Slack coal pressure gasification wastewater recycling treatment method and treatment system as well as application

A technology for pressurized gasification and treatment of crushed coal, which is applied in the fields of oxidized water/sewage treatment, chemical instruments and methods, and reduced water/sewage treatment, etc. and other problems to achieve the effect of prolonging service life, high membrane flux, and strengthening biochemical treatment capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] This embodiment is used to illustrate the waste water recycling treatment method and treatment system of the crushed coal pressurized gasification of the present invention.

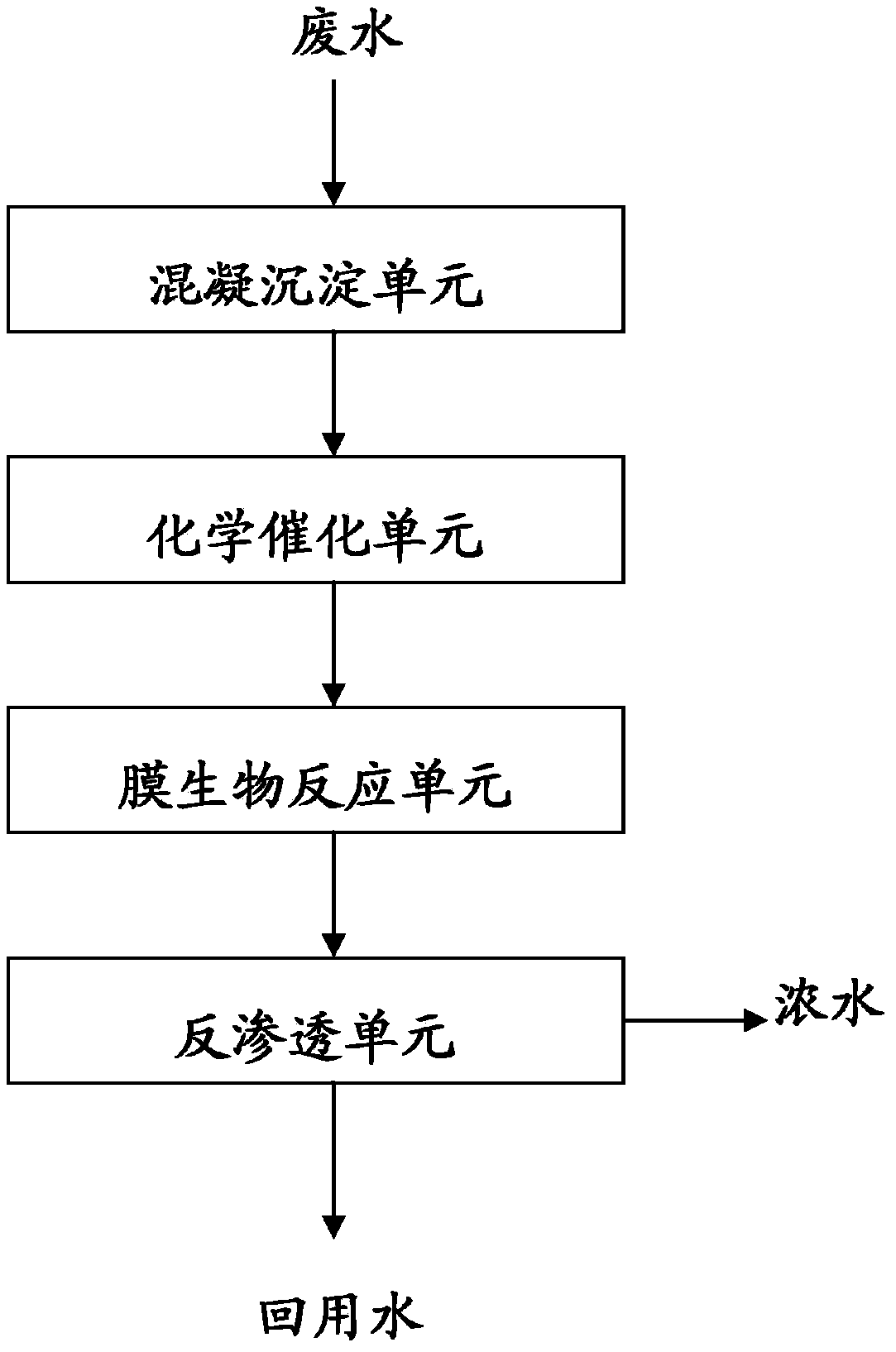

[0036] Such as figure 1 The shown crushed coal pressurized gasification waste water reuse treatment system includes a coagulation sedimentation unit, a chemical catalysis unit, a membrane biological reaction unit and a reverse osmosis unit connected in sequence. In actual construction, existing equipment and technologies with the above functions can be selected. For example, the coagulation-sedimentation unit can be a coagulation-sedimentation tank, the chemical catalysis unit can be a chemical catalysis reaction tank, and the membrane bioreaction unit can be a membrane bioreaction device (MBR), etc. The above-mentioned equipment and structures can be connected sequentially through pipelines.

[0037] The chemical catalytic unit can be equipped with an exhaust gas absorption device, which is fill...

Embodiment 2

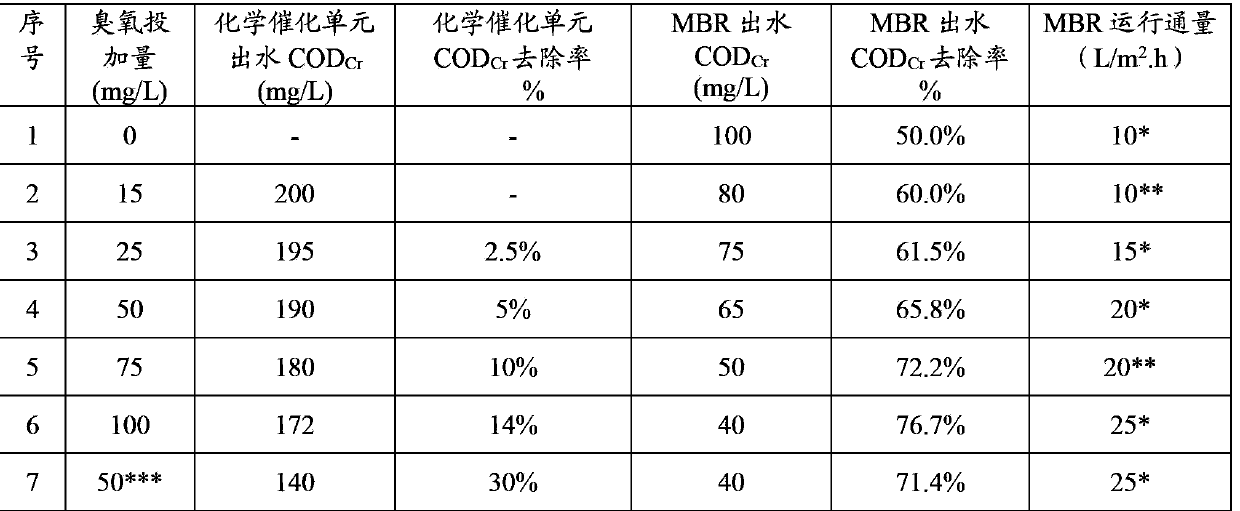

[0080] This example is used to illustrate the present invention's screening of ozone dosage.

[0081] The inventors found that the dosage of ozone can affect the treatment effect of wastewater. Therefore, the inventors studied the influence of different dosages of ozone on the process results. The operation steps and other parameters of this embodiment are basically the same as those of Embodiment 1, the difference is the dosage of ozone in the chemical catalytic unit. The test data are shown in Table 1 below.

[0082] Table 1 The effect of the dosage of ozone on the effect of wastewater treatment

[0083]

[0084] Note:

[0085] *: Process operating conditions: stop when running for 7 minutes, and air exposure for 2 minutes;

[0086] **: Process operating conditions: stop when running for 9 minutes, air exposure for 2 minutes;

[0087] ***: Ultrasound is added on the basis of ozone dosage of 50mg / L; ultrasonic treatment is added (ultrasonic frequency: 25~35kHz)

[00...

Embodiment 3

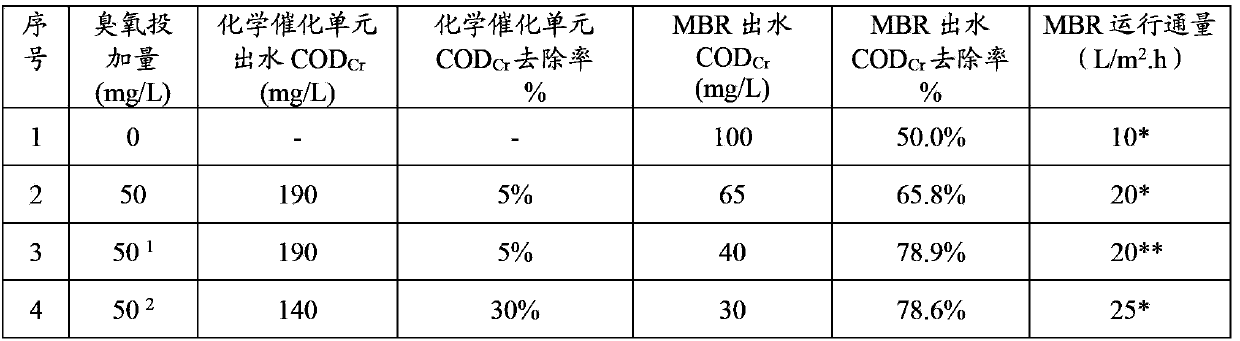

[0090] This example is used to illustrate the screening of microorganisms in the membrane bioreaction according to the present invention.

[0091]The inventors also studied the influence of microorganisms in the membrane bioreaction on the treatment effect. Similarly, the operating steps and other parameters of this embodiment are basically the same as those of Embodiment 1, except that the microbial strains that degrade phenol are introduced into the MBR. The test data are shown in Table 2 below.

[0092] Table 2 Effect of microorganisms on wastewater treatment effect

[0093]

[0094] Note:

[0095] *: Stop running when running for 7 minutes, and air exposure for 2 minutes;

[0096] **: When running for 9 minutes, it needs to stop running, and air exposure for 2 minutes;

[0097] 1: Introduce phenol-degrading microbial strain UW7 strain of phenol-degrading bacteria;

[0098] 2: On the basis of ozone dosage of 50mg / L and ultrasonic wave (frequency 25-35kHz), introduce...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com