Electroplating method based simple super-hydrophobic tube inner surface preparation device

A super-hydrophobic surface and a technology for preparing devices, which are applied in electrolytic components, electrolytic processes, cells, etc., can solve problems such as limited operation, low surface uniformity, and expensive equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] 1. Pre-treatment of pipe fittings: take a copper pipe with a length of 500mm and an inner diameter of 10mm as the pipe fitting to be plated, perform surface polishing, stain removal, and degreasing treatment, then activate for 30S, clean it with deionized water, and dry it to obtain the treated pipe. Workpiece; Activation Solution Components: HCL with a volume fraction of 10%.

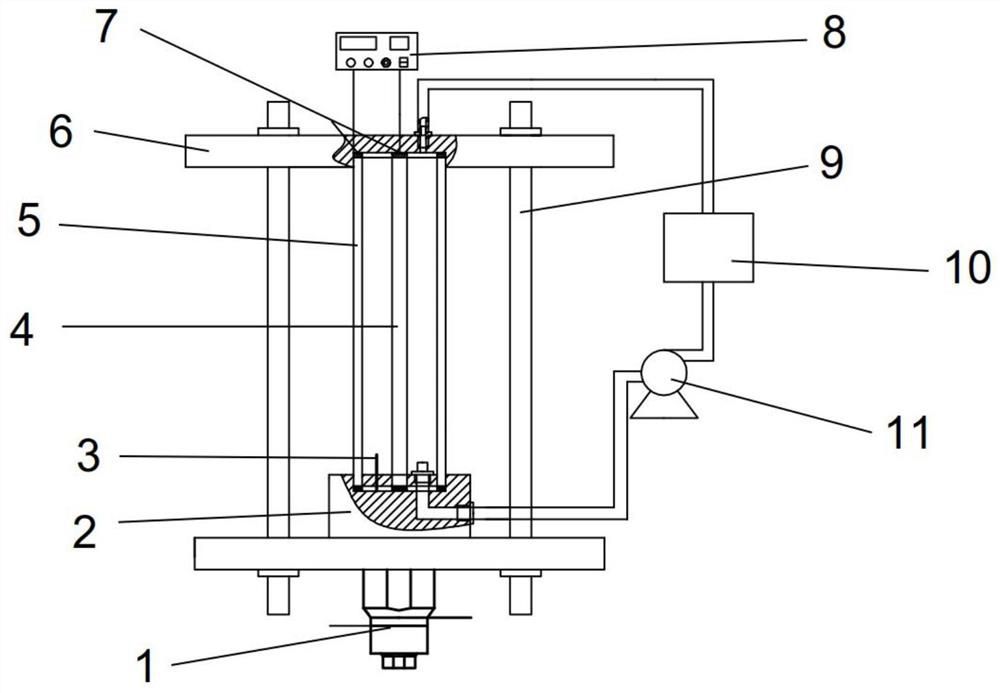

[0025] 2. Installation of pipe fittings: first install the pipe fitting 5 to be plated on the base 2, slowly move the electroplating anode 4 vertically down to the groove of the base 2, and then screw in the screw rod 9 to complete the sealing of the device.

[0026] 3. Electroplating: nickel rods are used as the electroplating anode 4, the workpiece after pretreatment is the cathode 5, the radial distance between the two poles is 4mm, electroplating is carried out in the basic electroplating solution, the distance between the electrodes is 2mm, the specific parameters of electrodeposition: pump ...

Embodiment 2

[0028] 1. Pre-treatment of pipe fittings: use Q235 steel pipes with a length of 500mm and an inner diameter of 10mm as the pipe fittings to be plated, perform surface polishing, stain removal, and degreasing treatment, then activate for one minute, clean them with deionized water, and dry them to obtain processed Workpiece; Activation solution composition: 0.07mol / L of H 2 SO 4 .

[0029] 2. Installation of pipe fittings: first install the pipe fitting 5 to be plated on the base 2, slowly move the electroplating anode 4 vertically down to the groove of the base 2, and then screw in the screw rod 9 to complete the sealing of the device.

[0030] 3. Electroplating: the copper tube is used as the electroplating anode 4, the workpiece after pretreatment is the cathode 5, and the radial distance between the two poles is 2mm. Electroplating is carried out in the basic electroplating solution, and the distance between the electrodes is 4mm. The specific parameters of electrodepositi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com