Ion sensor based on MXene electrodes and preparation method of ion sensor

An ion sensor and electrode technology, which is applied in the field of ion sensors based on MXene electrodes and their preparation, can solve the problems of complex and time-consuming preparation of ion sensor structures, and achieve the effects of simple structure, increased stability, and increased distance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

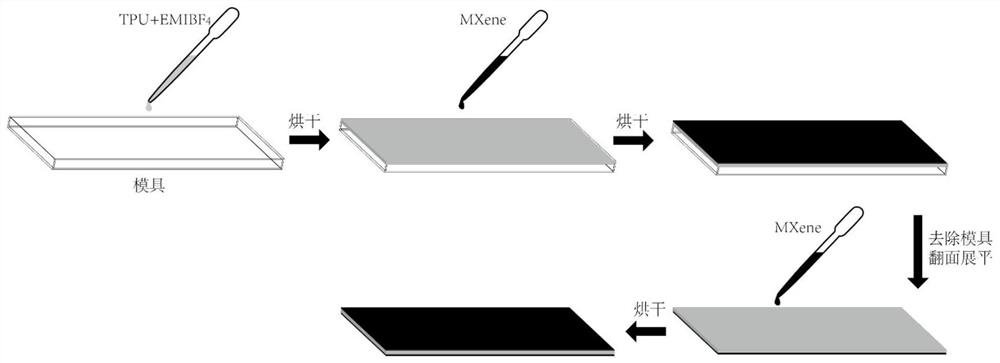

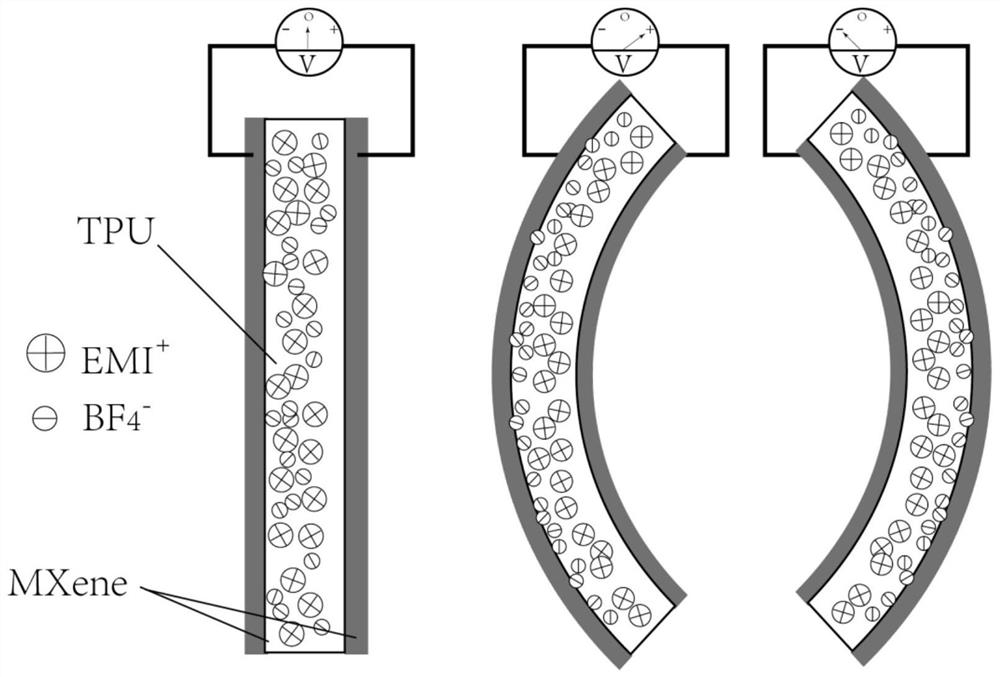

[0054] Preparation method of ion sensor based on MXene electrode

[0055] (1) Preparation of ionic polymer layer solution: 0.5g ionic liquid EMIBF 4 and 1.0 g of thermoplastic polyurethane (TPU) were added into 15 g of DMF, and stirred at 70° C. for 10 hours at a speed of 600 r / min, and the obtained TPU ionic liquid solution was the ionic polymer layer solution.

[0056] (2) Preparation of ionic polymer membrane: the area is 25*75mm 2 Place the glass sheet template horizontally in the heating box, and adjust the temperature in the heating box to 70°C. Then use a pipette gun to take out 1ml of the ionic polymer layer solution each time and drop it onto the glass slide for a total of 2 drops. Dry it in a heating box for 2 hours, and then take it out to prepare an ionomer membrane.

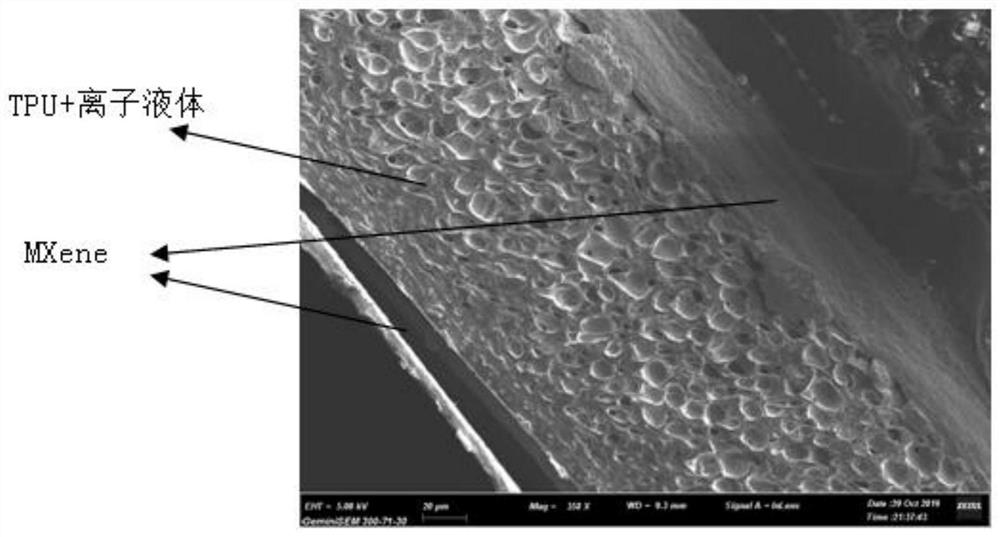

[0057] (3) Place the ionomer film on the glass plate horizontally on the heating platform, and adjust the temperature to 45°C. Then drop-coat 2ml of 10mg / ml MXene electrode solution on the surfac...

Embodiment 2

[0061] Preparation method of ion sensor based on MXene electrode

[0062] (1) Preparation of ionic polymer layer solution: 1 g of ionic liquid EMIBF 4 and 1.0 g of thermoplastic polyurethane (TPU) were added into 15 g of DMF, and stirred for 20 hours at 70° C. with a rotation speed of 600 r / min, and the obtained TPU ionic liquid solution was the ionic polymer layer solution.

[0063] (2) Preparation of ionic polymer membrane: the area is 25*75mm 2 Place the glass sheet template horizontally in the heating box, and adjust the temperature in the heating box to 70°C. Then use a pipette gun to take out 1ml of the ionic polymer layer solution each time and drop it onto the glass slide for a total of 3 times. Dry it in a heating box for 2 hours, and then take it out to prepare an ionomer membrane.

[0064] (3) Place the ionomer film on the glass plate horizontally on the heating platform, and adjust the temperature to 45°C. Then drop-coat 1ml of 5mg / ml MXene electrode solution o...

Embodiment 3

[0068] Preparation method of ion sensor based on MXene electrode

[0069] (1) Preparation of ionic polymer layer solution: 1 g of ionic liquid EMIBF 4 and 1.0 g of thermoplastic polyurethane (TPU) were added into 15 g of DMF, and stirred at 70° C. for 10 hours at a speed of 600 r / min, and the obtained TPU ionic liquid solution was the ionic polymer layer solution.

[0070] (2) Preparation of ionic polymer membrane: the area is 25*75mm 2 Place the glass sheet template horizontally in the heating box, and adjust the temperature in the heating box to 70°C. Then use a pipette gun to take out 3ml of ionomer layer solution each time and drop onto the glass slide. Dry it in a heating box for 2 hours, and then take it out to prepare an ionomer membrane.

[0071] (3) Place the ionomer film on the glass plate horizontally on the heating platform, and adjust the temperature to 45°C. Then drop-coat 2ml of 10mg / ml MXene electrode solution on the surface of the ionic polymer membrane an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com