Composite manufacturing method for seawater pump impeller nut

An impeller nut and a manufacturing method technology, applied in the field of sea water pumps, can solve the problems of the impeller nut being easy to corrode, susceptible to corrosion failure, thread wear, etc., so as to improve the toughness and corrosion resistance, the process plan is simple and easy to understand, and the service life is improved. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

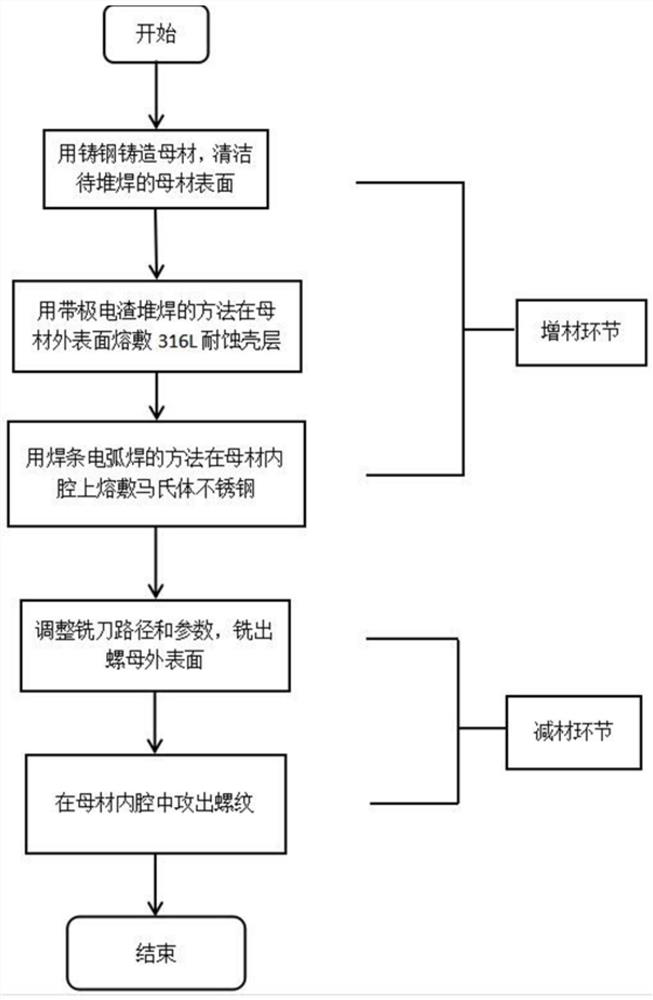

[0032] A composite manufacturing method for a seawater pump impeller nut, comprising the following steps:

[0033] (1) Cast the base metal to be surfacing with cast steel, and clean the surface of the base metal;

[0034] (2) Use the surfacing material provided by the invention to deposit a layer of 316L stainless steel on the outer surface of the base metal

[0035] (3) cladding martensitic stainless steel on the inner cavity wall of the base metal with the wear-resistant electrode provided by the invention;

[0036] (4) According to the shape and surface material characteristics of the finished nut, set the moving path and process parameters of the milling cutter;

[0037] (5) Processing and milling out the outer surface of the nut;

[0038] (6) Tapping threads on the inner cavity of the base metal;

[0039] (7) Further processing as required, such as fine milling, polishing, etc.

[0040] Further, the process of cleaning the surface of the parent material in step (1) ma...

Embodiment 2

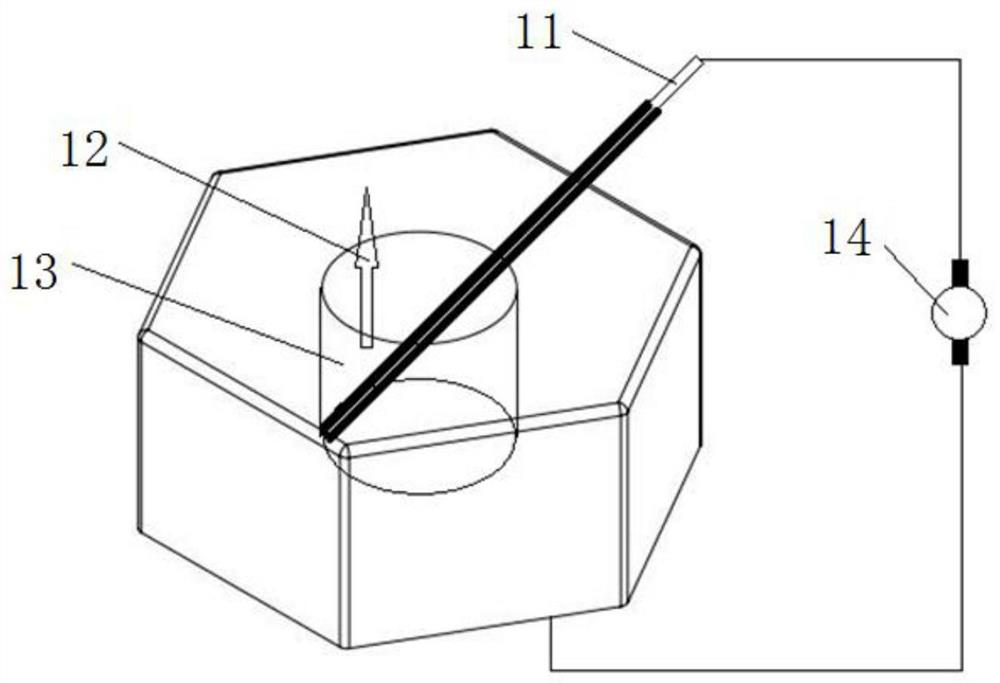

[0050] In order to get as Figure 4 The hexagonal prism-shaped impeller nut shown is manufactured using the composite manufacturing method provided by the present invention, and the process is as follows:

[0051] (1) Cast the base metal to be surfacing with cast steel, and clean the surface of the base metal. In this embodiment, ZG275-485H is preferably used as the casting material. The method of cleaning the surface of the base material includes trimming the flow channel, sanding to remove scale and sand inclusions, cleaning, dust removal and decontamination.

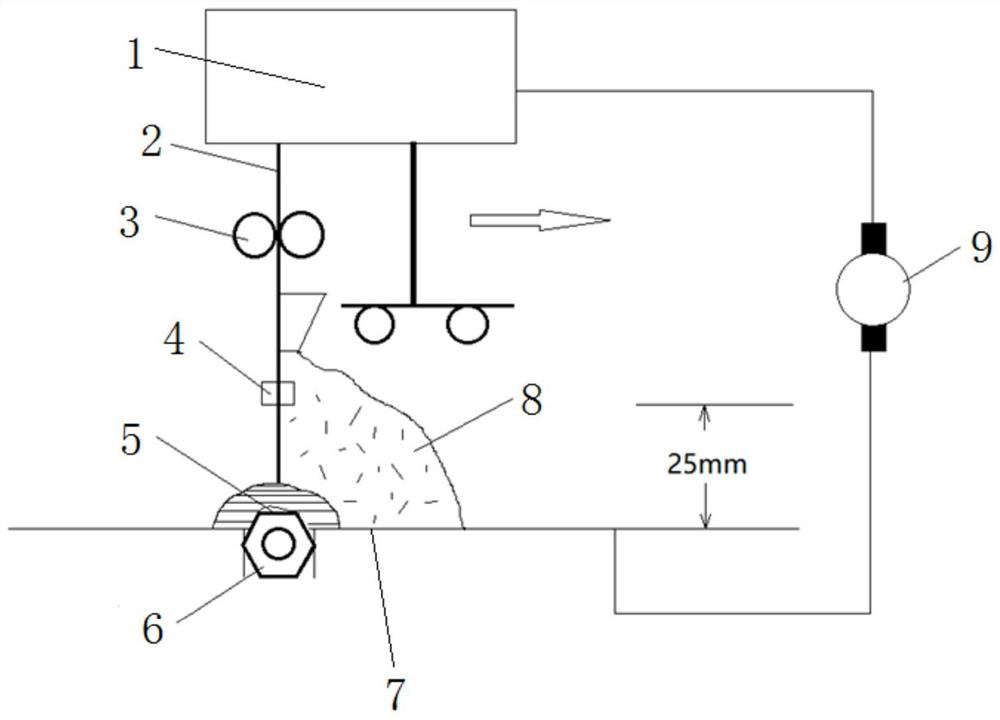

[0052] (2) Use the surfacing material provided by the invention to deposit the corrosion-resistant shell on the outer surface of the base metal by means of strip electroslag surfacing. The surfacing material is composed of welding strip and flux. The welding strip is 316L stainless steel with a cross-sectional size of 10mm×0.5mm, and the preferred preparation method of the flux is as follows.

[0053] Flux prepara...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com