High-melt-index polypropylene and preparation process thereof

A technology of polypropylene and high melting index, applied in the chemical industry, can solve the problems of uneven dispersion, insufficient reaction, interference of other components, etc., and achieve the effects of low melting temperature, avoiding reaction imbalance and high melting index

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

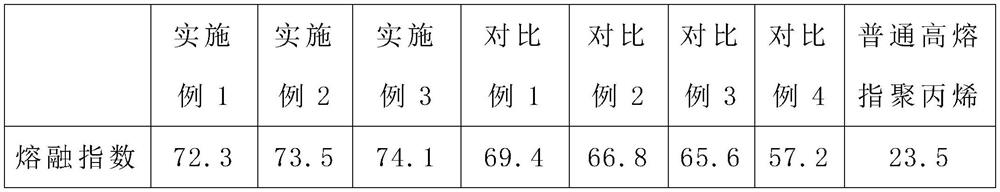

Examples

Embodiment 1

[0036] Mix 73.3 parts of polypropylene with molecular sieves, stir evenly, and knead at 160°C for 7 minutes to obtain product A; take 0.8 parts of plasticizer, add 0.05 parts of erucamide and 10 parts of polyethylene wax and mix evenly. For bis (2-ethylhexyl) phthalate, mixture B is obtained;

[0037] Take the product A and put it in the reaction kettle and seal it, add the mixture B and mix evenly, add 0.15 parts of organic peroxide and stir evenly, the organic peroxide is di-tert-butyl peroxide, heat to 170°C, and stir at a speed of 180r / min 30min;

[0038] Add 0.3 part of polymerization inhibitor, 0.1 part of antioxidant and shear at 600r / min for 45min. The polymerization inhibitor is p-hydroxyanisole, and the antioxidant is dibutyl hydroxytoluene and 2-tert-butyl p-phenyl Diphenol, and irradiated, the irradiation dose is 30kGy;

[0039] Add 0.001 part of stearate-dibasic acid complex and mix evenly. The stearate in the stearate-dibasic acid compound is zinc stearate, and...

Embodiment 2

[0041] Mix 80.94 parts of polypropylene with molecular sieves, stir evenly, and knead at 165°C for 11 minutes to obtain product A; take 1.4 parts of plasticizer, add 0.17 parts of erucamide and 15 parts of polyethylene wax and mix evenly. For dibutyl phthalate, mixture B is obtained;

[0042]Take the product A and put it in the reaction kettle and seal it, add the mixture B and mix evenly, add 1.5 parts of organic peroxide and stir evenly, the organic peroxide is dicumyl peroxide, heat to 185°C, and stir at a speed of 210r / min 45min;

[0043] Add 0.4 part of polymerization inhibitor, 0.4 part of antioxidant and shear 52min under the rotating speed of 750r / min, polymerization inhibitor is p-methoxyphenol, antioxidant is dibutyl hydroxytoluene and 2-tert-butyl p-phenyl Diphenol, and irradiated, the irradiation dose is 35kGy;

[0044] Add 0.003 parts of stearate-dibasic acid complex and mix evenly. The stearate in the stearate-dibasic acid compound is calcium stearate, and the ...

Embodiment 3

[0046] Mix 88.58 parts of polypropylene with molecular sieves, stir evenly, and knead at 170°C for 15 minutes to obtain product A; take 2 parts of plasticizer, add 0.3 parts of erucamide and 20 parts of polyethylene wax and mix evenly. For bis (2-ethylhexyl) phthalate, mixture B is obtained;

[0047] Take the product A and put it in the reaction kettle and seal it, add the mixture B and mix evenly, add 3 parts of organic peroxide and stir evenly, the organic peroxide is 2,5-dimethyl-2,5-bis(tert-butyl peroxy base) hexane, heated to 200°C, and stirred at a speed of 240r / min for 60min;

[0048] Add 0.5 parts of polymerization inhibitor, 0.8 parts of antioxidant and shear at 900r / min for 60min. The polymerization inhibitor is 2,5-di-tert-butylhydroquinone, and the antioxidant is dibutylhydroxytoluene and 2-tert-butylhydroquinone, and irradiated, the irradiation dose is 40kGy;

[0049] Add 0.005 parts of stearate-dibasic acid complex and mix evenly. The stearate in the stearate-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com