Preparation method of lanthanum hydroxide modified aerogel phosphorus removal adsorbent

A technology of lanthanum hydroxide and phosphorus adsorbent, which is applied in the field of water pollution treatment, can solve the problems of limited application and low mechanical properties, and achieve the effects of fast adsorption speed, good mechanical properties and high specific adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

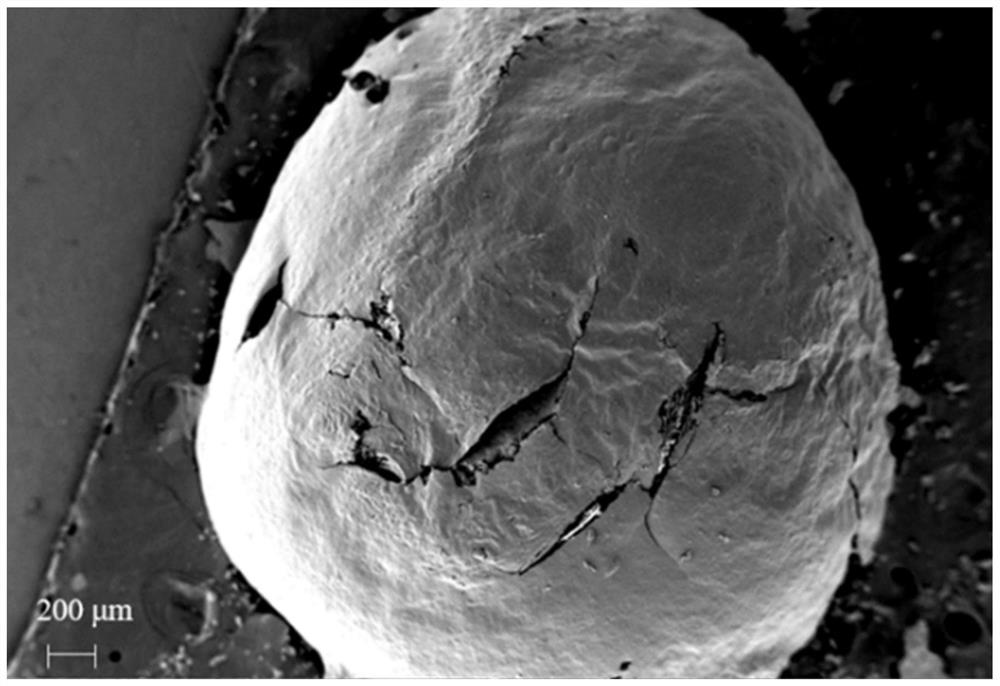

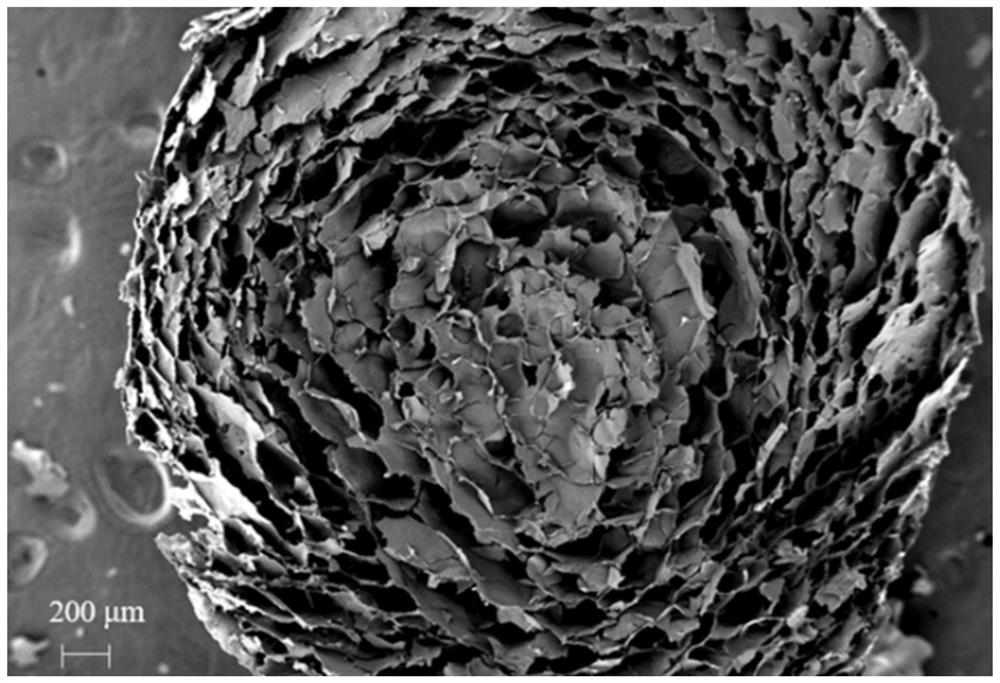

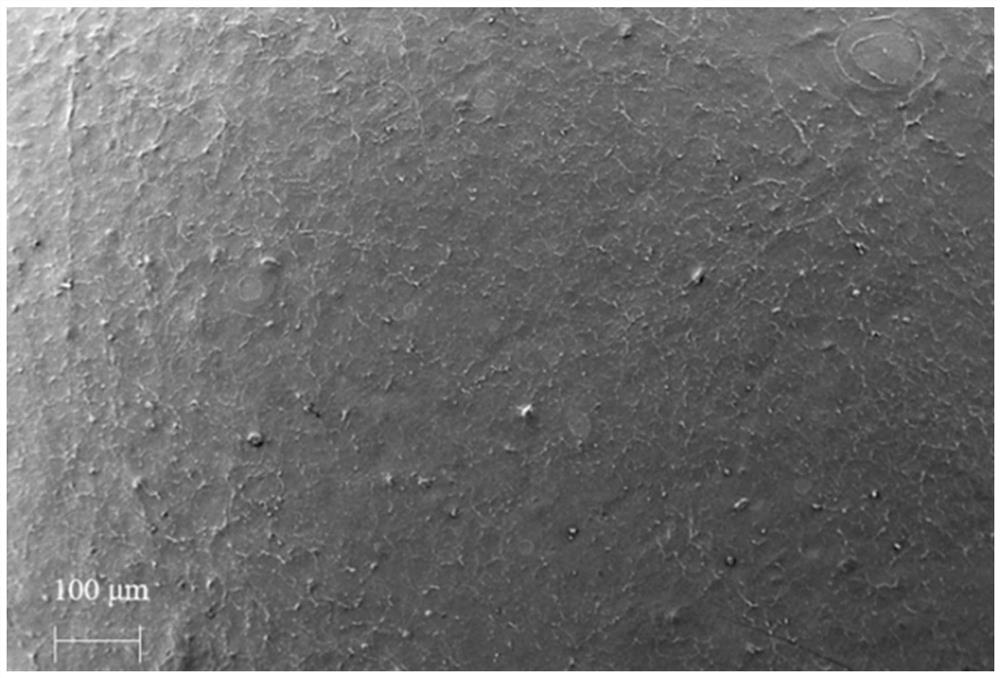

Image

Examples

specific Embodiment approach 1

[0037] Specific embodiment one: the preparation method of lanthanum hydroxide modified airgel dephosphorization adsorbent in this embodiment is carried out according to the following steps:

[0038] 1. Synthesis of lanthanum hydroxide modified hydrogel beads:

[0039] ①. Dissolving graphene oxide in deionized water and ultrasonically dispersing to obtain a graphene oxide dispersion;

[0040] ②. Dissolving lanthanum hydroxide in deionized water to obtain an aqueous solution of lanthanum hydroxide; dissolving sodium alginate in deionized water to obtain an aqueous solution of sodium alginate;

[0041] ③, mixing the dispersion of graphene oxide, lanthanum hydroxide aqueous solution and sodium alginate aqueous solution, stirring vigorously at room temperature to obtain a mixed solution;

[0042] ④. Under normal temperature conditions, add a cross-linking agent aqueous solution drop by drop into the mixed solution obtained in step ③ to obtain hydrogels, and then let stand for 18-2...

specific Embodiment approach 2

[0048] Embodiment 2: This embodiment differs from Embodiment 1 in that: Step 1 ① The ultrasonic dispersion process is: ultrasonication for 10 min to 30 min at an ultrasonic power of 100W to 500W.

specific Embodiment approach 3

[0049] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the mass fraction of graphene oxide in the graphene oxide dispersion in step ① is 0.2-0.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com