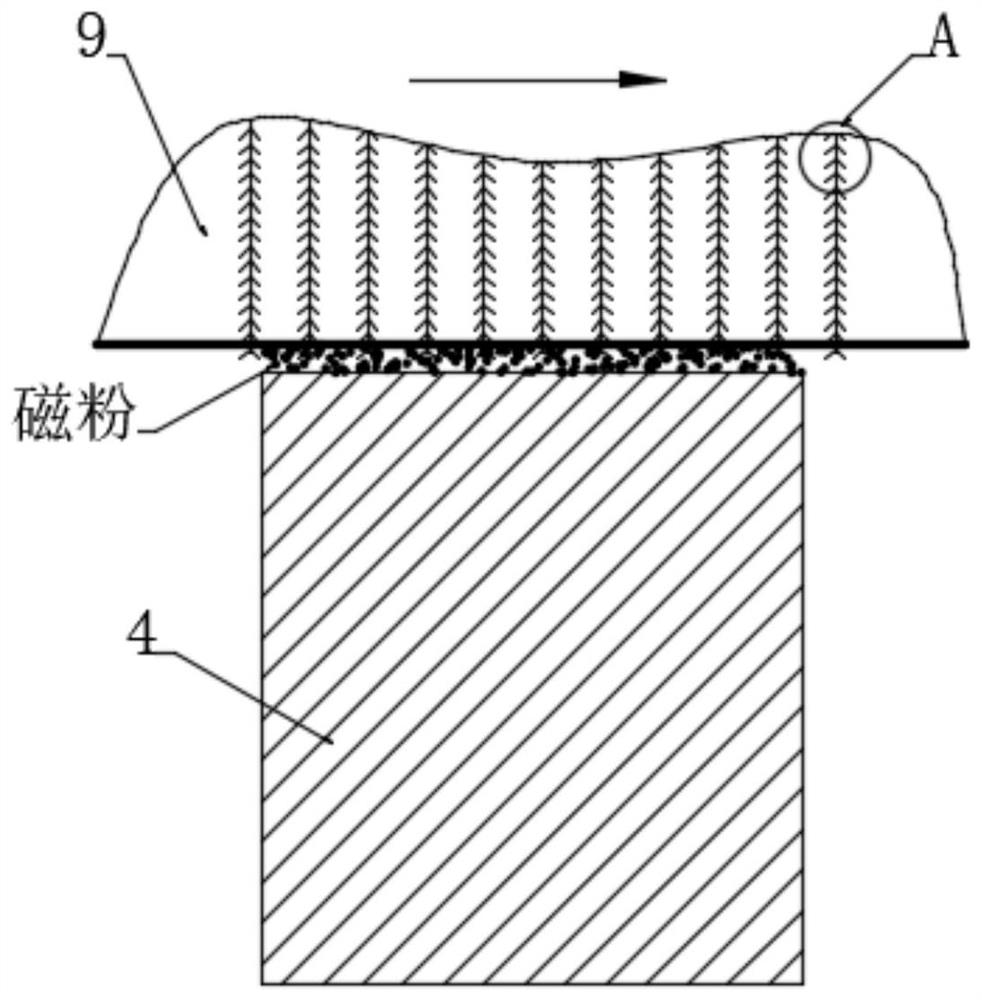

[0043] see Figure 1-2 , a surface texturing device for polycrystalline silicon wafers based on ferromagnetic wear technology, comprising a texturing storage box, the texturing storage box includes a texturing bottom box 1, the top end of the texturing bottom box 1 is clamped with a texturing top cover 2, the texturing The inner bottom of the bottom box 1 is excavated with a plurality of evenly distributed silicon chip storage tanks 3. The silicon chip storage tanks 3 are provided with polycrystalline silicon chips 4. The left and right ends of the textured top cover 2 are embedded with transmission conduits 5, two The outer ends of the transmission conduit 5 are connected with hydraulic pumps, through which the passivation solvent 7 is continuously input into the texturing storage box, the transmission conduit 5 and the texturing storage box are connected to each other, and a movable grinding iron block 6 is arranged in the texturing storage box and passivation solvent 7, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com