Semiconductor device and forming method thereof

A technology of semiconductors and storage devices, which is applied in semiconductor devices, semiconductor/solid-state device manufacturing, transistors, etc., and can solve problems such as the inability to meet the resolution requirements or production process requirements for manufacturing micro-linewidth patterns

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0071] In order to enable those who are familiar with the technical field of the present invention to further understand the present invention, several preferred embodiments of the present invention are enumerated below, and in conjunction with the accompanying drawings, the constitutional content and intended achievement of the present invention are explained in detail. effect.

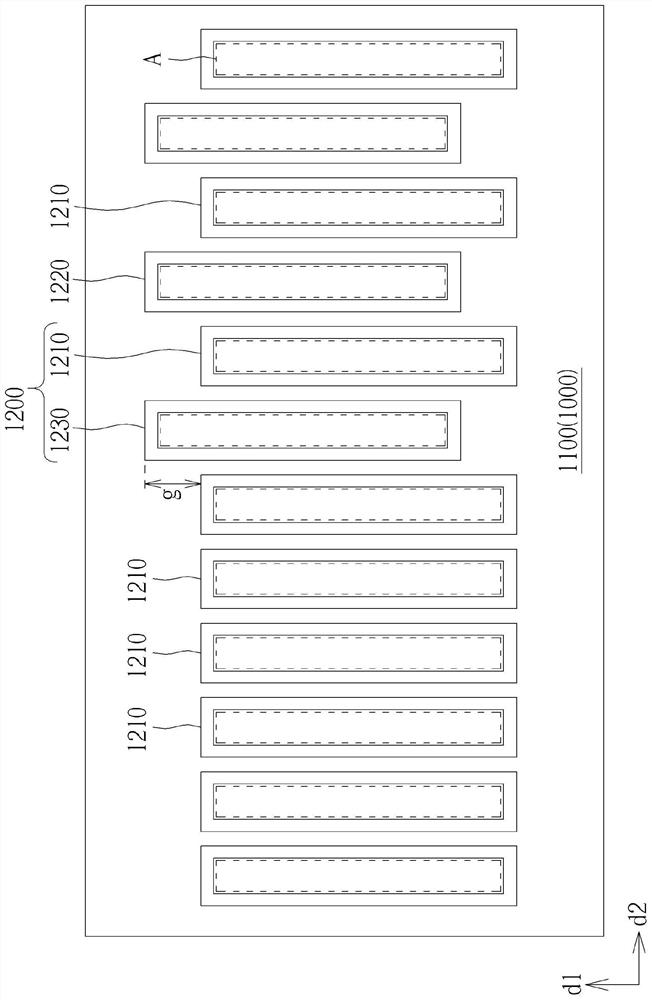

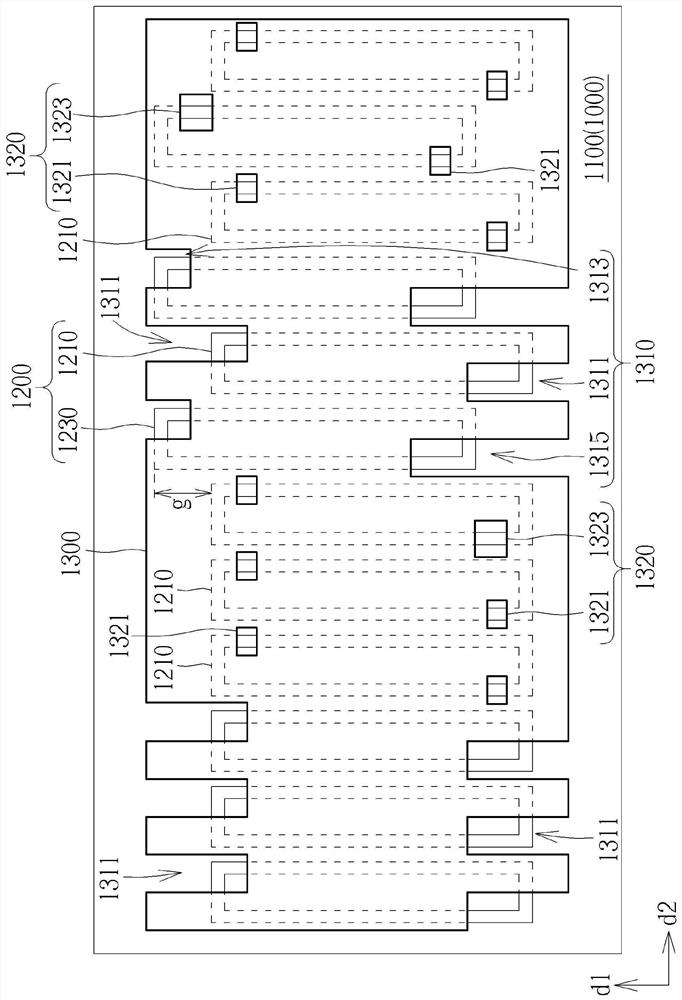

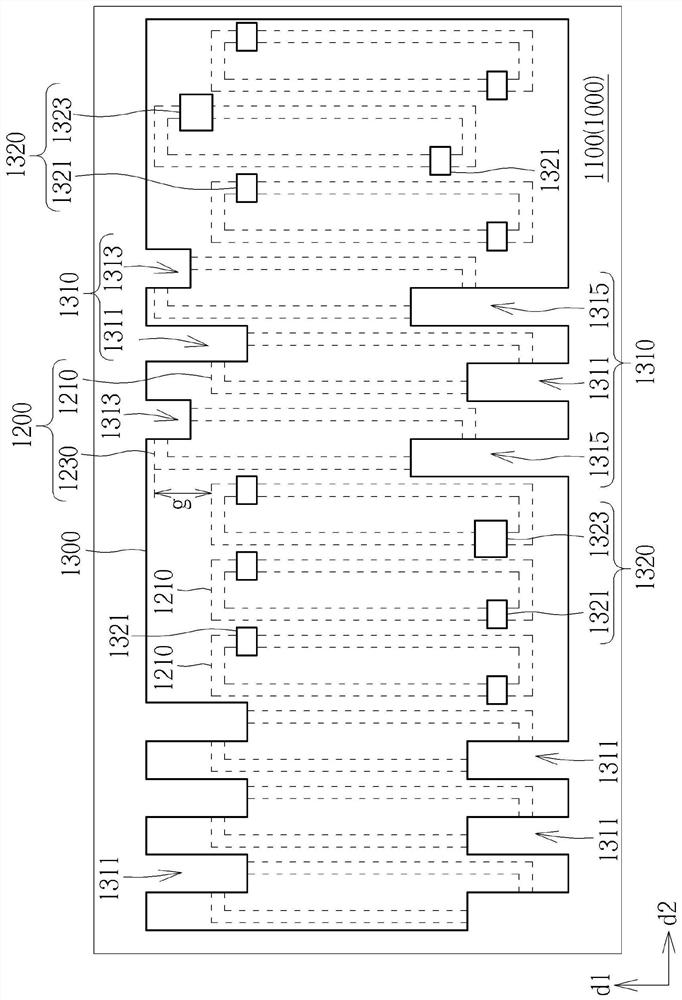

[0072] Please refer to Figure 1 to Figure 4 , which is a schematic diagram of a method for forming a semiconductor device in a preferred embodiment of the present invention. First, please refer to figure 1 As shown, a substrate 1000 is provided, and then, a material layer 1100 is formed on the substrate 1000 . The material layer 1100 includes, for example, a conductive material, such as a low-resistance metal material such as tungsten (tungsten, W), aluminum (aluminum, Al) or copper (copper, Cu), or a dielectric material, such as silicon oxide, Silicon nitride (SiN), silicon oxynitride (SiON) or ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com