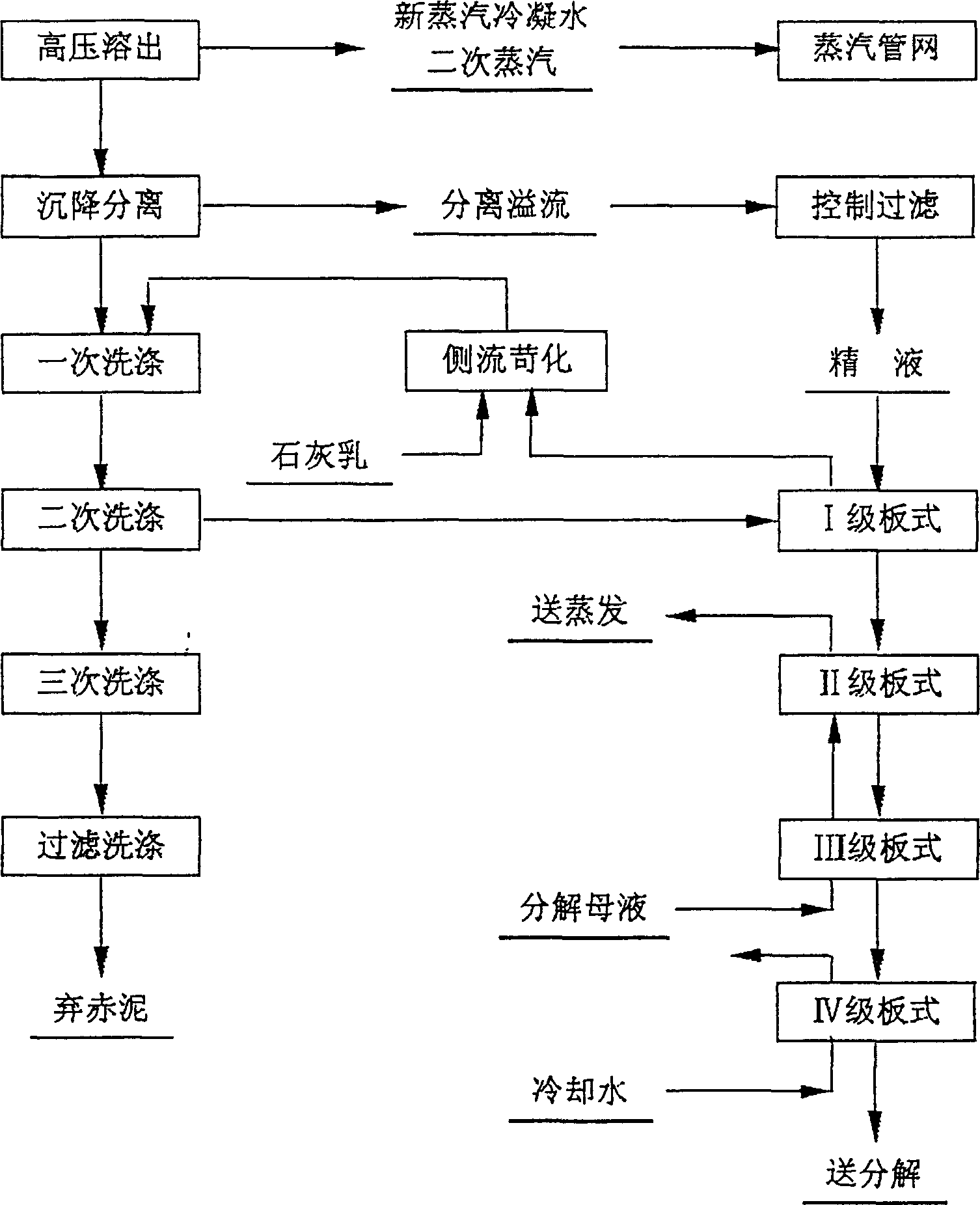

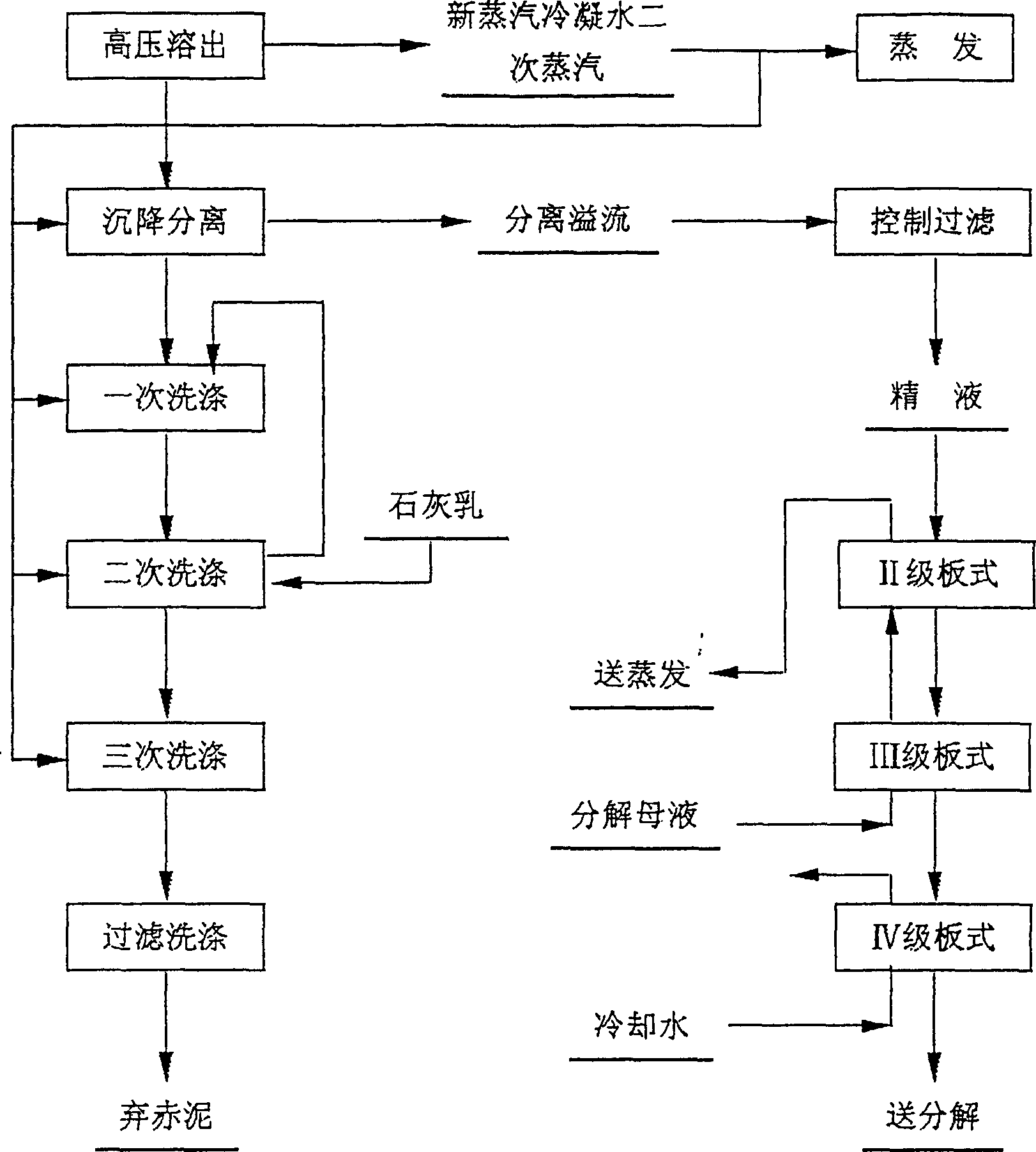

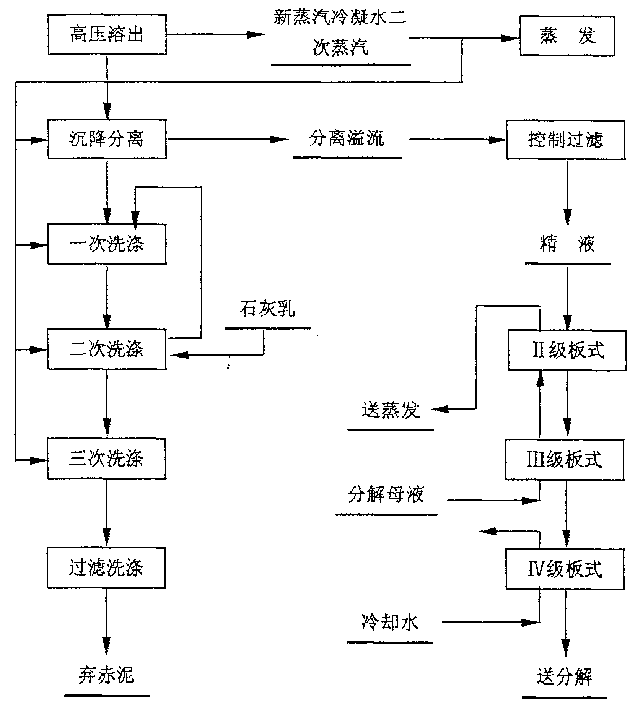

Directly heating and decomposing plate heat exchanging technology for alumina laterite washing

A plate heat exchange and alumina technology, which is applied in the preparation of alkali metal aluminate/alumina/aluminum hydroxide, etc., can solve the problem that the steam pipe network scheme cannot be realized, the leakage of condensed water flash tank, and the pressure fluctuation in the tank is large. and other problems, to achieve the effect of prolonging the chemical cleaning cycle, reducing the evaporation load and saving energy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0057] Dissolution of new steam condensed water secondary steam: temperature 165°C, pressure 6×10 5 pa, flow rate 25t / h

[0058] Among them, 15t / h is sent for evaporation, and 10t / h is sent for sedimentation and washing

[0059] Red mud washing and settling tank temperature: 100°C for one wash

[0060] Second wash 98℃

[0061] Three washes at 90°C

[0062] Plate heat exchange: Semen temperature: Plate inlet 108°C Level III outlet 75°C Plate outlet 62°C

[0063] Mother liquor temperature: Plate inlet: 55°C

[0064] Plate outlet: 95°C

example 2

[0066] Dissolution of new steam condensed water secondary steam: temperature 145°C pressure 3×10 5 pa flow 20t / h

[0067] Red mud washing and settling tank temperature: 95°C for one wash

[0068] Second wash at 95°C

[0069] Three washes at 85°C

[0070] Plate heat exchange: semen temperature: plate inlet 105°C, stage III outlet 65°C, plate outlet 58°C

[0071] Mother liquor temperature: Plate inlet: 50°C

[0072] Plate outlet: 92°C

[0073] The implementation of the present invention not only makes full use of the secondary steam of alumina dissolution, saves energy, but also finds a new process for red mud sedimentation washing and decomposition plate heat exchange, and simultaneously simplifies the process flow of these processes, improves operating conditions, and technology The index is optimized, so that the temperature of the evaporation stock solution is raised from 80°C to 92°C, reaching th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com