Composite catalyst for metal-air battery cathode and preparation method thereof

A metal-air battery and composite catalyst technology, which is applied to battery electrodes, circuits, electrical components, etc., can solve the problems of high preparation cost, cumbersome process, and inability to meet large-scale production, and achieve enhanced catalytic activity, high stability, and preparation The effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

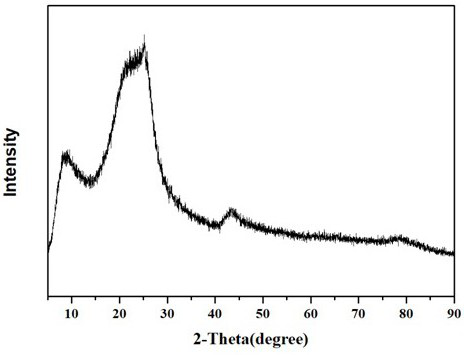

[0034] Weigh 0.2g Vulcan-72XC and 0.05g carbon nanotubes (mass ratio 4:1), add the two to absolute ethanol, stir, ultrasonicate, dry, and the mixture is named V-CNT. Weigh 0.25g V-CNT and 1g urea (mass ratio 1:4), add the two to absolute ethanol and stir, ultrasonicate, dry, and the mixture is named V-CNT-N. Then the dried V-CNT-N was put into a tube furnace and heated to 600 °C for 3 h at a heating rate of 5 °C / min under nitrogen. Finally, the reaction product was ground and dried to obtain the final product, that is, a nitrogen-doped Vulcan-72XC / carbon nanotube material, named V-CNT-N-600°C.

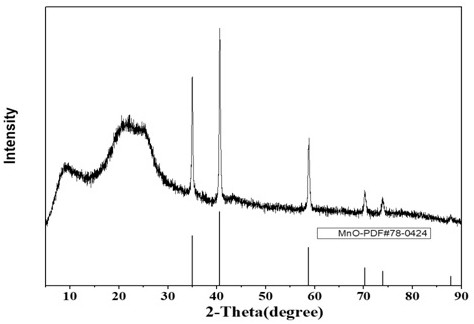

[0035] Weigh 0.5g V-CNT-N-600℃ and 0.5g manganese acetate tetrahydrate (mass ratio 1:1), add absolute ethanol to stir, ultrasonicate, and dry. Then the dried mixture was put into a tube furnace and heated to 280 °C for 3 h at a heating rate of 5 °C / min under nitrogen. Finally, the reaction product is ground and dried to obtain the final product, that is, a nitrogen-doped Vulcan-72XC / ...

Embodiment 2

[0038] Weigh 0.45g Vulcan-72XC and 0.05g carbon nanotubes (mass ratio 9:1), add the two to absolute ethanol and stir, ultrasonicate, dry, and the mixture is named V-CNT. Weigh 0.25g V-CNT and 1g urea (mass ratio 1:4), add the two to absolute ethanol and stir, ultrasonicate, dry, and the mixture is named V-CNT-N. Then the dried V-CNT-N was put into a tube furnace and heated to 550 °C for 5 h at a heating rate of 5 °C / min under nitrogen. Finally, the reaction product was ground and dried to obtain the final product, that is, a nitrogen-doped Vulcan-72XC / carbon nanotube material, named V-CNT-N-550°C.

[0039]Weigh 0.5g V-CNT-N-550℃ and 0.25g manganese acetate tetrahydrate (mass ratio 2:1), add the two to absolute ethanol, stir, ultrasonicate, and dry. Then the dried mixture was put into a tube furnace and heated to 300 °C for 5 h at a heating rate of 5 °C / min under nitrogen. Finally, the reaction product is ground and dried to obtain the final product, that is, a nitrogen-doped...

Embodiment 3

[0042] Weigh 0.45g Vulcan-72XC and 0.05g carbon nanotubes (mass ratio 9:1), add the two to absolute ethanol and stir, ultrasonicate, dry, and the mixture is named V-CNT. Weigh 0.25g V-CNT and 0.75g melamine (mass ratio 1:3), add the two to absolute ethanol and stir, ultrasonicate, dry, and the mixture is named V-CNT-N. Then the dried V-CNT-N was put into a tube furnace and heated to 580 °C for 4 h at a heating rate of 5 °C / min under nitrogen. Finally, the reaction product was ground and dried to obtain the final product, that is, a nitrogen-doped Vulcan-72XC / carbon nanotube material named V-CNT-N-580°C.

[0043] Weigh 0.5g V-CNT-N-550℃ and 0.5g manganese acetate tetrahydrate (mass ratio 1:1), add absolute ethanol to stir, ultrasonicate, and dry. Then the dried mixture was put into a tube furnace and heated to 250 °C for 4 h at a heating rate of 5 °C / min under nitrogen. Finally, the reaction product is ground and dried to obtain the final product, that is, a nitrogen-doped Vu...

PUM

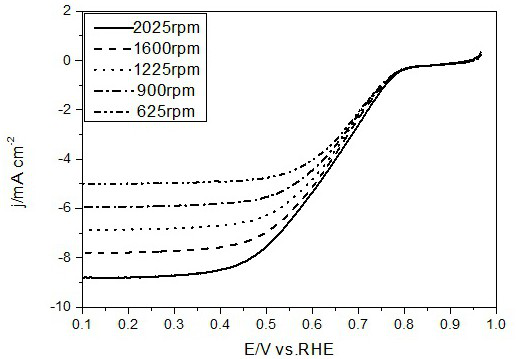

| Property | Measurement | Unit |

|---|---|---|

| current density | aaaaa | aaaaa |

| current density | aaaaa | aaaaa |

| current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com