Magnetic powder wet-type adding system and method

A magnetic powder, wet technology, applied in chemical instruments and methods, magnetic field/electric field water/sewage treatment, flocculation/sedimentation water/sewage treatment, etc. Implementation and other issues to achieve the effect of saving time, reducing floor space and saving costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in further detail below in conjunction with the accompanying drawings.

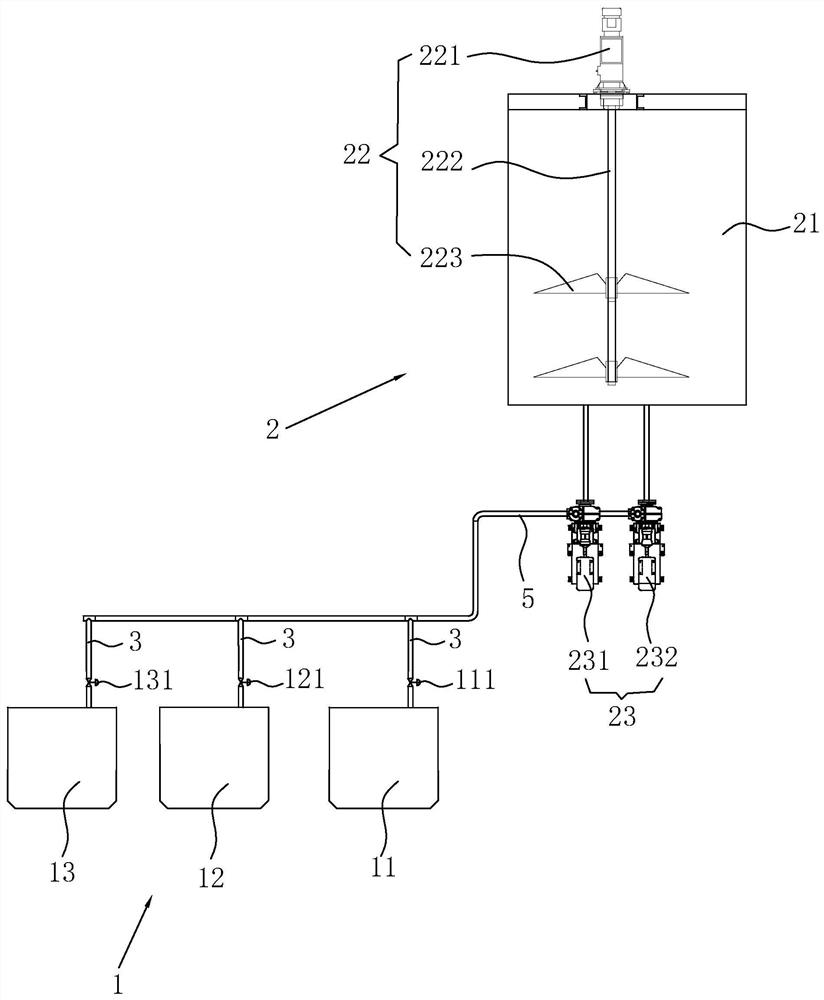

[0034] refer to figure 1 , is a magnetic powder wet adding system disclosed in the present invention, including a magnetic powder premixing unit 2 for uniformly mixing magnetic powder and water, and the magnetic powder premixing unit 2 communicates with each sewage treatment system 1 through a pipeline 3 .

[0035] Firstly, the magnetic powder and water are uniformly mixed in the magnetic powder premixing unit 2 to obtain the magnetic powder mixed liquid, and then transported to each sewage treatment system 1 through the pipeline 3. One magnetic powder premixing unit 2 can be applied to multiple sewage treatment systems 1, greatly The floor area is greatly reduced, the cost is saved, and the magnetic powder mixture is added to each sewage treatment system 1 instead of directly adding magnetic powder, which can accelerate the mixing efficiency of magnetic powd...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com