Method and device for preparing filter aid in aluminum oxide production

A technology of filter aid and alumina, which is applied in chemical instruments and methods, feeding devices, preparation of alkaline earth metal aluminate/alumina/aluminum hydroxide, etc., which can solve the problems of increased production steam consumption and increased production costs , to achieve the effects of reducing evaporation steam consumption, low operating cost, and simple system structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

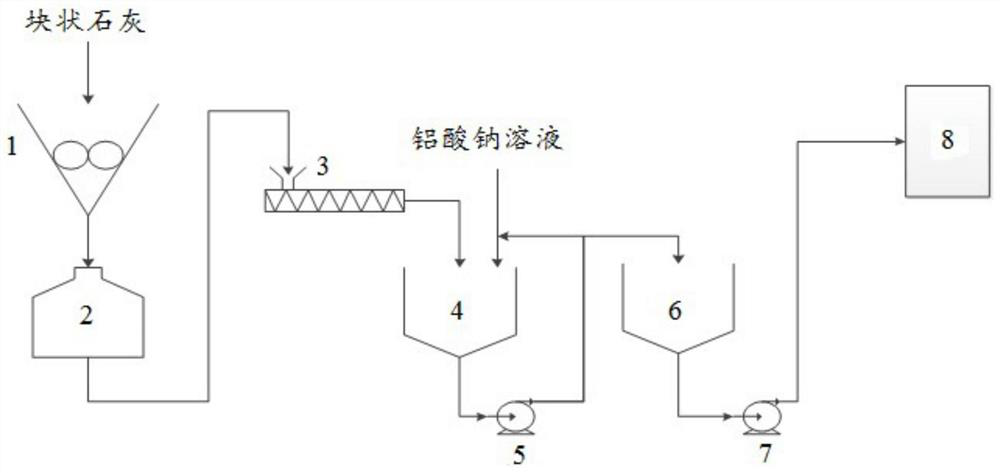

[0042] Taking an alumina plant as an example, its annual output is 1 million tons, its TCA lime consumption is 10Kg / t.AO, and its annual lime consumption is 10,000 tons. use as figure 1 In the process shown, block lime is ground to obtain lime powder with a fineness of -63um>70%, which is mixed with sodium aluminate solution and then reacted. Specifically, corresponding to 1 ton of lime powder, sodium aluminate solution is added The amount is 20-40m 3 , and the sodium aluminate solution stays in the residence tank for 4-8 hours, and then it is transported to the crude liquid tank, and after mixing with the crude liquid, it is sent to a leaf filter for fine filtration.

[0043] After testing, the method can meet the requirements of alumina production, and the practical application effect is good.

[0044] Effect comparison

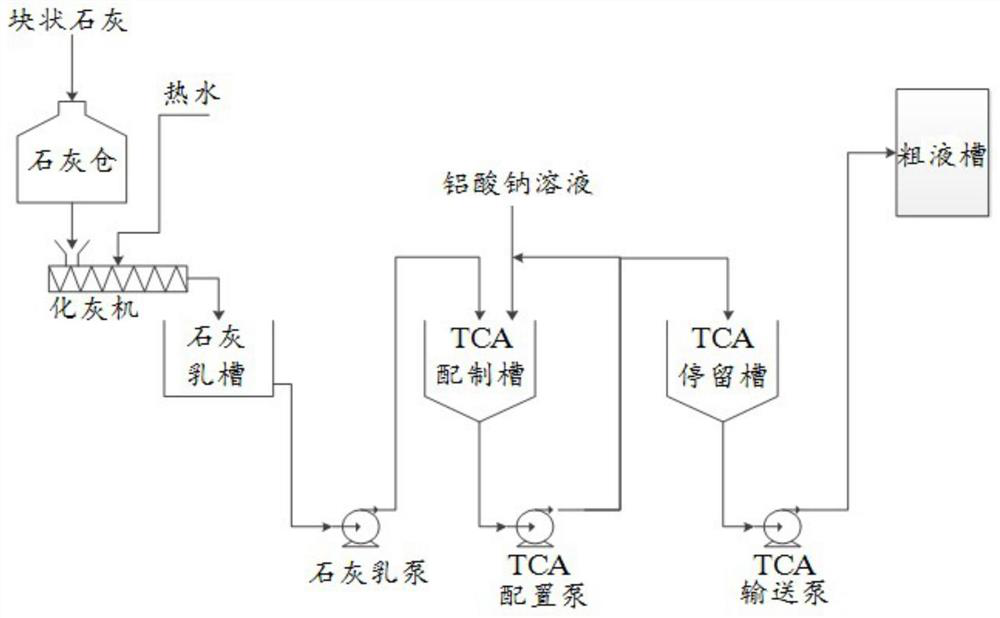

[0045] If using figure 2In the traditional process shown, block lime is crushed first to obtain lime powder, and then mixed to obtain lime milk. The s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com