Flotation separation method for multi-component waste plastic

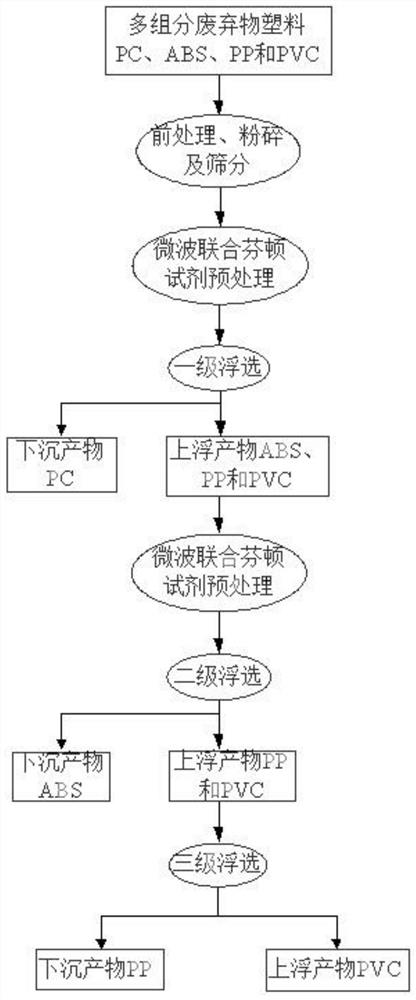

A separation method and multi-component technology, applied in the direction of plastic recycling, mechanical material recycling, recycling technology, etc., to achieve continuous and efficient separation, wide application range, and increase the effect of reaction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062] This embodiment includes the following steps:

[0063] Step 1. Pre-treatment: Soak multi-component waste plastics in tap water containing detergent for 20 minutes to remove grease, then rinse with tap water for 3 times, then soak in tap water for 5 minutes, take it out, place it on filter paper and let it dry naturally at room temperature Air-dried; the multi-component plastic includes polycarbonate, acrylonitrile-butadiene-styrene copolymer, polypropylene and polyvinyl chloride in a mass ratio of 1:1:1:1, and the multi-component plastic comes from household Plastic products of electrical refrigerators, washing machines, air conditioners, and TV casings;

[0064] Step 2, crushing and screening: the multi-component waste plastics that have been naturally air-dried in step 1 are crushed with a pulverizer, and then sieved to obtain multi-component waste plastic particles; the multi-component waste plastics The particle size of the particles is 4mm ~ 6mm;

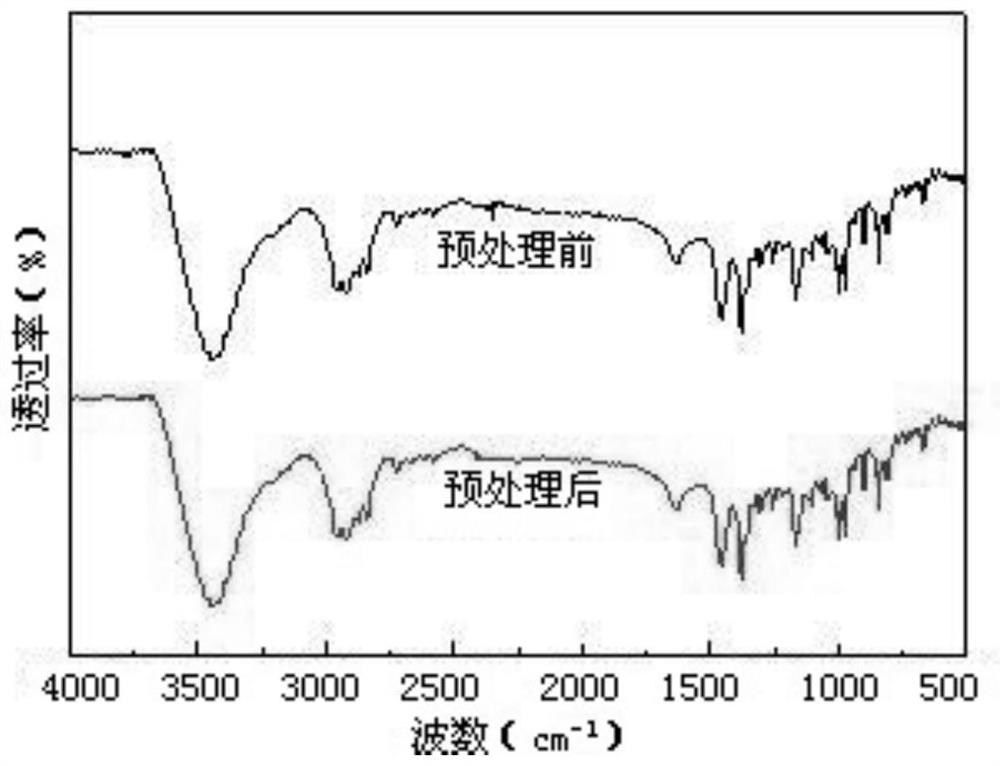

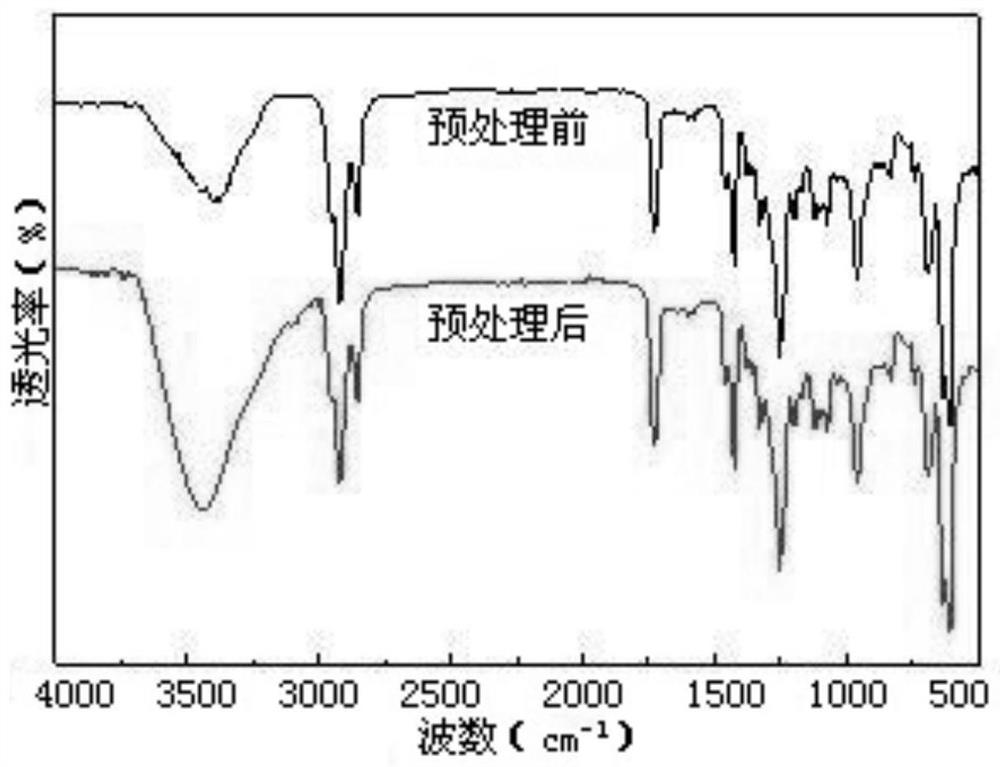

[0065] Step 3....

Embodiment 2

[0094] This embodiment includes the following steps:

[0095] Step 1. Pre-treatment: Soak the multi-component waste plastic in tap water containing detergent for 15 minutes to remove grease, then rinse it repeatedly with tap water 4 times, then soak in tap water for 4 minutes, take it out, place it on filter paper and let it dry naturally at room temperature Air-dried; the multi-component plastic includes polycarbonate, acrylonitrile-butadiene-styrene copolymer, polypropylene and polyvinyl chloride in a mass ratio of 1:1:1:1, and the multi-component plastic comes from household Plastic products of electrical refrigerators, washing machines, air conditioners, and TV casings;

[0096] Step 2, crushing and screening: the multi-component waste plastics that have been naturally air-dried in step 1 are crushed with a pulverizer, and then sieved to obtain multi-component waste plastic particles; the multi-component waste plastics The particle size of the particles is 4mm ~ 6mm;

[...

Embodiment 3

[0114] This embodiment includes the following steps:

[0115] Step 1. Pre-treatment: Soak the multi-component waste plastic in tap water containing detergent for 10 minutes to remove grease, then rinse it repeatedly with tap water 5 times, then soak in tap water for 3 minutes, take it out, place it on filter paper and let it dry naturally at room temperature Air-dried; the multi-component plastics include polycarbonate, acrylonitrile-butadiene-styrene copolymer, polypropylene and polyvinyl chloride in a mass ratio of 1:2:1:2, and the multi-component plastics are from household Plastic products of electrical refrigerators, washing machines, air conditioners, and TV casings;

[0116] Step 2, crushing and screening: the multi-component waste plastics that have been naturally air-dried in step 1 are crushed with a pulverizer, and then sieved to obtain multi-component waste plastic particles; the multi-component waste plastics The particle size of the particles is 4mm ~ 6mm;

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com