High-volume phosphogypsum composite stable roadbed material and preparation method thereof

A technology of roadbed material and phosphogypsum, applied in the field of highway construction materials, can solve the problems of low early strength of concrete, high rigidity of road matrix, low content of phosphogypsum, etc., and achieves the absorption of industrial solid waste, the stable development of strength, and the consumption of phosphogypsum. big effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

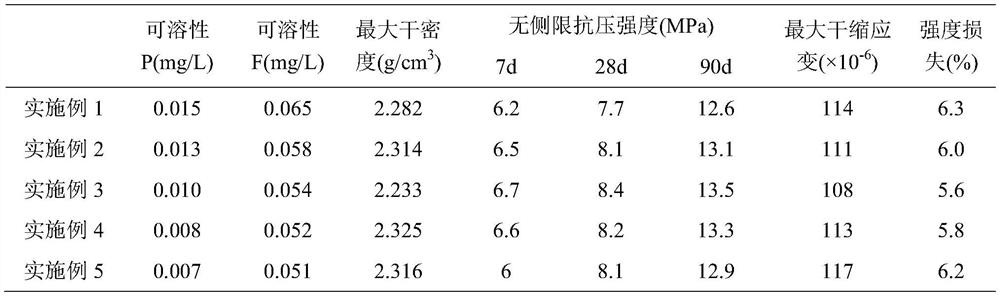

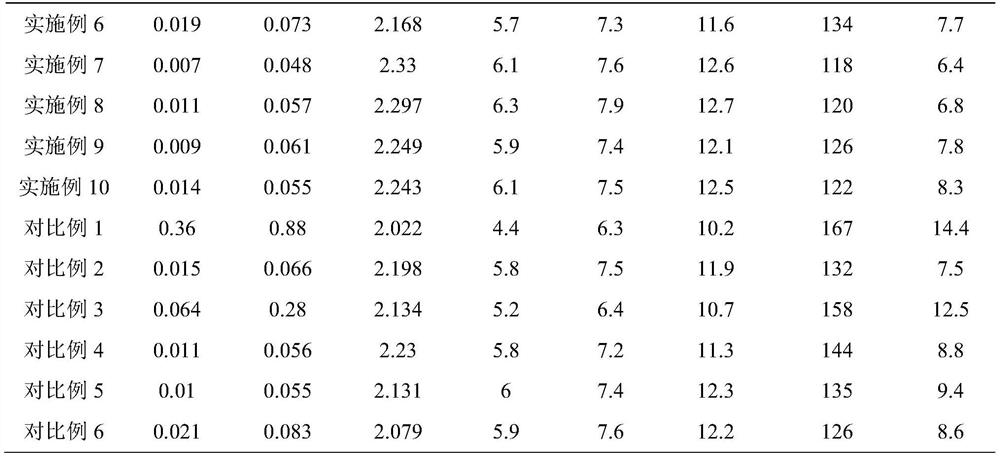

Examples

Embodiment 1

[0033] A large-volume phosphogypsum composite stable roadbed material, comprising: 91% phosphogypsum, 3.5% curing agent, 3% curing accelerator and 2.5% water;

[0034] The curing agent includes Portland cement, ultrafine steel slag powder and blast furnace slag powder, the mass ratio of the Portland cement, ultrafine steel slag powder and blast furnace slag powder is 3:3:8; the ultrafine steel slag powder And the particle size of blast furnace slag powder is 100-200 μm.

[0035] The curing accelerator includes water glass, inositol and cationic styrene-acrylic emulsion (purchased from Linyi Yoshida New Building Materials Co., Ltd.), and the mass ratio of the water glass, inositol and cationic styrene-acrylic emulsion is 7:0.8:5.

[0036] The preparation method of the above-mentioned large-volume phosphogypsum composite stable roadbed material comprises the following steps:

[0037] S1. Grind the pretreated phosphogypsum until the specific surface area is not less than 1000m ...

Embodiment 2

[0041] Example 2 is basically the same as Example 1, except that the proportion of curing accelerator is different: the mass ratio of water glass, inositol and cationic styrene-acrylic emulsion is 7:1.2:8.

Embodiment 3

[0043] Example 3 is basically the same as Example 1, except that the proportion of curing accelerator is different: the mass ratio of water glass, inositol and cationic styrene-acrylic emulsion is 7:1.4:12.5.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com