Substrate structure suitable for flexible solar wing and forming method of substrate structure

A molding method and substrate technology, applied in the direction of chemical instruments and methods, synthetic resin layered products, lamination, etc., can solve the problems that the envelope size and weight cannot meet the requirements, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further elaborated below with reference to the accompanying drawings and embodiments.

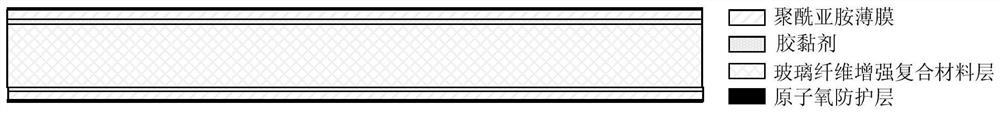

[0027] Incorporate references figure 1 , the flexible substrate provided by the present invention is also called the substrate structure of the solar wing, including:

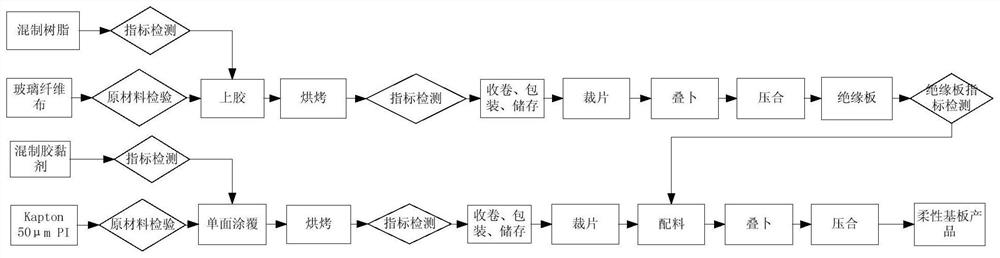

[0028] The flexible substrate is a five-layer symmetrical structure in cross-section, which combines the advantages of rigid boards and flexible boards, and has better mechanical properties and flexibility. The middle is the reinforcement layer, the upper and lower layers near the reinforcement layer are the adhesive layer, the outer side of the adhesive layer is the polyimide film layer, and the adhesive layer glues the reinforcement layer and the polyimide film layer into a whole .

[0029] In this embodiment, the reinforcing layer adopts SW110C-100a / SP120N high-strength glass fiber cloth reinforced epoxy resin matrix composite material, and the thickness of the polyimide film is 0.05...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical insulator | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com