Method for preparing amino acid aqueous solution from dead chickens

An amino acid and aqueous solution technology, applied in the field of aquaculture, can solve the problems of inability to be widely used, high processing cost, harsh conditions, etc., and achieve the effects of significant environmental and economic benefits, high amino acid content, and short processing time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

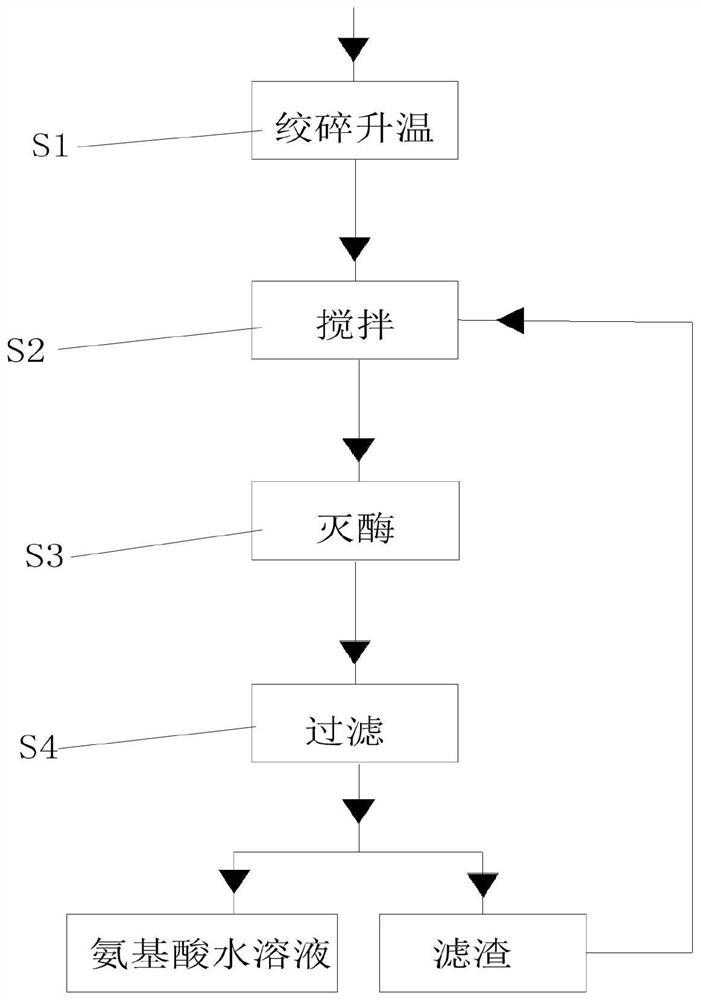

[0024] Such as figure 1 As shown in the process flow chart, at first the sick and dead chickens are crushed into a mixture of 2-5cm.

[0025] Add water into the mixture, the ratio of mixture and water is 1:3, stir and mix evenly.

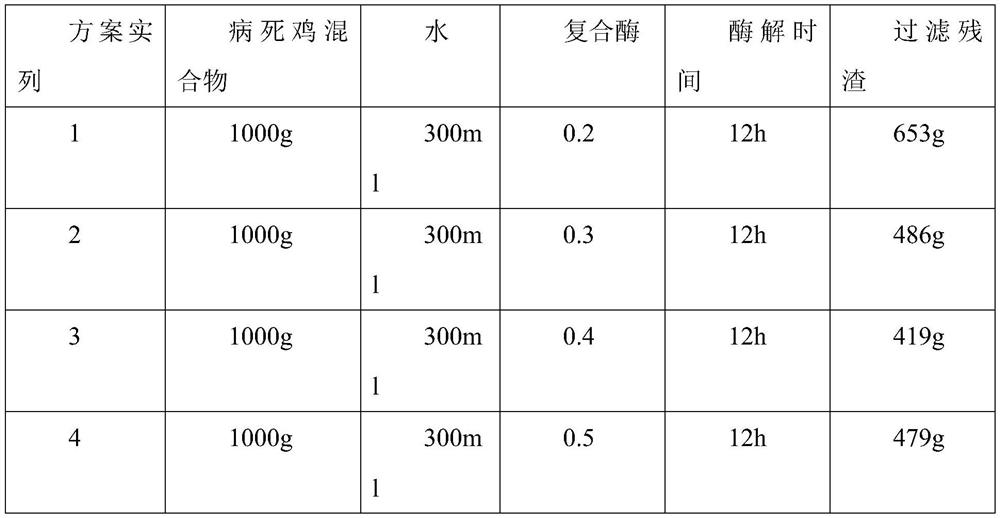

[0026] Then heat the mixed solution to 45°C, add 300,000 u / g of compound enzyme, add according to the weight ratio of the mixture and the enzyme at 0.2%, then stir and mix evenly, then enzymolyze, monitor the quality of the residue after enzymolysis for 12 hours, and obtain the enzyme solution product.

[0027] The filter residue is returned to the stirring device to be mixed with the newly added mixture and then processed again.

[0028] Heat the enzymatic hydrolysis product to 95°C and inactivate the enzyme for 15-20 minutes.

[0029] The above enzymatic hydrolysis solution was naturally cooled to room temperature to obtain an aqueous amino acid solution.

Embodiment 2

[0031] Such as figure 1 As shown in the process flow chart, at first the sick and dead chickens are crushed into a mixture of 2-5cm.

[0032] Add water into the mixture, the ratio of mixture and water is 1:3, stir and mix evenly.

[0033] Then heat the mixture to 45°C, add 300,000 u / g of compound enzyme, and add it according to the weight ratio of mixture and enzyme at 0.3%, then stir and mix evenly, enzymolyze for 12 hours, monitor the quality of the filtered residue, and obtain the enzymolyzed product .

[0034] The filter residue is returned to the stirring device to be mixed with the newly added mixture and then processed again.

[0035] Heat the enzymatic hydrolysis product to 95°C and inactivate the enzyme for 15-20 minutes.

[0036] The above enzymatic hydrolysis solution was naturally cooled to room temperature to obtain an aqueous amino acid solution.

Embodiment 3

[0038] Such as figure 1 As shown in the process flow chart, at first the sick and dead chickens are crushed into a mixture of 2-5cm.

[0039] Add water into the mixture, the ratio of mixture and water is 1:3, stir and mix evenly.

[0040] Then heat the mixed solution to 45°C, add 300,000 u / g of compound enzyme, add according to the weight ratio of the mixture and enzyme at 0.4%, then stir and mix evenly, enzymolyze for 12 hours, monitor the quality of the filtered residue, and obtain the enzymolyzed product .

[0041] The filter residue is returned to the stirring device to be mixed with the newly added mixture and then processed again.

[0042] Heat the enzymatic hydrolysis product to 95°C and inactivate the enzyme for 15-20 minutes.

[0043] The above enzymatic hydrolysis solution was naturally cooled to room temperature to obtain an aqueous amino acid solution.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com